[ad_1]

Reporting from AM Discussion board Berlin 2023, we noticed how 3D printing is used within the provide chain within the automotive, mobility, and protection sectors.

This text offers insights into the railway business provide chain from Siemens Mobility and SNCF. Plus, the query of the effectiveness of utilizing 3D printing to unravel provide chain challenges is addressed by Stratasys and CTC, an Airbus firm.

The 3D Printing Trade Awards are again – nominate now.

How the railway business is utilizing 3D printing within the provide chain

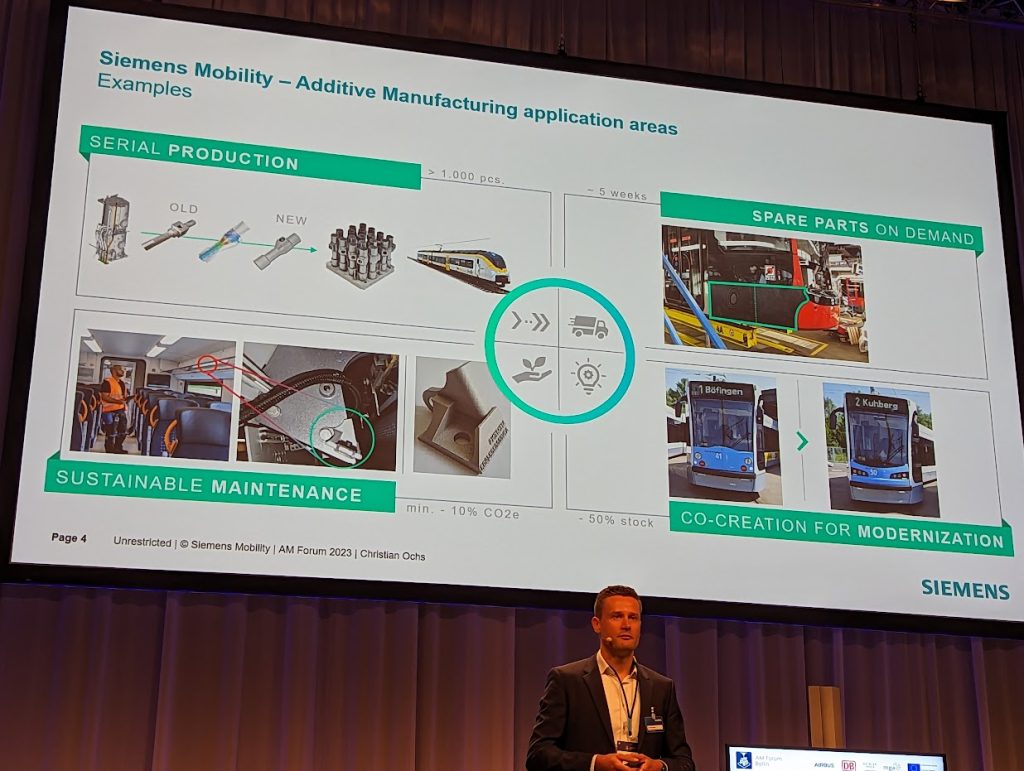

Christian Ochs, the Head of Additive Manufacturing at Siemens Mobility GmbH, describes the weather that make the railway business an fascinating case examine for 3D printing, “You even have very refined requirements and norms. And you’ve got a whole lot of regional variations between nations.”

Ochs additionally underscores the significance of supplying spare elements with reliability and on time. He raises a noteworthy level: the ever-present high-cost stress within the railway enterprise. The necessity for high-quality and cost-efficient elements in a sector with various regional norms presents a singular set of challenges for additive manufacturing. He suggests a doable resolution is collaborating with clients and authorities to fast-track the method of attaining extra economical use instances.

Ochs additionally highlighted how additive manufacturing is already modernizing railway fleets. Trains bear a complete overhaul after 16 or 18 years, usually together with the introduction of latest screens and air-con programs which might be heavier than their predecessors. 3D printed elements, he famous, may be as much as 50% lighter attributable to clever design, enabling upgrades with out vital weight will increase. This not solely saves prices but additionally avoids the time-consuming and costly strategy of acquiring new approvals.

Future fleets of autos might rely closely on the promise of lifetime availability for elements that 3D printing may provide. Nonetheless, Ochs careworn that additive manufacturing isn’t only a contingency plan for when conventional manufacturing strategies fail. “When creating our subsequent era of trains, we [ask] the place can we [introduce] additive elements? Proper from the start to actually use the design freedom,” Ochs mentioned.

