[ad_1]

3D printing software program developer 3YOURMIND and Phillips Corp. Federal Division have been awarded a $2.5 million contract by the US Marine Corps System Command’s Superior Manufacturing Operations Cell (AMOC).

This contract is a part of an ongoing partnership to completely combine 3YOURMIND’s half identification software program with the Marine Corps System Command’s Digital Manufacturing Knowledge Vault (DMDV).

The DMDV is a centralized digital repository for the Marine Corp to retailer information and design options for manufacturing spare components utilizing 3D printing. The DMDV is crucial to the AMOC’s mission to develop its current additive manufacturing operations.

It’s claimed that the combination of 3YOURMIND’s half identification software program with the DMDV will improve warfighter efforts to approve spare components and parts for discipline use.

“Though additive manufacturing is well-known for cutting-edge improvements, I’m inspired by our work with AMOC and Phillips Corp. to allow the Marine Corps. to make use of additive to handle extra widespread know-how and spare components gaps,” commented William Cuervo, 3YOURMIND Vice President of Gross sales, North America.

“I’m very excited for the chance for 3YOURMIND and Phillips Corp. Federal Division to complement the standard of lifetime of the warfighter by addressing these functionality gaps and contribute to the operational readiness that the U.S. Marine Corps prides itself on,” Cuervo added.

Finally, this collaboration contributes to a broader mission by the US Division of Protection to reshore provide chains, set up distributed manufacturing networks, and maintain legacy gear utilizing 3D printing applied sciences.

An ongoing partnership to safe provide chains

This newest $2.5 million AMOC award follows the completion of a first-year contract with Phillps Corp. Federal Division and 3YOURMIND.

The primary yr of this partnership noticed various key operational milestones. As an illustration, 3YOURMIND’s half identification software program was validated by screening over 10,000 components. The software program additionally demonstrated connectivity to different software program programs utilized by the DMDV.

A specialised algorithm was custom-developed for the mission specializing in 12 key influence components, which point out the printability and created worth of 3D printing per part. The primary 50,000 components have been analyzed primarily based on precedence and printability. 50 of those components have been in the end recognized as providing not less than a possible 1000 days of lead time financial savings per part.

The second yr of the initiative will look to construct on these milestones, and additional develop 3YOURMIND software program with proprietary and third-party programs, corresponding to PTC Windchill, utilized by DMDV. AMOC can even look to onboard 2D drawing evaluation capabilities, to rapidly bulk analyze technical information packages for additive manufacturing use circumstances.

This AMOC funding provides to 3YOURMIND and Philip Corp. Federal Divisions current partnership with the US Naval Info Warfare middle (NIWC) Pacific. Confirmed in July 2021, this ongoing collaboration sees the 2 firms present technical experience in software program and {hardware} to develop an optimized digital manufacturing workflow for distributed manufacturing. Because of this partnership, AMOC has additionally gained entry to 3YOURMIND’s order and manufacturing administration software program capabilities.

The growth of additive manufacturing within the US navy

This most up-to-date contract varieties a part of the US navy’s ongoing efforts to reshore provide chains, set up distributed manufacturing networks, and maintain legacy gear by means of additive manufacturing.

Earlier this yr, it was introduced that Amentum, a authorities and industrial providers contractor, had been awarded a $4.6 billion indefinite-delivery/indefinite-quantity (IDIQ) contract by the US Air Power (USAF) Safety Help and Cooperation Directorate.

This Elements and Repairs Ordering System VI (PROS VI) contract will see the corporate present “industrial shopping for options” for Overseas Navy Gross sales (FMS) clients. Via this partnership, Amentum will leverage its 3D scanning and additive manufacturing programs to modernize logistics programs, fight obsolescence, and ship value efficiencies to 105 overseas companion firms.

In January, the US Navy introduced that it had adopted Phillips Additive Hybrid steel 3D printing know-how. This 3D printing know-how, which was developed by Meltio and Haas, was put in onto the usBataan. In line with Rear Adm. Brendan McLane, the Commander of Naval Floor Power Atlantic, 3D printing know-how “helps readiness and self-sufficiency,” aboard US Navy ships. It’s hoped that this additive know-how will lower provide chain timeframes.

Subscribe to the 3D Printing Trade e-newsletter to make sure you sustain with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

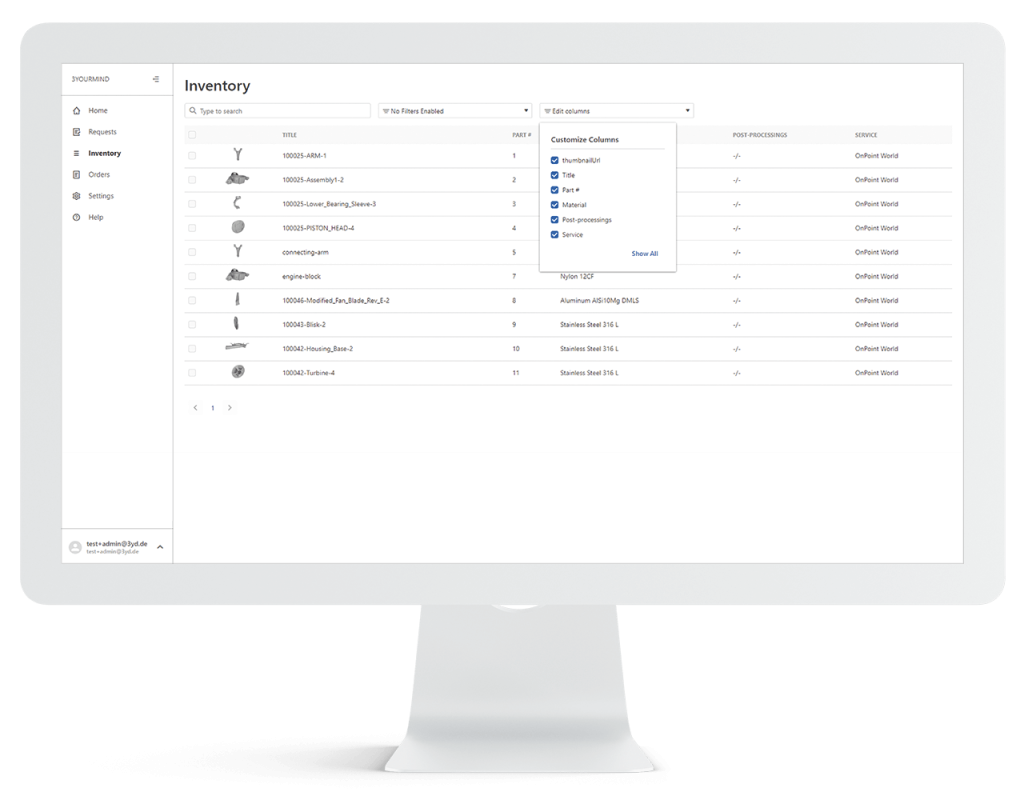

Featured picture exhibits a use case screening throughout the 3YOURMIND workflow. Picture through 3YOURMIND.

[ad_2]