[ad_1]

On the subject of 3D printing in aerospace, metals are sometimes the traditional materials. Nevertheless, high-performance 3D printed ceramics possess a lot of glorious properties which make them extremely environment friendly, and particularly effectively suited to use in excessive environments. This makes ceramics superb for 3D printing components for aerospace functions.

On this article, we discover the numerous potential supplied by ceramics, and the way Lithoz’s LCM know-how is altering the sport for 3D printing and aerospace.

The spectacular properties of ceramics

At the moment, the widespread use of metals signifies that ceramics are not often on the prime of an engineer’s buying record. Nevertheless, the truth that metals rapidly attain their pure limits below harsh circumstances signifies that ceramics are gaining ever extra prominence.

However what makes ceramics so effectively suited to harsh and intensely demanding environments?

Excessive-performance ceramics possess extremely excessive hardness, abrasion and warmth resistance, and are immune to sizzling corrosion and oxidation. Moreover, components 3D printed with ceramic provide mechanical and dimensional stability, while sustaining mechanical energy at extremely excessive temperatures. Ceramics even have {an electrical} and thermal insulation impact, including to their utility for inner mechanical elements.

Mix these glorious properties with the design flexibility of 3D printing, and you’ll discover a very new dimension of aerospace functions.

3D printing ceramics for aerospace functions

It’s extensively recognized that additive manufacturing can produce components which might be extra sturdy and sophisticated than something at present doable by means of standard manufacturing strategies. Furthermore, when manufacturing elements for house and aviation functions, it’s important that the chosen materials will face up to even essentially the most excessive thermal circumstances. Due to this fact, 3D printing with ceramics gives the right mixture for producing components which might be each extremely advanced and subsequently extra environment friendly, able to performing in harsh and demanding environments.

Certainly, engineers are at all times looking for methods to extend effectivity, scale back consumption, restrict waste, enhance cooling, and obtain longer uptime. Combining the design freedom of 3D printing with the sturdiness of ceramics gives the best resolution for this.

One key profit supplied by this mix is the discount of house particles. Due to their sturdiness, ceramic components can be utilized the place even the hardest metals fail. Inside an aerospace context, metals possess a shorter lifespan than ceramics, and can fail sooner when uncovered to excessive thermal circumstances. These failed components turn out to be house particles. Utilizing ceramics reduces house particles as careworn components present much less put on below these excessive circumstances.

Moreover, 3D printing with ceramics permits for the manufacturing of extremely exact and complex components. Inside spacecraft, components starting from thrusters and sensors, to advanced aviation casting cores with intricate channels, require an unbelievable excessive stage of precision and accuracy.

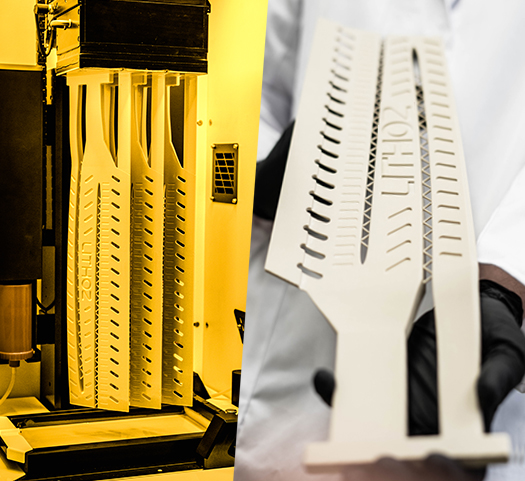

Inside aviation, stricter emission laws require ever extra advanced cooling channels in turbine blades to realize higher effectivity by extra refined cooling. The normal funding casting methodology just isn’t capable of produce such superb constructions. 3D printed ceramic casting cores enable for a lot better design freedom, larger half complexity and finally the specified improved cooling impact.

Lithoz and ceramic 3D printing

Lithoz, a number one developer of commercial ceramic 3D printers, has already efficiently accessed the potential supplied by ceramic 3D printing for aerospace functions. Lithoz’s CeraFab S65 industrial printer with Lithography-based Ceramic Manufacturing (LCM) know-how gives extremely exact 3D printing with precise repeatability in serial manufacturing.

One extremely in-demand high quality of Lithoz’s LCM know-how is the flexibility to 3D print ceramic casting cores for plane turbine blades. As already talked about, 3D printed ceramic casting cores are essential for producing advanced turbine blade cooling channels. The pace and quantity at which Lithoz’s 3D printers can produce these components drastically reduces growth time, rushing up time-to-market.

Superb for manufacturing advanced and exact ceramic components, Lithoz’s CeraFab Multi 2M30 LCM 3D printer additionally gives multi-material capabilities. This 3D printer can mix completely different ceramics with metals or polymers, permitting for groundbreaking multi-functional components with a mix of many fascinating materials properties in a single half. Lithoz’s new two-vat system permits these completely different supplies blended layer by layer and even flexibly graded in the identical layer throughout the identical print job.

