[ad_1]

On this version of Sliced, the 3D Printing Business information digest, we cowl the most recent enterprise developments, partnerships, and acquisitions within the additive manufacturing sector.

At this time’s version options new supplies, partnerships, and enterprise offers, and Balena and designer Kitty Shukman crafting compostable 3D printed slide.

Learn on for the newest updates from IperionX, Boston Micro Fabrication, 3YOURMIND, Tri-Tech 3D, and extra.

Don’t neglect to make your nominations for the 2023 3D Printing Business Awards, the deadline is approaching quick.

Enterprise offers and acquisitions from IperionX, Sigma Additive Options, AML3D, and extra

Diving into enterprise offers and acquisitions, IperionX has introduced an settlement with the U.S. Military Fight Capabilities Improvement Command Floor Car Techniques Heart (DEVCOM GVSC) to judge the ballistic testing properties of their high-strength titanium plate parts. DEVCOM GVSC could share the outcomes with key U.S. Division of Protection (DoD) contractors, together with Common Dynamics Land Techniques, BAE Techniques, American Rheinmetall Protection, Oshkosh Company, and AM Common, for potential integration into future U.S. Military floor car designs. IperionX will make the most of powder metallurgy and its superior titanium angular powder, together with patented Hydrogen Sintering and Part Transformation (HSPT) applied sciences, to fabricate the titanium plates, enhancing their efficiency and sturdiness. This collaboration aligns with the DoD’s efforts to cut back reliance on overseas titanium imports and set up a self-sustaining, environment friendly home titanium provide chain for crucial protection methods.

“We’re honored to collaborate with DEVCOM GVSC to judge our titanium merchandise for U.S. Military floor automobiles. Titanium for the U.S. protection sector is at the moment sourced over lengthy distances from overseas nations. IperionX plans to re-shore a decrease price and extra sustainable absolutely built-in U.S. titanium provide chain that’s crucial to America’s financial future and nationwide safety,” stated Anastasios (Taso) Arima, IperionX CEO.

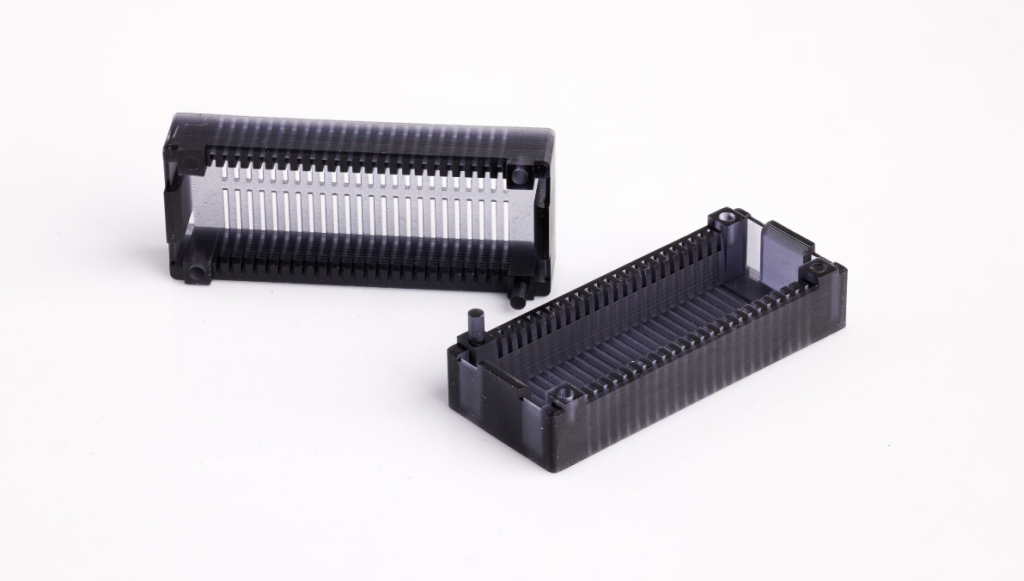

Adopted by Boston Micro Fabrication (BMF) has certified Mechnano’s Formula1µ resin for its 10 micron S240 printers and the most recent 25 micron microArch S350 3D printer platform. Formula1µ is a static-dissipative resin superb for quick and inexpensive half fabrication in sub-90°C environments. Researchers and producers can now create prototypes, manufacturing aids, and end-use elements with electrostatic dissipative (ESD) properties. Mechnano’s Formula1µ relies on proprietary Carbon Nanotube know-how, making certain excessive decision and isotropic properties.

