[ad_1]

Decreasing emissions and optimizing assets in semiconductor manufacturing is an immensely advanced enterprise, with a number of shifting elements and several other cascading impacts. Whereas semiconductors are key to enabling a sustainable future, fabricating these chips is a notoriously resource-intensive course of. Contemplate: a single fabrication plant can devour as much as 10 million gallons of water a day, as a lot electrical energy as what’s wanted to energy 50,000 properties day by day, and, over the course of a 12 months, generate 60,000 tons of waste.

An industry-wide consensus has emerged across the significance of driving sustainable practices into semiconductor manufacturing, particularly because the {industry} is poised for additional development within the years forward. Furthermore, particular person firms are stepping as much as do their half. As outlined in our most up-to-date Sustainability Report, Utilized Supplies has made important progress in decreasing our carbon footprint and powering our operations more and more with renewable vitality. Different {industry} gamers are taking comparable actions to scale back their Scope 1 and Scope 2 emissions (these produced by an organization and the vitality it consumes).

But, as an {industry} we have to take these efforts to the subsequent stage. Decarbonization requires a concerted and collective effort to scale back Scope 3 emissions – these generated throughout an organization’s total worth chain. And that is the place issues get difficult as a result of it entails working with {industry} companions, suppliers, and prospects to outline ranges and sources of emissions being generated past the management of any particular person entity. The problem then turns into certainly one of defining the actions which are almost definitely to have a significant and measurable affect.

Excessive Worth Drawback

The stakes concerned couldn’t be greater. Advancing decarbonization is important to the way forward for the semiconductor {industry} and, in the end, to the way forward for the planet. Certainly, in programs engineering phrases, it’s maybe probably the most important high-value downside you possibly can think about.

The excellent news is we’re programs engineers. In our {industry}, we apply our expertise, abilities, and methodologies to gas unprecedented advances and innovation in semiconductor capabilities. These similar qualities are wanted to untangle the multi-layered complexities concerned in making a extra sustainable {industry}. Particularly, a programs engineering mindset can outline the cause-and-effect linkages that tie short-term actions to long-term collective objectives. These linkages present the inspiration for the important process of monitoring progress over time and holding particular person stakeholders accountable all through the journey.

Outlined listed here are three precedence areas the place – individually as firms, and collectively as an {industry} – programs engineering practices can transfer the decarbonization needle in the best path.

1. Extra Environment friendly Merchandise and Manufacturing Processes

Decarbonization begins with every firm decreasing environmental affect via extra environment friendly processes and better reliance on clear sources of vitality. However this goes past every firm merely taking accountability for its personal footprint. Particularly, the upstream and downstream results of manufacturing practices should be thought-about.

When calculating an organization’s Scope 3 emissions, the Greenhouse Fuel (GHG) Protocol contains the lifetime emissions generated by means of merchandise by finish customers. In Utilized’s case, these are the emissions that end result from the vitality and chemical substances required to energy our tools at prospects’ fabs over the total product lifespan.