As an example, this two-vat system permits for tailor-made porosity to be achieved. Lithoz’s multi-material LCM 3D printers can overcome the principle issues of standard manufacturing methods for fabrication of porosity graded alumina, with desired microstructure and gradient structure. That is superb for R&D functions for ion thrusters.

Lithoz’s LCM course of combines the specified aerospace properties with the in any other case unachievable flexibility of 3D-printed designs. This ends in the manufacturing of totally dense components with unmatched element and precision.

Because of this, components could be 3D printed which might be stronger and possess an extended lifespan than metallic, leading to much less house particles and fewer downtime. What’s extra, these ceramic elements also can incorporate advanced designs beforehand unthinkable when utilizing standard manufacturing strategies.

Lithoz have additionally scaled up their know-how to the extent of commercial serial manufacturing. Due to this fact, along with the technical and materials benefits supplied by LCM, manufacturing could be ramped as much as serial stage for 3D printing high-quality components at quantity.

One good instance of how LCM ceramic 3D printing will change the extent of effectivity in aerospace functions are ceramic RF filters. Such filters are digital circuits which play an important position in enhancing sign high quality and minimizing interference in communication programs. Ceramic 3D printing with LCM know-how permits for the mandatory advanced and exact shapes of those filters to be systematically produced in a miniaturized format. This shrinkage of your entire software permits for a major weight discount, the primary goal of aerospace engineers.

A key good thing about utilizing ceramics with a excessive dielectric fixed and low loss issue is the truth that the upper the dielectric fixed (at a secure loss issue) is, the smaller the filter could be designed. Due to this fact, these ceramics are perfect for LCM know-how that gives unmatched precision, and which is optimized for 3D printing miniaturized components.

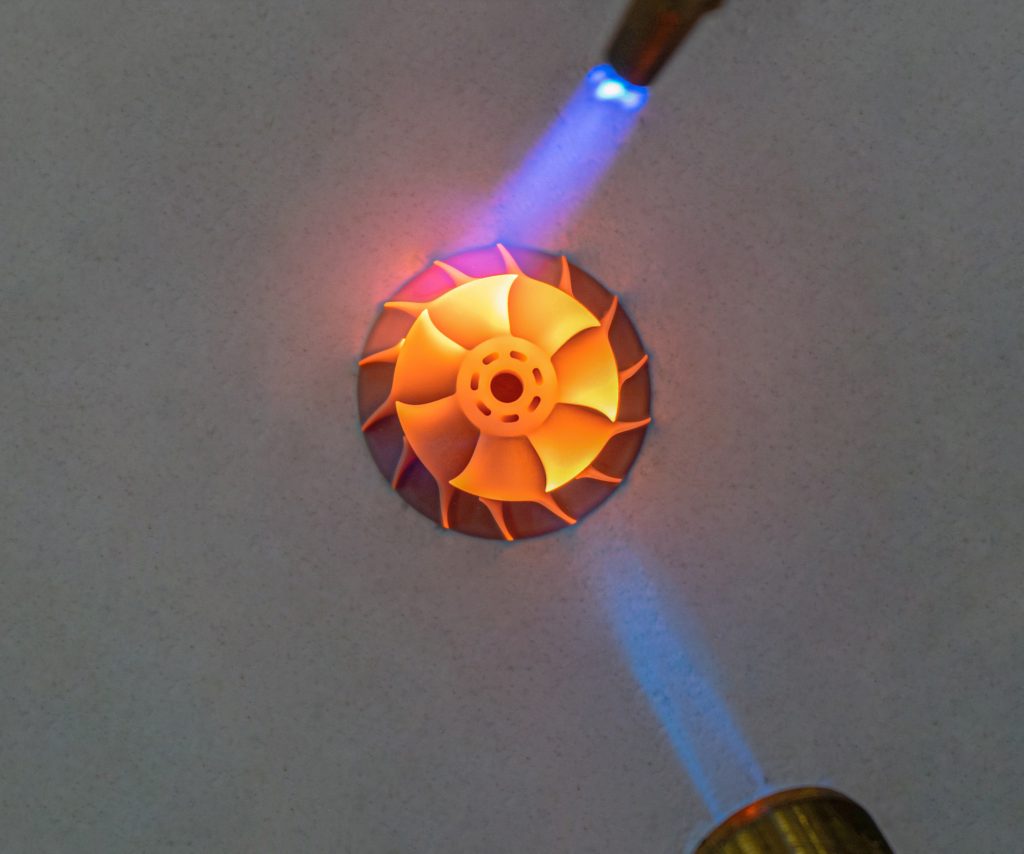

Silicon nitride aerospike nozzles may also be 3D printed with Lithoz LCM know-how, with Lithoz’s LithaNit materials superb for such functions. As a consequence of their excessive energy, alkali and acid resistance, and particularly its superior thermal shock resistance, these darkish ceramics are good for aerospace elements. Silicon nitride is right for 3D printing insulators, springs and turbine wheels.

Subscribe to the 3D Printing Trade publication to make sure you sustain with the newest 3D printing information. It’s also possible to observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture exhibits a fired silicon nitride nozzle. Photograph through Lithoz.

[ad_2]