The Siemens Mobility Head of Additive Manufacturing additionally revealed how his agency was altering the panorama of auto repairs with additive manufacturing.

Ochs defined, “We did an additive redesign; we segmented [the vehicle] into elements, which has the profit that only one half may be exchanged.” This methodology, he famous, was significantly helpful in case of accidents, which may occur between tramcars and autos. “We modernized it, and we did this in a co-creation along with a buyer,” he elaborated. “And the profit is inventory ranges are lowered.”

The method additionally had optimistic implications for inner operations. Siemens created a small restore unit through Selective Laser Melting (a sort of 3D printing that makes use of a high-powered laser to soften and fuse nice metallic powders), saving supplies and power. “We created a brand new smallest restore unit through selective laser melting, which now can face up to 2.5 occasions the load and introduced into the automobile advantages 95% much less materials consumption and naturally much less power consumption as nicely,” Ochs acknowledged.

Not restricted to bespoke elements, Siemens has additionally launched into serial manufacturing of 3D printed parts. “The instance here’s a nozzle which has 5 occasions the efficiency a standard half may attain and is 70% lighter,” mentioned Ochs. Up to now, Siemens has used laser powder mattress fusion to supply over 100,000 items.

Regardless of these advances, the journey to additive manufacturing of spare elements has not been with out challenges. “After all, we scan our inventories to see if there are elements that match higher to be produced additively…all these elements up to now have been designed for standard manufacturing,” Ochs famous. The prices of 3D printing can usually be greater, he warned, therefore the necessity to think about extra advantages akin to stock discount and avoidance of penalties attributable to automobile downtime.

Industrialisation of additive manufacturing at SNCF

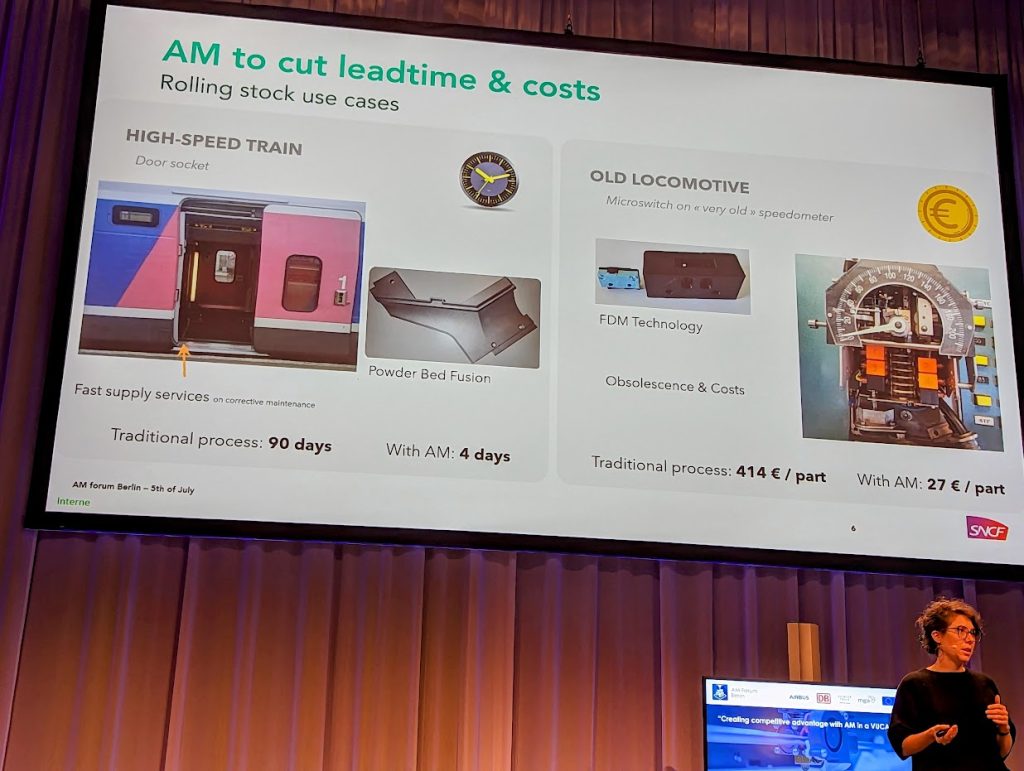

France’s nationwide state-owned railway firm, SNCF, can be taking a look at an progressive method to bettering efficiency and effectivity. Hélène Sapardanis, challenge supervisor of progressive supplies and processes at SNCF, gave an outline of the continued tasks that intention to combine 3D printing into railway operations. “We’re actually pushing for the industrialization of additive processes within the railway sector,” she defined.