Sigma Additive Options has introduced the acquisition of NextTrip, a journey know-how firm, via a non-binding letter of intent (LOI). The deal includes Sigma Additive Options issuing shares initially constituting 19.99% of its widespread inventory, with extra shares tied to NextTrip’s efficiency milestones, valuing the transaction at round $48 million. This transfer positions NextTrip for a Nasdaq itemizing. Concurrently, Sigma has signed an LOI to promote mental property belongings associated to its additive high quality assurance product. These strategic actions purpose to reinforce shareholder worth, with NextTrip poised to leverage its standing as a public firm for capital and progress alternatives.

World manufacturing market Xometry‘s Thomas has launched “Construct America, Purchase America” (BABA) certification to its listing, Thomasnet.com, that includes over 500,000 suppliers. Home producers can now sign their adherence to the BABA initiative, a crucial a part of the Infrastructure Funding and Jobs Act (IIJA). BABA mandates federally funded infrastructure initiatives to supply U.S.-made supplies and merchandise. Xometry goals to strengthen the home provide chain by facilitating connections between main corporations and BABA-compliant suppliers, supporting American producers and the U.S. economic system. Suppliers can simply declare their BABA compliance on Thomasnet.com, North America’s largest industrial sourcing platform with practically 500,000 U.S.-based suppliers.

“Our purpose is to assist main corporations seamlessly join with BABA-compliant suppliers to additional strengthen our home provide chain and supply continued help to American producers,” stated Randy Altschuler, CEO of Xometry, guardian firm to Thomas. “America’s 600,000 small- and mid-size producers are the spine of our home economic system and are deeply ingrained of their communities. Supporting them is a win for the American employee, for our neighbors and for our nation.”

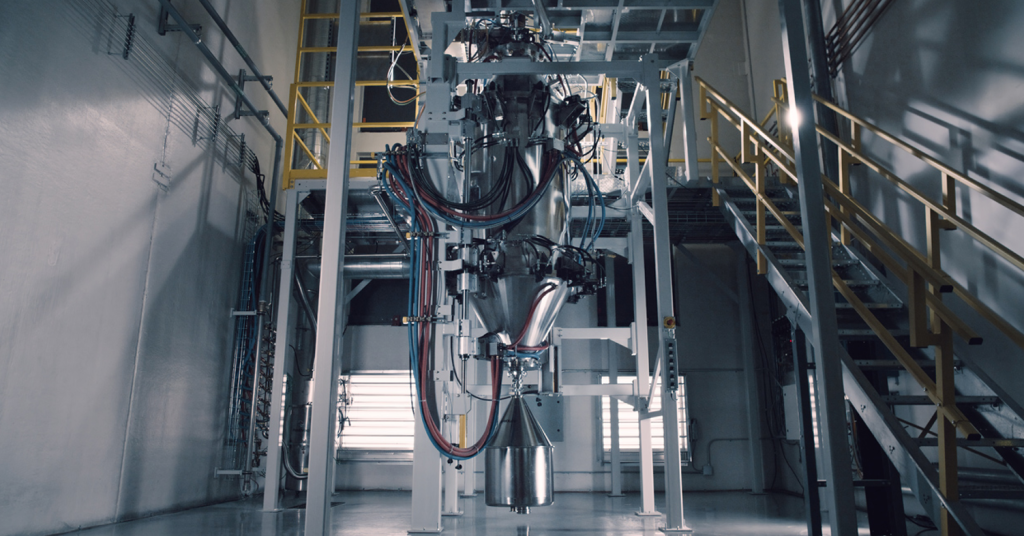

Australian large-format 3D printer producer AML3D has secured its first order for a 2600 Version ARCEMY system from Laser Welding Options (LWS), positioning LWS as a provider of Nickel Aluminum Bronze (NAB) parts to the US Navy’s Submarine Industrial base. The ARCEMY system, AML3D’s smallest industrial-scale steel 3D printer, will produce NAB parts tailor-made for US Navy functions. The 12-month lease, valued at roughly A$0.27 million (US$0.22 million), contains software program licensing and technical help. LWS can choose to buy the system at any time through the lease or it will likely be out there for redeployment to additional help AML3D’s US scale-up technique. This transfer goals to expedite LWS’ entry into ARCEMY manufacturing, with the system set to function in Houston, Texas, inside 8 to 10 weeks. The settlement helps AML3D’s technique of embedding ARCEMY methods inside US Navy suppliers as a part of its US scale-up efforts within the thriving additive manufacturing market.

