[ad_1]

I attended Europe’s largest protection and safety occasion, DSEI, to listen to how the sector makes use of additive manufacturing.

“Ten-minute warning” will not be a phrase you hope to listen to at an occasion jammed to the rafters with army {hardware}, surrounded by at the very least a brigade’s value of officers from worldwide militaries, and a number of other new autos from the British Military’s £5.5 billion Ajax program. Luckily, this name was issued to wrap up a dialogue panel headed by the MTC’s Andy Barnes on Additive manufacture at level of use: Challenges and alternatives.

“Additive manufacturing began out as a speedy prototyping expertise. Over latest years, additive has moved rather more into the mainstream for brand spanking new part functions,” started Dr. Ross Trepleton, Affiliate Director – Know-how Technique at MTC. The world is shifting from viewing additive manufacturing as a prototype system to embracing it as a software for revolutionary options.

He showcased intriguing examples: a GE midframe construction that eradicated the necessity for 300 elements from 50 completely different sources and an area utility antenna that consolidated 100 elements into one, leading to a sizeable 95% financial savings. Notably, the U.S. listening to help sector demonstrated a sturdy shift, with the whole provide chain changing to additive manufacturing inside 500 days, leaving firms that didn’t shift out of enterprise.

On the subject of protection, the functions are manifold. Frontline command alternatives can use applied sciences like chilly spray or filament-based additive options for pressing short-term repairs. Dr Trepleton additional illustrated a periscope system, a product of collaboration between Babcock Worldwide Group and the MOD, which proved extra economically possible by way of additive manufacturing than conventional strategies.

A number of conversations throughout the present flooring illuminated the chance for additive as a sustainment expertise working inside MRO.

But, there are challenges. As Trepleton underscored, “So we very often hear – isn’t additive manufacturing costly?” The upfront prices may appear greater, however the decreased lead occasions and potential value financial savings in downtime typically justify the expense.

However the place does protection actually stand to realize from this?

Group Captain Leonie Boyd from the Royal Air Drive weighed in on this essential query. Emphasizing the dynamic and unpredictable challenges protection forces face – from pure disasters to geopolitical tensions just like the latest state of affairs in Ukraine – she said, “We want a extra versatile, scalable vary of options.” Additive manufacturing presents simply that, offering a supplemental avenue to conventional strategies.

Boyd’s phrases painted an image of a contemporary, agile protection pressure. One which not solely repairs but in addition innovates. “We’ve received capabilities for additive manufacturing to create instruments, bespoke or alternative instruments,” she famous, highlighting the RAF’s success in creating a prototype spare half in simply 24 hours, a activity that will have taken three or 4 days utilizing conventional strategies.

For the Navy, the imaginative and prescient is world manufacturing hubs strategically positioned to make sure effectivity. Boyd defined the idea of a hub the place information may very well be despatched for elements, with the part ready upon arrival – a revolution in logistical effectivity.

Closing her phase, Boyd encapsulated the sentiment of the session: “Additive manufacturing… will increase the choices accessible to us to take care of our gear, to extend scalability and sustainability, and finally assist us be prepared for no matter operational necessities.”

3D Printing’s Challenges and Triumphs: Navigating Unpredictable Waters

Producers are turning to 3D printing as a technique to avoid provide chain disruptions and produce elements extra quickly. Specialists within the subject unpacked the complexities and alternatives within the sector. Their insights paint a vivid image of an {industry} at a crossroads.

“Defence setting… we are able to’t forecast the whole lot on a regular basis,” stated Jonathan Morley, Programme Director – Materials Availability Companies at Babcock Worldwide Group. He elaborated on the benefits of additive manufacturing to deal with surprising gear damages and defects. It supplies a nimbleness typically lacking in conventional manufacturing fashions.

He means that with 3D printing, there’s an rising alternative to innovate, specializing in the rapid wants whereas side-stepping the bottlenecks related to bigger, conventional processes. “We’ve received to begin fascinated about the price of not beginning,” he asserted, stressing the burden of alternative prices versus manufacturing prices.

Steven Barnes, BAE Methods Air‘s Additive Manufacturing Course of & Functionality Lead, spotlighted workforce challenges. Many recruits lack particular coaching in designing for 3D printing. Whereas they is likely to be seasoned in different areas, these expertise don’t simply translate to the additive manufacturing panorama. Barnes additionally touched on the pressing want for “standardization” – the trinity of a constant materials provide, dependable processes, and information refinement.

