![[INTERVIEW] Nexa3D, Wilson, and 3D printing inside the client items trade [INTERVIEW] Nexa3D, Wilson, and 3D printing inside the client items trade](https://bestnology.com/wp-content/uploads/2023/06/The-large-build-volumes-of-Nexa3D-printers-support-the-printing-of-large-molds-and-mold-inserts.-Photo-via-Nexa3D-scaled.jpg)

[ad_1]

US based mostly sporting gear producer Wilson Sporting Items are leveraging 3D printing expertise from Nexa3D, a high-speed resin 3D printer producer.

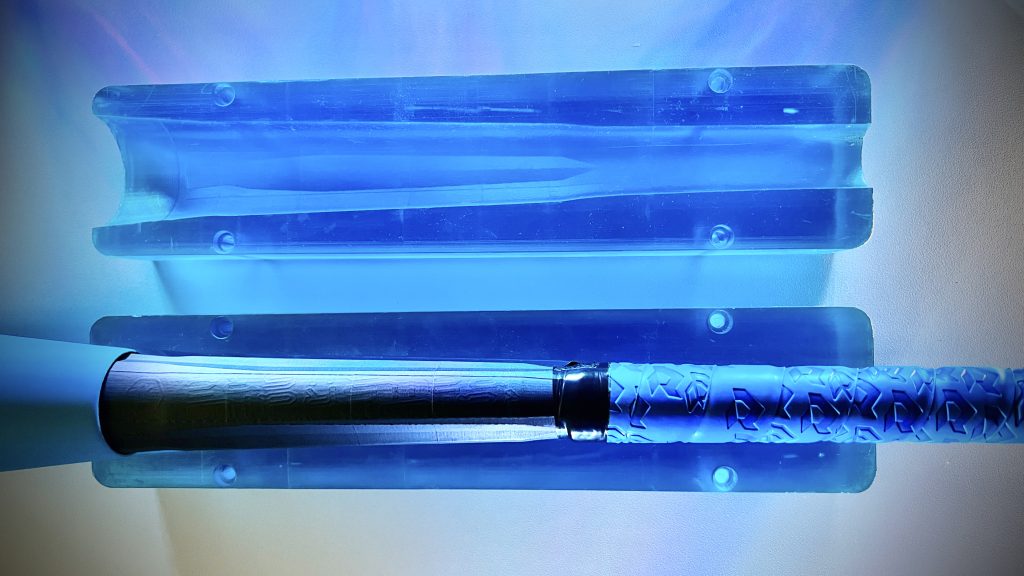

Nexa3D’s NXE400 printers are being utilized in mixture with Addifab’s freeform injection molding (FIM) expertise and xMOLD soluble resin, to prototype injection mildew tooling for Wilson’s youth baseball bat grips. Nexa3D acquired Addifab in March of this yr.

This collaboration between Nexa and Wilson is claimed to supply elevated design freedom, substantial time financial savings, and larger R&D flexibility.

3D Printing Business not too long ago spoke with Lasse Staal, Director of Enterprise Growth at Nexa3D, and Wilson’s Director of Superior Manufacturing Glen Mason, to study extra about this mission, and the function 3D printing performs inside the client items trade.

3D printing and Wilson’s workflow

Incorporating Nexa’s 3D printing expertise into Wilson’s prototyping workflow has considerably streamlined the R&D course of.

“Historically, now we have a subtractive mannequin. We design, design for manufacture, do the tooling design, lower tooling, after which ultimately mildew elements,” explains Mason. “On this case, we’re working from the half design and we are able to bypass the design for manufacturing and mildew design steps.”