World requirements group ASTM Worldwide has inked a memorandum of understanding (MoU) with South Korea’s 3D Fusion Business Affiliation (3DFIA). The settlement was formalized through the tenth ASTM Worldwide Additive Manufacturing Heart of Excellence (AM CoE) Snapshot Workshop, co-hosted with 3DFIA. Held in Incheon, South Korea, and coinciding with ASTM F42/ISO TC261 joint conferences, the workshop convened business leaders and specialists. Dr. Mohsen Seifi, ASTM Worldwide’s VP of worldwide superior manufacturing packages, and Chungwon Park, 3DFIA president, signed the MoU. It encompasses coaching, analysis initiatives, and advisory companies to bolster worldwide collaboration between ASTM and South Korea’s AM business.

whatt.io Inc, originating from Lostboyslab, has joined the 3MF Consortium as an affiliate member. With experience in additive manufacturing and micro-factory operations, whatt.io goals to advance digital manufacturing. The 3MF (3D Manufacturing Format) is an open-source file format designed for future manufacturing, making certain exact 3D mannequin descriptions and overcoming limitations of conventional codecs. The 3MF Consortium, a collaboration of business leaders, works to determine a common, high-fidelity format for 3D printing and digital manufacturing. whatt.io’s purpose is to reinforce digital product passport options, significantly for spare elements. It’s introducing the ‘3MF Vault’ resolution, transitioning from Proof of Idea to a completely built-in SaaS resolution, increasing 3MF format capabilities with metadata inclusion, like copyright and possession particulars.

“With 3MF, we’re offered with extra expansive alternatives to guard the mental property and copyrights of digital manufacturing information. This stands as probably the most formidable challenges within the path of digital manufacturing’s evolution,” says Founder and CEO, Stefan Larsson for whatt.io.

Moreover, 6K Additive, a subsidiary of 6K, has secured a 5-year Blanket Buy Settlement (BPA) from the Military Contracting Command in help of the US Military Improvement Command (DEVCOM). This BPA will bolster weapons R&D efforts at DEVCOM, catering to the rising demand for prototypes and low-rate preliminary manufacturing (LRIP). The settlement covers entities at a number of places, together with Picatinny Arsenal in NJ, Benet Labs in NY, Adelphi Laboratories in MD, and Rock Island Arsenal in IL. 6K Additive employs its proprietary UniMelt microwave plasma platform to provide steel powders, enabling the transformation of high-value steel scrap into aerospace-grade powders, together with strategically important metals equivalent to nickel and titanium. This sustainable home provide ensures materials safety, high quality, and consistency for the US navy whereas expediting superior methods growth and price administration.

Rising partnerships from 3YOURMIND, Koenigsegg Automotive, Black Buffalo 3D, and extra

Now continuing with partnership information, 3D printing software program developer 3YOURMIND and Phillips Corp. Federal Division have introduced their partnership with Marine Corps System Command’s Superior Manufacturing Operations Cell (AMOC) to reinforce digital additive manufacturing capabilities. They plan to combine 3YOURMIND’s half identification software program with the Digital Manufacturing Information Vault (DMDV), a central repository for Marine Corps information and designs, with the purpose of bettering AMOC’s operations. This collaboration goals to streamline the approval of spare elements for subject use, aligning with the DoD’s mission to strengthen provide chains and leverage additive applied sciences for legacy tools sustainability. Following a profitable first-year contract, the $2.5 million AMOC award marks the continuation of their journey.

Subsequent up, Additive manufacturing service supplier BEAMIT SpA, and Constellium, a worldwide chief in aluminum options, have signed a letter of intent to collaborate on superior aluminum options. This partnership goals to leverage their experience in additive manufacturing and aluminum throughout numerous industries. Their joint efforts will concentrate on in depth analysis and growth to reinforce aluminum properties for additive manufacturing processes. BEAMIT’s additive manufacturing proficiency, mixed with Constellium’s alloy information, will expedite the event and commercialization of superior aluminum options. This collaboration seeks to fulfill the demand for light-weight, high-strength supplies whereas prioritizing sustainability via aluminum’s recyclability and light-weight properties, marking a milestone in additive manufacturing’s evolution.