Safety Considerations and Collaboration

The protection sector treads rigorously round categorized data, a priority that Morley addressed immediately. Whereas collaboration is “in our coronary heart,” he stated, integrating exterior companions requires navigating a maze of cybersecurity stipulations. Categorised information typically is a hurdle, particularly when integrating non-defense consultants into the fold.

Nevertheless, Morley stays optimistic, “collaboration goes to need to turn into elementary,” emphasizing the necessity to shift from remoted efforts to collective pursuits to unlock true potential.

Steven Barnes supplied a sobering reminder in regards to the complexities of mental property rights (IPR). In an {industry} the place billions are spent on expertise growth, the road between public area data and proprietary information turns into blurred.

Dr. Ross Trepleton of the Manufacturing Know-how Centre noticed a optimistic shift post-COVID. The conclusion that collaboration might yield better outcomes has led to an openness beforehand unseen within the sector.

Kieron Salter, CEO of Digital Manufacturing Centre, honed in on information integrity and safety. When a whole provide chain hinges on 3D printing, verifying the legitimacy of elements and sustaining information management turns into paramount.

3D Printing’s Transformative Arc in Defence Manufacturing

Steven Barnes from BAE Methods Air underscored the rising significance of unique gear producers (OEM) within the design course of. “Some [manufacturing parts] come from the OEM. Having these inbuilt on the design stage and certified makes it simpler… to say, please make me one other one utilizing the certified course of,” Barnes defined. This emphasizes the shift in design pondering, the place elements are more and more tailor-made for the 3D printing course of from inception. Furthermore, he touched on the potential advantages of “incentivizing” the usage of 3D printing, particularly when sure elements are regularly broken or misplaced. In essence, the clearer the rules, the extra seamless the adoption.

Dr Ross Trepleton, from the Manufacturing Know-how Centre, recognized some challenges going through the 3D printing realm. “The primary one may be very a lot round elevating consciousness,” he highlighted. Dr. Trepleton’s feedback mirror a sentiment many within the {industry} share: whereas consultants see its deserves, many organizations are unaware of the expertise’s transformative potential. Furthermore, monetary apprehensions can impede adoption. Dr Trepleton relayed the issues of SMEs: “Why would I make investments 1,000,000 within the new additive machine… after I might purchase a five-axis CNC?” This illustrates the necessity to recalibrate perceptions, putting emphasis on long-term returns fairly than rapid good points.

Kieron Salter, CEO of the Digital Manufacturing Centre (DMC), additional expounded on “designing for additive manufacturing.” It isn’t merely about adapting present designs to the 3D course of; it’s about reimagining the design. Salter shared insights from his background in motorsport, stating, “The true problem is designed for additive manufacturing… it’s not simply designed for manufacture.” The central query turns into not if an element will be 3D printed however why it ought to be. Advantages corresponding to speedy lead occasions, value efficiencies, and lightweighting are potential game-changers. Salter underscored this with an automotive case research the place DMC reworked a single prototype half into 400 production-ready additive designs.

Group Captain Leonie Boyd of the Royal Air Drive recognized one other problem: the shortage of coherence amongst protection branches relating to 3D printing. “We nonetheless don’t have a single protection technique or coverage round this,” she stated. The state of affairs illustrates not simply an operational problem however a strategic one. To actually leverage the ability of 3D printing, cohesive insurance policies, and widespread adoption are key.

Additive Manufacturing: Stepping Up the Protection

Dr. Trepleton of the MTC underscored the important want for standardized processes inside AM. “We do a number of single-part operations,” he famous, hinting on the potential for scale and effectivity ought to standardization turn into the norm. The subject of consistency and repeatability additionally gained traction, with Steven Barnes of BAE Methods emphasizing the necessity for “having measures in place to calibrate and monitor… to know deviations.”

As Barnes elucidated, “We have to have an industry-level consensus as to what an ordinary course of means.” And the {industry} could also be nearer to this aim than one would possibly assume. Vital our bodies like ASTM are already carving paths on this regard.

Jonathan Morley, Programme Director – Materials Availability Companies at Babcock Worldwide Group, lamented the prevailing state of affairs. “We’re not anticipating anybody to turn into the world’s professional,” he stated, emphasizing the necessity for simply “a familiarity and consciousness of what the world’s doing.” He paints a situation of companies falling behind and lacking the mark just because their broader group, together with industrial and finance, isn’t adequately plugged into the speedy developments in additive manufacturing. Morley astutely famous, “It’s right here now, and it’s a choke level in regards to the worth.”