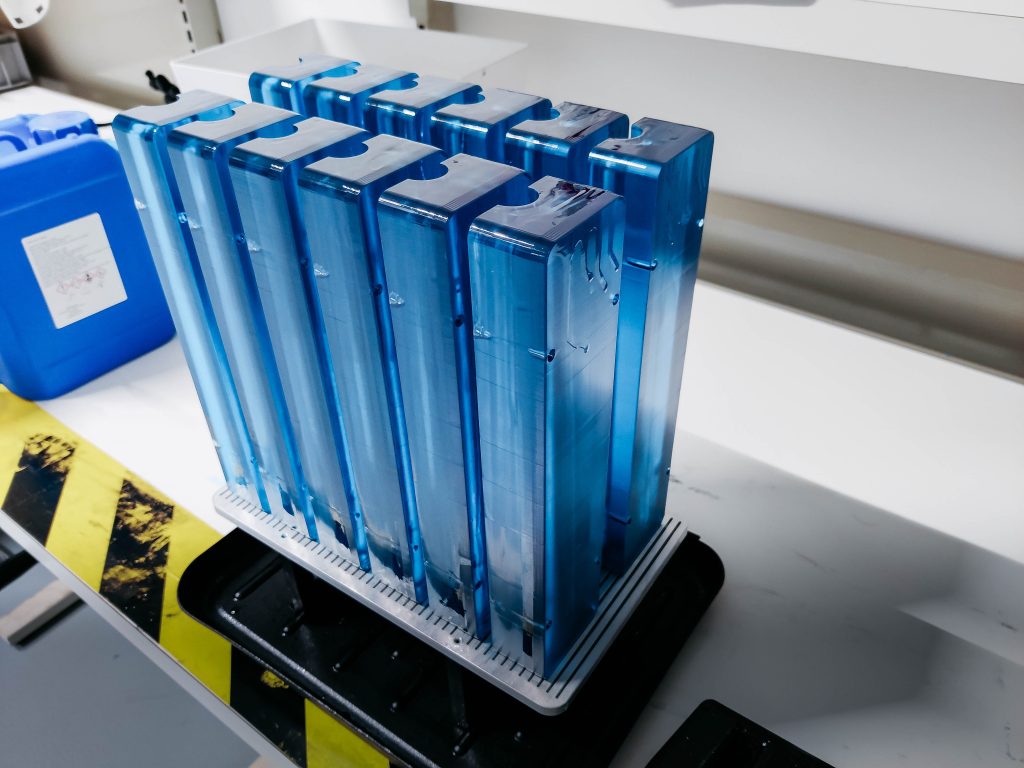

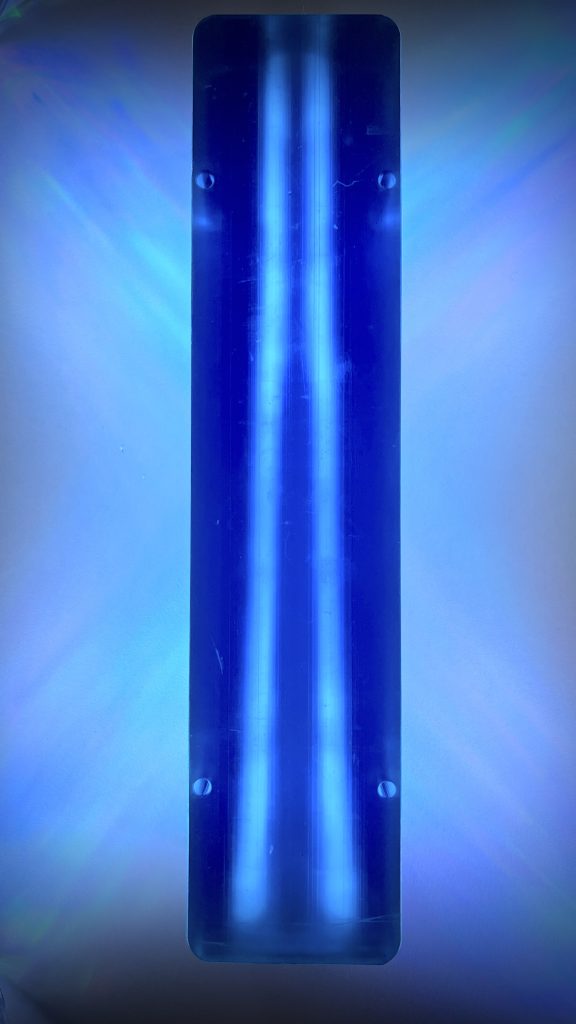

As soon as the prototype half has been designed, the mildew is 3D printed utilizing Nexa3D’s Lubricant Sublayer Picture-curing (LSPc) course of. Right here, a number of prototype instruments may be produced in a single 3D print, with one instance take a look at run collectively 3D printing 6 totally different molds (12 items) in 9 hours. The half is then injection molded, adopted by post-processing utilizing Addifabs curing system and dissolvable resin.

The advantages of additive manufacturing

3D Printing affords substantial time financial savings inside the prototyping course of, because of the velocity and amount at which the molds may be 3D printed.