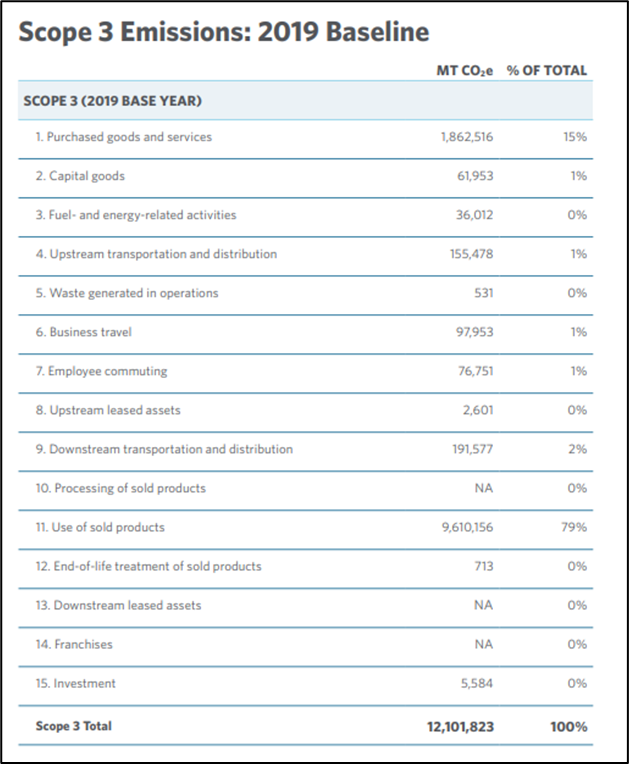

Utilized’s evaluation of Scope 3 emissions illustrates the affect of product utilization – and the extent to which we’re all on this collectively. Primarily based on our 2019 baseline, we estimate that Use of Bought Merchandise (Class 11 within the GHG Protocol) accounts for about 80 p.c of Utilized’s whole Scope 3 affect for our semiconductor merchandise (see chart beneath). As such, we’ve a robust mutual curiosity in bettering our personal practices, in addition to working with our prospects to assist them enhance theirs. Put merely, “not my downside” is just not an choice.

Among the many 15 classes outlined by the GHG Protocol, Class 11 – Use of Bought Merchandise, represents by far the biggest share of Utilized’s Scope 3 emissions. This class denotes the mixed whole emissions from all Utilized semiconductor merchandise offered throughout a reporting 12 months (together with emissions from each the expertise’s vitality attract buyer fabs and the chemical substances and gases utilized in operational processes), estimated over the common lifetime of these merchandise.

In the meantime, a collaborative method – significantly the place programs engineers are concerned – can have a significant affect. Utilized’s iSystem™ platform leverages clever Web of Issues (IoT) capabilities to reinforce vitality effectivity with out impacting manufacturing output, and has helped enhance efficiencies, scale back emissions and decrease vitality consumption for chipmakers akin to TSMC. The platform’s “energy-saving mode” allows demand-based consumption of electrical energy by synchronizing vitality must operation.

2. Grid Decarbonization

Revolutionary expertise options enabling extra environment friendly manufacturing processes and practices that scale back vitality consumption handle the demand aspect of the equation on the fab. Nonetheless, even probably the most energy-efficient fabs will nonetheless require large quantities of electrical energy. As such, grid decarbonization is important to important and sustainable emissions discount.

As an {industry}, we have to put money into scaling renewable types of vitality akin to wind and photo voltaic, and consider different carbon-free vitality sources and storage strategies. Advocacy, in the meantime, must concentrate on smarter practices – akin to guaranteeing that new fabrication services are situated in areas equipped by greater quantities of renewable vitality and that may accommodate calls for for large quantities of water. In figuring out the situation of recent fabs, a programs engineering perspective should be included in selections historically made by financial growth authorities and politicians.

3. Improve Provider Practices

Methods engineering experience will also be utilized to reinforce provider practices. The chance is important, as Bought Items and Providers (Class 1) characterize about 15 p.c of Utilized’s estimated Scope 3 emissions and are the second largest contributor to our footprint.

Right here, engineers will help procurement groups outline emissions-focused metrics and standards used to pick out and consider suppliers. Contractual clauses that present monetary incentives for suppliers to put money into new applied sciences or to develop new processes that scale back emissions could be a highly effective instrument to prioritize sustainable practices. Engineers have the information wanted to establish the areas that, for suppliers, are most tasty from a enterprise standpoint, and that can have probably the most important environmental affect.

For instance, IoT initiatives that leverage sensible sensors and networks of linked units can monitor vitality necessities, optimize consumption, and doc financial savings. As well as, such options frequently acquire and analyze information to yield new insights that may inform ongoing enhancements. Right here once more, an engineering perspective can be sure that initiatives discover the candy spot that enhances enterprise outcomes in addition to achieves sustainability objectives.

Methods engineering pondering can construct the inspiration wanted to outline priorities, develop progressive options that drive measurable positive factors and construct momentum for continued progress. Cooperation is important – our firm is only one part of a posh ecosystem, the place unbiased actions are inherently restricted. Prospects for cooperation, in the meantime, are vibrant. One current instance of that is the SEMI Local weather Consortium or SCC – a bunch of semiconductor tools producers and chip makers targeted on decarbonizing our {industry}. Utilized is a proud SCC founding member.

The thought of the semiconductor {industry} collaborating to speed up its transformation to a decrease carbon future may be very thrilling. It would absolutely take a look at our programs engineering expertise to the restrict, however the advantages for society will probably be greater than definitely worth the effort.

[ad_2]