“We’re thrilled to associate with Constellium, a acknowledged world chief in aluminium options, to advance the event of superior aluminium supplies for additive manufacturing,” stated Gabriele Rizzi, Common Supervisor of BEAMIT SpA. “By combining our additive manufacturing experience with Constellium’s deep information of aluminium alloys, we purpose to ship groundbreaking options that can allow new prospects in a variety of industries.”

Swedish sports activities automobile producer Koenigsegg Automotive has enhanced its 3D printing processes and printer administration by integrating the cloud-based 3DPrinterOS platform. The corporate has seen substantial progress in its 3D printer depend, totaling 17 machines, together with 11 FDM printers and numerous resin-based printers, over the previous 2.5 years. 3DPrinterOS presents versatility, permitting engineers to seamlessly change between completely different printer sorts for particular duties, bettering effectivity and high quality. Actual-time monitoring and centralized administration have additionally boosted productiveness and profitability, optimizing Koenigsegg’s 3D printing actions, with key contributions from specialists Tim Bäck and Kristian Ljungkvist.

Building 3D printing firm Black Buffalo 3D has entered a MoU with Saudi Readymix Concrete Co., producer of ready-mix merchandise in Saudi Arabia. The collaboration goals to fabricate Black Buffalo 3D’s proprietary structural ink utilizing native supplies and develop regional 3D development printing supplies, mixes, and extra ink formulation. By partnering with Saudi Readymix, Black Buffalo 3D intends to create dependable, sustainable, and regionally produced ink for 3D development printers. This ink can be used within the area to print housing, industrial buildings, and infrastructure parts, with a concentrate on assembly native constructing code requirements to advertise adoption in Saudi Arabia. The regional distribution associate, Presidio Advisors in Dubai, will present extra help to certified builders.

“We’re extraordinarily proud to announce the signing of an MoU with the Black Buffalo 3D and to fabricate confirmed supplies to additional adoption and development of 3D printers to construct houses, buildings and wanted infrastructure all through the Kingdom of Saudi Arabia,” said Chris Leptokaridis, Technical & Technique Director of Saudi Readymix Concrete Co.

Specialty chemical compounds firm Evonik and LEHVOSS Group, a chemical and mineral specialties group, have joined forces in industrial 3D printing. LEHVOSS will develop its 3D printing formulations utilizing Evonik’s PA613 polymer chemistry below the LUVOSINT model. It’ll incorporate Evonik’s INFINAM PA 6005 P (PA613) polymer powder into their product vary. This collaboration goals to unlock new automotive sector functions. INFINAM PA 6005 P, based mostly on polyamide 613, fits 3D functions in higher-temperature settings and options low water absorption, enhancing processability and dimensional stability. LEHVOSS now presents each unreinforced and carbon-fiber-reinforced variants from a single supply of their LUVOSINT product traces, tailor-made to numerous 3D printing processes.

Moreover, 6K Power and Forge Nano have signed a five-year buy and provide settlement for 6K Power’s domestically produced NMC 811 cathode lively materials (CAM), which Forge Nano will use for battery cell manufacturing. This partnership goals to produce battery cells for numerous functions, together with the DoD, aerospace, and fleet operations. 6K Power’s NMC 811 can be produced at its PlusCAM manufacturing unit, a sustainable, multi-chemistry battery materials manufacturing plant set to open in late 2024. This facility will profit from 6K’s UniMelt microwave plasma know-how, recognized for its sustainability and decreased environmental impression in comparison with conventional strategies.

“The Inflation Discount Act’s purpose of securing America’s place as a world chief in home clear power manufacturing depends closely on our nation’s skill to produce lithium-ion batteries on US soil. This settlement is a crucial first step for our business and one which we imagine will strengthen home provide chains for lithium-ion battery manufacturing in america,” stated 6K Power President Sam Trinch. “Each organizations are keenly centered on delivering a 100% home provide chain for lithium-ion batteries to remove the dependence on overseas sources.”

Polish startup GREENFILL3D has partnered with COLORISED, an inside design platform, to create a particular line of lamps known as ECO Lamps. These lamps boast distinctive shapes and colours and are crafted from biodegradable and compostable supplies, together with polylactide, polylactide infused with wheat bran, and absolutely compostable thermoplastic starch. ECO Lamps are biodegradable below industrial circumstances and could be composted at house. They’re produced utilizing licensed bioplastics from main Polish corporations. The lamps are grouped into two classes: Kolora Spektro and Brilanta Brano, every providing a variety of colours and patterns, and include color-matched fabric-coated energy cables and LED bulbs.