“It’s a a lot sooner, a lot less complicated option to get to half,” feedback Mason. Certainly, Mason claims that “conservatively we’d see at the least a 6x enchancment between the time it takes to get a prototype in a standard world, and the time it takes to get a prototype in an additive world.”

Moreover, the direct price financial savings are additionally notable, with “the uncooked materials and labor inputs happening in an order of magnitude of 10.” In line with Mason, an element that will have price $4,000 or $5,000 beforehand, can now be additively manufactured for $500.

These advantages are key to permitting Wilson to check extra concepts, with out worrying about the fee implications of a failed iteration. When utilizing conventional manufacturing strategies, Mason explains how the corporate would typically commit a “great quantity of sources, and if we’re improper it’s actually costly to alter.”

3D printing permits Wilson to “fail quick and study sooner”, in response to Staal. “Within the financial system of immediately, that studying is known as a key foreign money as a result of should you study sooner than your competitors, you get forward by an element of many.”

Finally, 3D printing removes the restrictions which might have historically prevented a variety of initiatives from getting off the bottom.

“Whenever you take a look at all of the initiatives globally, what that is actually doing is enabling folks to do issues that will not occur in some other world as a result of there simply isn’t sufficient capability. It’s arduous to place a worth on that” states Mason. Mason views 3D printing as an “enabling expertise greater than a value discount expertise.”

Scaling and the prototyping course of

Mason highlights that this course of for 3D printing tooling shouldn’t be scalable within the conventional sense of mass manufacturing. “I don’t visualize a situation the place we’re making 1000s of elements utilizing this expertise.” That is primarily resulting from uncooked materials prices related to this technique of tooling.

Nonetheless, in the case of the “data a part of the puzzle,” Mason sees nice scaling potential. That is related much less with the prototype half itself, and extra with the method for 3D printing these prototypes. “What this expertise permits me to do is create a prototype half and on the similar time, create a prototype course of,” explains Mason. “So I’m creating the half in the identical course of that I’d go to scale with.”

Equally, Staal claims that the idea of scalability takes on a barely totally different which means when contemplating injection molding tooling. While typical injection molding is sort of binary in nature, Staal factors to 3D printing as offering the chance “to maneuver into scale at a tempo that may be a little much less of a leap of religion,” and in the end attaining the “proper stage of productiveness for every step of your product lifecycle on the lowest doable prices.”

In relation to 3D printing and client items extra typically, each Mason and Staal view mass customization as being key. Staal highlights the customized listening to assist and dental aligner industries as incorporating additive manufacturing to realize million half manufacturing runs. Staal states that hundreds of thousands of listening to assist shells are produced a yr, with tens of 1000’s of 3D printers operating in parallel.

Staal additionally highlights Nexa3D’s vast materials compatibility as scaling excessive quantity manufacturing runs. “You want to have the ability to make as many issues as doable with one manufacturing setup,” claims Staal. With over 30 appropriate supplies, Nexa3D additionally affords an open supplies program, which permits for using non-Nexa3D developed materials.

Consequently, on any given day, Nexa3D 3D printers can take part in a number of totally different manufacturing runs and totally different manufacturing traces. “As a substitute of getting one machine doing one particular job all day lengthy, one machine can contribute to the manufacturing of lots of totally different merchandise,” providing vital potential for scalability, Staal claims.

The way forward for 3D printing for client items

What’s subsequent for additive manufacturing and the patron merchandise trade?

Mason argues that there are nonetheless a variety of challenges 3D printing wants to beat earlier than the expertise strikes past prototyping, and we see mass-produced 3D printed elements within the client’s arms.

“There’s challenges round printing elements from a fabric standpoint, from a floor end standpoint, and even one thing as trivial as coloration is difficult.” The truth that additive manufacturing primarily produces mono-material objects is one thing which Mason views as limiting development of 3D printing inside this trade. “Till we are able to get a number of supplies interacting on the similar time, I don’t foresee 3D printing fixing any client initiatives,” claims Mason.

Mason does envisage vital developments in velocity and 3D print measurement. Nonetheless, inside the client items sector, 3D printing appears set to go with legacy applied sciences corresponding to injection molding, reasonably than superseding them.

Subscribe to the 3D Printing Business e-newsletter to make sure you sustain with the newest 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture reveals Nexa3D 3D printed mildew inserts. Picture by way of Nexa3D.

[ad_2]