[ad_1]

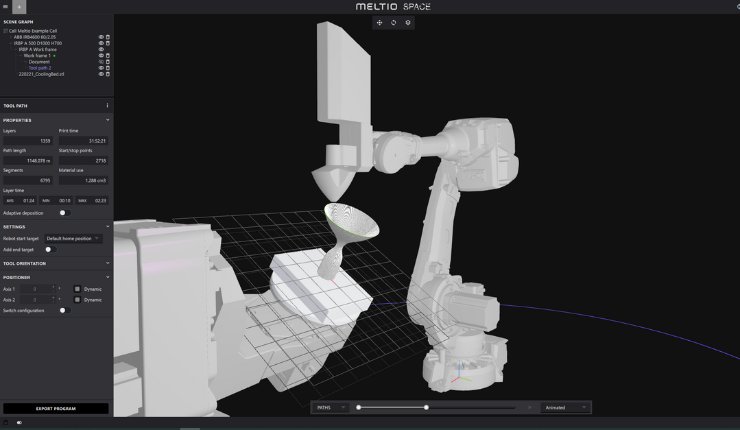

Meltio has introduced what it says is a ‘big leap’ in direction of facilitating using its wire-laser metallic 3D printing options, the Meltio Area software program. Meltio Area is a toolpath generator software program for the Meltio Engine Robotic Integration with an ‘easy-to-use’ interface for planar, non-planar, and variable extrusion toolpaths.

The software program additionally consists of 2-axis workpiece positioner interpolation, kinematics simulation, collisions examine, and cell configuration.

The Spanish firm says thew new slicer is an ‘revolutionary’ addition to its product lineup, providing a ‘new perspective’ on 3D printing by transferring away from conventional 3-axis programs. The corporate says the software program expands on the probabilities of its 3D printing know-how by incorporating superior robotic manipulation capabilities.

Meltio says the software program is particularly developed to speed up the adoption of its 3D printing and ‘revolutionises’ the sphere of robotic AM. The corporate says that customers can shortly adapt to and leverage the advantages of robotic additive manufacturing with out requiring experience in robotics or programming.

Meltio says that with the combination of the 6-axis robotic manipulator and 2-axis workpiece positioners, it opens up a ‘complete new realm’ of prospects for metallic 3D printing.

Meltio Engine Product Supervisor Alejandro Nieto stated: “Meltio Area makes it potential to design very dependable components as shortly as potential with a wider vary of prospects for our industrial clients. And that is because of a really user-friendly interface of the Meltio Engine Robotic Integration. Meltio Area additionally consists of preset and beneficial materials profiles and 3D printing parameters and a collection of particular processors for robotic arms from ABB, Kuka, Fanuc, and Yaskawa together with collision detection, and simulation.

“The principle aim of our know-how is to offer essentially the most environment friendly instrument that enables the trade the a lot of the purposes they should manufacture metallic components with our wire-laser know-how. Meltio Area is a residing platform that can present suggestions to maintain bettering and provides aggressive software program to totally different industrial clients of Meltio.”

Meltio Area employs a digital mannequin of the actual robotic motion, a characteristic which permits customers to simulate the kinematics of the robotic. Meltio says this ensures correct and exact 3D printing. The slicer additionally performs collision checks with the half being printed, minimising the chance of errors or injury through the 3D printing course of.

Learn extra:

IRTI Robotics introduced as gross sales accomplice for Meltio within the Indian 3D printing market

Siemens expands 3D printing initiatives in the US with Meltio robotics

[ad_2]