New supplies from Tri-Tech 3D, Carbon, and extra

Adopted by supplies information, UK Stratasys 3D printing options supplier, Tri-Tech 3D, is providing Polyamide (PA) 12 as a Selective Absorption Fusion (SAF) materials. PA12 is a flexible polymer superb for numerous functions, together with shopper items, automotive elements, and equipment parts. It presents cost-effective manufacturing with improved thermal management, main to raised half consistency and complex geometries. Customers can effectively nest end-use elements, leading to decrease prices and sooner turnaround for higher-volume manufacturing. It additionally gives effective characteristic decision, making it appropriate for creating sturdy, purposeful, and exact parts. PA12 is appropriate with the Stratasys H350 3D Printer, providing industrial-grade SAF know-how for correct, constant, and high-production-rate output.

“After listening to suggestions about PA11 from customers, its nice to see that customers now have entry to the most effective powder mattress materials available on the market,” defined Robert Pitts, gross sales supervisor at Tri-Tech 3D. “Its thermal management and chemical stability improves half consistency, making it viable for a variety of functions each for prototyping and mass manufacturing, together with complicated end-use elements, manufacturing aids and automotive elements.

US 3D printer OEM Carbon has unveiled its newest elastomer materials, EPU 46. This versatile materials presents high-performance properties, superior sturdiness, and a wide selection of colour choices, making it superb for creating premium merchandise like saddles, footwear, and grips. EPU 46 is designed to fulfill numerous business calls for, emphasizing efficiency, consolation, aesthetics, and extra. It permits for materials stiffness changes with out compromising printability or inherent properties. Moreover, EPU 46 contributes to Carbon’s sustainability efforts, containing 40% bio-based materials and designed for solvent-free spin cleansing and resin reclaim to reduce waste. This elastomer combines velocity, customization, colour fastness, and elevated stiffness choices, making it appropriate for numerous functions.

AMALLOY, an aluminum alloy powder developed by the Know-how Innovation Institute (TII) for additive manufacturing, debuted on the AM Conclave convention in Abu Dhabi. This Center Jap-designed steel feedstock is optimized for laser beam powder mattress fusion (PBF-LB) methods, providing cost-effectiveness and excessive power with wonderful printability. In comparison with industrial AlSi10Mg alloys, AMALLOY gives a 33% power improve whereas sustaining ductility. Its distinctive chemical composition and metallurgical properties end in low susceptibility to scorching cracking, enabling greater strengths with out cracking. Additional developments and functions are underway, emphasizing versatility throughout industries.

Depowdering know-how specialist Solukon has launched an automatic powder assortment unit for environment friendly and secure dealing with of extra powder after depowdering processes, significantly in bigger methods and serial manufacturing just like the SFM-AT1000-S. The Solukon Powder Assortment Unit (SFM-PCU) makes use of an built-in vacuum conveyor system to move extra powder to a big container, bettering effectivity and security. Customers not want direct contact with the powder throughout depowdering, enhancing occupational well being and security compliance. The vacuum conveyor comes from Piab, a trusted associate for Solukon’s powder conveyors. Solukon is showcasing the SFM-PCU at Formnext 2023, highlighting its potential for big elements and automatic serial manufacturing.

Financials information from Ahead AM, and Xi’an Brilliant Laser Applied sciences

In H1 2023, Ahead AM, a subsidiary of BASF, has skilled substantial progress, reaching a 39% improve in efficiency and a 51% rise in materials enterprise in its steady portfolio in comparison with H1 2022. This strong efficiency aligns with a projected 19% compound annual progress charge (CAGR) for the 3D printing business in 2023. Ahead AM emphasizes collaborative business partnerships to reinforce buyer worth via novel supplies, functions, and processes whereas addressing world market wants. Providing over 800 machine/materials combos, Ahead AM stands because the premier unbiased supplier of complete supplies and options. Their concentrate on ecological sustainability enhances their long-term technique, emphasizing profitability and sustainability via course of optimization. In H2 2023, Ahead AM continues its dedication to selling AM adoption throughout industries, delivering superior supplies and companies.