The challenge Sapardanis works on is entitled ‘Additive4Rail’, largely geared toward reworking upkeep processes within the railway business. SNCF’s dedication to upkeep is demonstrated by the truth that it accounts for 30% of manufacturing price for rail service. Primarily, the main target is on the rolling inventory (locomotives, carriages, wagons, and many others.). From repairing key parts, reworking trains, upgrading and overhauling to modifying trains, the scope is immense.

With a substantial 200,000 spare elements references for infrastructure and rolling inventory, the potential for additive manufacturing is substantial. “About 10% of this may be remodeled by additive manufacturing,” Sapardanis reveals. She highlights how 3D printing may help cut back operational downtime by expediting the manufacturing of mandatory elements, even recalling a time when a lacking cap for a bathroom held up a high-speed practice.

The expertise additionally affords options to obsolescence points. For older trains the place the unique provider might not be in operation, creating the required parts turns into a problem. Right here, additive manufacturing may step in to fill the void, holding these machines in operation.

There are hurdles to be overcome for the complete integration of additive manufacturing within the railway sector. As an illustration, most of SNCF’s spare elements designs are in 2D, a format circuitously suitable with 3D printers. Moreover, from a regulatory perspective, there’s a shortage of fabric and course of knowledge from a consumer viewpoint, coupled with stringent flame retardant necessities. Additive manufacturing prices additionally stay prohibitive, significantly for bigger elements. And maybe most crucially, adopting additive manufacturing means a whole rethink of the availability chain, from engineering to buying.

SNCF and its companions intention to develop new supplies, enhance using present supplies, and cut back the price of parts. Particularly, the challenge has set a objective to broaden the flame-retardant materials portfolio within the railway sector. Presently, just one appropriate materials exists available on the market, which is dear, prompting the necessity for alternate options, in keeping with the challenge supervisor.

As Sapardanis notes, the initiative features a plan for certification proper from the challenge’s inception. It’s not an afterthought, for as she says, it’s essential to not get to the top of a challenge and surprise, “what are we going to do with this half?”

The challenge has already seen tangible outcomes, with an additive manufacturing cell at a upkeep heart in Saintes, close to Bordeaux. They’ve managed to supply elements in-house, providing a glimpse of the long run course of railway upkeep. One explicit achievement is the manufacturing of two shafts, every weighing round 60kg. Whereas the precise software continues to be to be decided, the success of this manufacturing hints on the promising potential of additive manufacturing within the railway business.

Will 3D printing clear up all provide chain points?

Does utilizing 3D printing to unravel provide chain challenges make sense for everybody? Andreas Langfeld, President EMEA at Stratasys, sees a necessity for much less hype round additive manufacturing and extra deal with present doable use instances somewhat than fantasizing about printing thousands and thousands of elements in a day. “We have to present a full workflow resolution,” Langfeld mentioned, underscoring the significance of providing not only a 3D printer but additionally software program, mandatory supplies, and certification proofs. He argued towards corporations aiming to supply a big share of elements by additive manufacturing as a place to begin. As a substitute, a single half with a fast return on funding may yield vital financial savings and open the best way for additional additive manufacturing.

Equally, Marc Fette, CEO of Composite Know-how Heart (CTC), an Airbus firm, pointed to the complexity of integrating additive manufacturing into the aerospace sector. Regardless of having “100 elements that are thermoplastic now,” Fette mentioned, “It’s a bit quantity in the meanwhile. It’s a distinct segment, and it’s not wired into manufacturing.” An important problem lies within the certification and qualification processes mandatory for supplies, strategies, and designs in industries like aerospace, just like railway and shipbuilding.

So, how you can advance? Sascha Hartig, Coordinator of Additive Manufacturing for the German Navy, revealed that there’s certainly a plan to introduce 3D printers to each navy ship. He emphasised that this wouldn’t be a one-time implementation of a number of machines however somewhat a fastidiously executed, iterative course of involving coaching crew members on utilizing these printers.

The discussions on the AM Discussion board Berlin 2023 replicate the burgeoning curiosity and potential of 3D printing throughout industries, together with the mobility sector. Whereas the expertise affords transformative options, particularly in sectors with intricate requirements and desires, its integration is difficult. Trade leaders name for a practical method, prioritizing real-world purposes, workflow options, and addressing regulatory hurdles. The journey to harness the complete potential of additive manufacturing is ongoing, with stakeholders repeatedly exploring avenues to optimize its advantages.

Inform us who’s main the business. Nominations are open for the 3D Printing Trade Awards.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter, observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

[ad_2]