In easy phrases, whereas 3D printing presents revolutionary potentialities, its complexity calls for a baseline understanding. Like all game-changing tech, the purpose isn’t to make each govt an professional however fairly to instill a primary comprehension – lest companies turn into out of date.

Steven Barnes, the Additive Manufacturing Course of & Functionality Lead at BAE Methods Air, anchored the dialog to a urgent situation: the pivotal function of design within the 3D printing ecosystem. “So many issues are pushed into the design of the part when the designer turns up on the door,” Barnes described, emphasizing the frequent inefficiencies and bottlenecks launched when parts are designed with out 3D printing in thoughts. This strains the method and underscores the essential must embed 3D printing data early within the design section.

Tasks corresponding to TAMPA – Additive Manufacturing as a Service, are underway to speed up the maturity of additive manufacturing and make higher use of it.

Dr. Ross Trepleton, Affiliate Director – Know-how Technique on the Manufacturing Know-how Centre, took the dialogue world. He highlighted how international locations just like the US are considerably forward, with initiatives corresponding to America Makes, a DoD-backed public-private partnership since 2012. These applications, he identified, are “pushed by the wants of time,” a stark distinction to the extra disparate efforts within the UK.

The undercurrent all through was clear: with out consensus on requirements and a concerted effort to construct {industry} familiarity, the UK dangers being left within the 3D printing mud.

It was clear that the promise and potential of additive manufacturing inside the protection sector stays each fascinating and difficult. The clarion name was loud: it’s time for a collaborative method, particularly with requirements, information sharing, and the digitization of the availability chain.

Learn extra from 3D Printing Trade at DSEI right here.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You may as well comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing {industry}? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

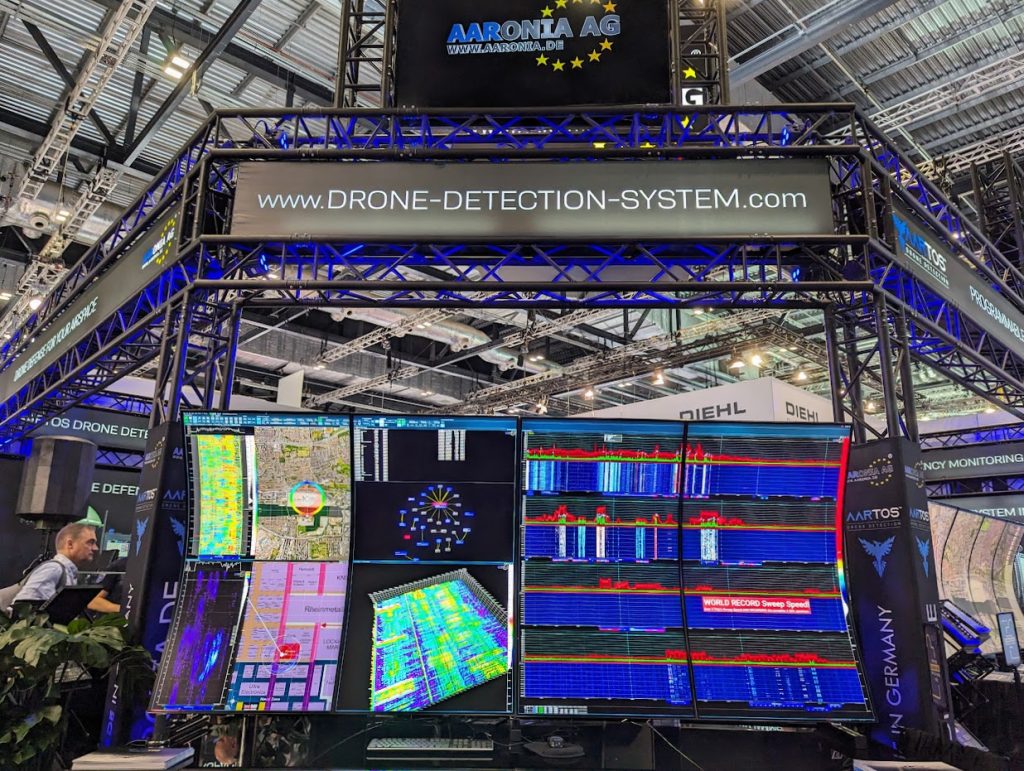

Featured photos reveals the doorway to DSEI 2023 at ExCel London. Picture by Michael Petch.

[ad_2]