Xi’an Brilliant Laser Applied sciences (BLT) has reported sturdy monetary outcomes for H1 2023, showcasing its rising demand and strong monetary place. With a 58.53% improve in working revenue YoY, totaling round $60.22 million, the corporate has achieved a internet revenue of roughly $2.44 million. BLT has efficiently expanded its presence within the aerospace and aviation sector, collaborating with main world aerospace gamers. Moreover, the corporate has ventured into the patron market and is making strides in electronics. BLT continues to concentrate on mass manufacturing capabilities and is increasing its manufacturing capability to fulfill rising demand.

Software program information from Markforged Holding Company, SelectAM, and Artec 3D

3D printer producer Markforged has unveiled Digital Supply, an on-demand platform enhancing half administration by enabling the licensed 3D printing of licensed elements as wanted. Producers can add digital half designs, securely licensing them to shoppers, distributors, and producers. Customers can then print these elements onsite or by way of licensed service suppliers. BMF, an early adopter, changed as much as 60 parts each three to 4 months of their sandblasting machines. Digital Supply lowers stock prices, streamlines replacements, and promotes sustainability. Challenge DIAMOnD, the world’s largest emergency response community for 3D printing, plans to implement Digital Supply to additional AM adoption.

Finnish AM software program firm SelectAM has launched an end-to-end workflow from AM half identification to supply. The AI-powered platform, out there as a free open-access model, allows customers to evaluate CADs and part-related information, obtain instantaneous AM worth quotes, estimate financial savings in comparison with typical manufacturing, and extra. Customers can entry premium options with a subscription, permitting them to simulate processes, calculate manufacturing prices, and discover the most effective AM know-how for his or her elements. The platform streamlines half identification and qualification for AM, saving time and simplifying the ordering course of for numerous AM applied sciences and supplies.

Luxembourg-based 3D scanner producer Artec 3D has unveiled Artec Studio 18 (AS18), enhancing the capabilities of its 3D scanners and information processing software program. AS18 options distinctive capabilities, together with the seamless merging of multi-resolution datasets from numerous Artec 3D scanners and fast information processing. The software program additionally incorporates AI to create lifelike colour 3D fashions. AS18 streamlines reverse engineering and high quality inspection duties, providing instantaneous defect identification and compliance with business tolerances. The software program is licensed by the German requirements authority PtB for its 3D metrology capabilities. With its enhanced options and AI-powered texture enhancement, AS18 goals to unlock alternatives throughout numerous industries.

“Artec Studio 18 unlocks new prospects, permitting customers to mix information from solely completely different scanners on the click on of a button,” stated Artwork Yukhin, President and CEO of Artec 3D. “With the hand held Artec Leo and long-range Artec Ray II, it’s now attainable to create extremely detailed digital twins of big areas like manufacturing unit flooring. This innovation, together with advances within the AI we use to enhance scan velocity and high quality, exhibits how we proceed to be pioneers within the 3D subject.”

Renishaw’s Sir David McMurtry awarded I-Kind Superior Manufacturing Excellence Award 2023

Sir David McMurtry, the Co-Founder and Government Chairman of Renishaw, a worldwide engineering applied sciences agency, has been honored with the I-Kind Superior Manufacturing Excellence Award 2023. This accolade, bestowed on the 72nd CIRP Common Meeting held at College Faculty Dublin, acknowledges McMurtry’s notable contributions to superior manufacturing innovation and analysis spanning many years. With 2023 marking the fiftieth anniversary of Renishaw’s founding, this award underlines McMurtry’s dedication to engineering fields, together with dimensional metrology and steel additive manufacturing (AM). The I-Kind Superior Manufacturing Analysis Centre, that includes Renishaw’s RenAM 500 collection steel AM system, highlights the corporate’s dedication to collaborative analysis in superior manufacturing.

“We satisfaction ourselves on contributing to the worldwide superior manufacturing analysis and innovation business”, stated Will Lee, Chief Government at Renishaw. “This can be a nice honour for Sir David and Renishaw, and our purpose is to have the ability to proceed making a optimistic impression on manufacturing engineering world wide, serving to our clients to make developments of their skill to fabricate their merchandise precisely and effectively.”

Regulation and regulatory information from Sigma Additive Options, and Nano Dimension

Sigma Additive Options is ready to conduct a 1-for-20 reverse inventory break up of its excellent widespread inventory to fulfill the Nasdaq Itemizing Rule 5550(a)(2) requirement of a minimal $1.00 bid worth per share earlier than the October 8, 2023 deadline. This transfer is predicted to facilitate the acquisition of NextTrip Holdings, Inc. and the sale of sure high quality assurance software program belongings, as indicated in non-binding letters of intent. Following the break up, the corporate’s widespread inventory will proceed buying and selling on the Nasdaq Capital Market below the image “SASI” with a brand new CUSIP quantity. The reverse inventory break up is not going to change stockholders’ proportion possession however will scale back excellent shares from roughly 12,227,135 to about 611,357 shares, plus any fractional shares exchanged for complete shares. All different monetary devices tied to the inventory can be adjusted accordingly.

Israeli electronics 3D printer producer Nano Dimension has filed a patent utility for using massive language fashions (LLM) in analyzing information produced by industrial machines. This utility, named “Giant Language Fashions for the Log File Evaluation of Industrial Machines,” is geared toward enabling real-time information evaluation and scalable implementation in Nano Dimension’s methods and options for exterior clients. The patent focuses on analyzing “log information alpha-numeric streams,” which pertain to industrial course of operation and parameters, typically involving quite a few parallel subsystems. This know-how, developed by Nano Dimension’s in-house AI group DeepCube, brings ChatGPT-like capabilities to analyzing in depth log streams with real-time, cost-effective scalability.

Catalysis expands into Europe with 3D printed tooling license

US-based 3D printed tooling options supplier Catalysis Additive Tooling, has granted a license for its novel 3D printed tooling know-how to innoMold, a revered firm close to Düsseldorf, Germany. Working as “Catalysis Additive Tooling GmbH,” innoMold will leverage this superior know-how to fabricate instruments, starting operations in October 2023. This know-how, utilized in thermoforming, seat foam manufacturing, and jigs and fixtures, allows world clients to considerably scale back tooling prices and manufacturing time, leading to sooner product launches and decreased price per unit.

Darrell Stafford, President/CEO of Catalysis Additive Tooling, expressed his enthusiasm, stated, “I’m thrilled to announce the licensing of our 3D printed tooling know-how in Europe. The outstanding firm tradition and willpower exhibited by innoMold make them a super associate for Catalysis as we purpose to strengthen our world management place in 3D tooling functions.”

A stroll down UpNano’s 5-year journey

Vienna-based two-photon polymerization (2PP) specialist UpNano is marking its fifth anniversary as a pioneer in high-resolution 2PP 3D printing. Based in 2018, UpNano has made vital strides within the world 3D printer market, introducing improvements just like the tilt-frame mechanism, superior bio inks, and software program upgrades to reinforce printing speeds. The NanoOne 3D printer lineup has garnered exponential gross sales progress, attracting consideration from academia and business alike, with MIT.nano partnering with UpNano to showcase the know-how in america. With a concentrate on precision and velocity, UpNano continues to advance 2PP 3D printing, making it a contender in serial manufacturing functions.

Bernhard Küenburg, CEO of UpNano, stated, “When UpNano was based in 2018, the panorama of high-resolution 3D-printers was disappointingly sparse. This shortage spurred us to beat the constraints of current methods. Only a yr later, we launched a considerably stronger laser system coupled with a patented adaptive decision know-how. The outcome was the NanoOne printer collection, able to high-resolution 3D-printing throughout an astounding twelve orders of magnitude.”

3D printing functions from Balena, and GREENFILL3D

Materials science firm Balena has partnered with designer Kitty Shukman to create the “ROOTS” 3D printed slide. Using Balena’s BioCir, a completely compostable elastomer, Shukman’s design integrates roots and stems into the slide’s construction. This collaboration exemplifies the fusion of vogue, know-how, and environmental accountability, paving the best way for eco-conscious design. The distinct left and proper sneakers symbolize natural progress. Balena seeks to revolutionize vogue’s sustainability with 3D printing and superior supplies like BioCir. This enterprise highlights the round potential of BioCir in 3D printing and its scalable manufacturing course of, providing accountable end-of-life recycling in industrial compost amenities, and supporting a sustainable future.

“I regularly try to strike a steadiness between performance, sustainability, and magnificence, and dealing with the Balena staff to ascertain this new design has helped me think about a day when our vogue business turns into really round,” stated designer Kitty Shukman. “I hope to see 3D printing proceed to go away its mark as a singular, daring, and sustainable medium within the vogue business on its technique to changing into local weather impartial.”

Who will win the 2023 3D Printing Business Awards? Make your nominations now!

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

Featured picture exhibits 3D printed slide. Picture by way of Balena.

[ad_2]