[ad_1]

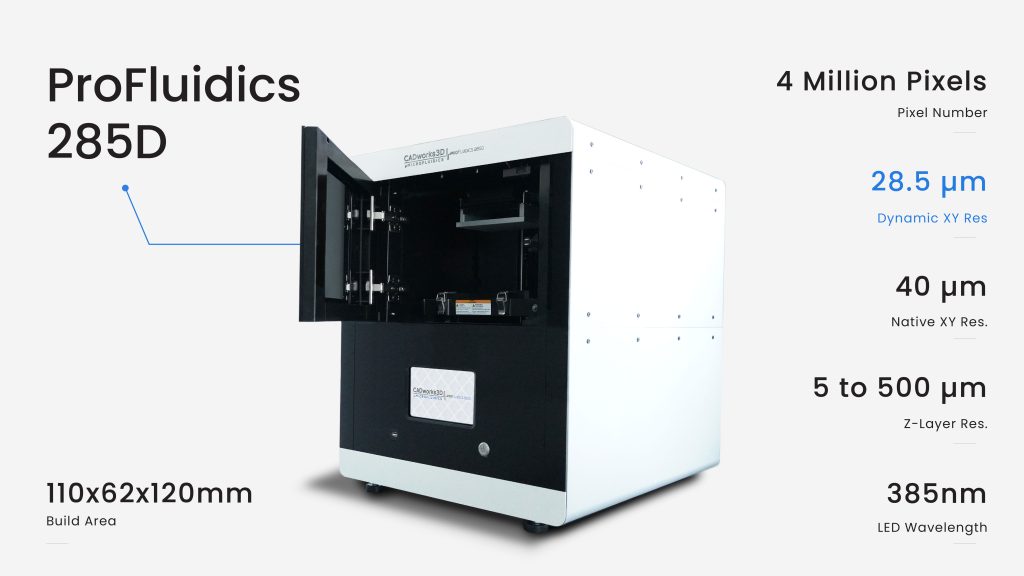

CADworks3D, a Canadian 3D printer producer and 3D materials developer, has introduced ahead a cutting-edge DLP 3D printer designed particularly for microfluidic functions: the ProFluidics 285D. This revolutionary machine reshapes the best way researchers take into consideration microfluidic machine fabrication and presents a substitute for typical fabrication strategies, that are notoriously costly, time-consuming, and labor-intensive.

As a substitute, the ProFluidics 285D opens up workflows which might be streamlined and straightforward to implement. It’s a multi-purpose machine whereby this one 3D printer can produce quite a lot of microfluidic units corresponding to clear units with encapsulated options, grasp molds for PDMS units, and biocompatible units or constructions. Along with CADworks3D’s line of 3D materials, researchers can reliably produce 100µm channels, and smaller relying on the machine’s design.

“CADworks3D’s final objective is to empower microfluidic researchers by offering them with an accessible 3D printing system that’s inexpensive, easy-to-adopt, and versatile – all with out sacrificing high-resolution print high quality.”

How Does Customary DLP 3D Printing Work?

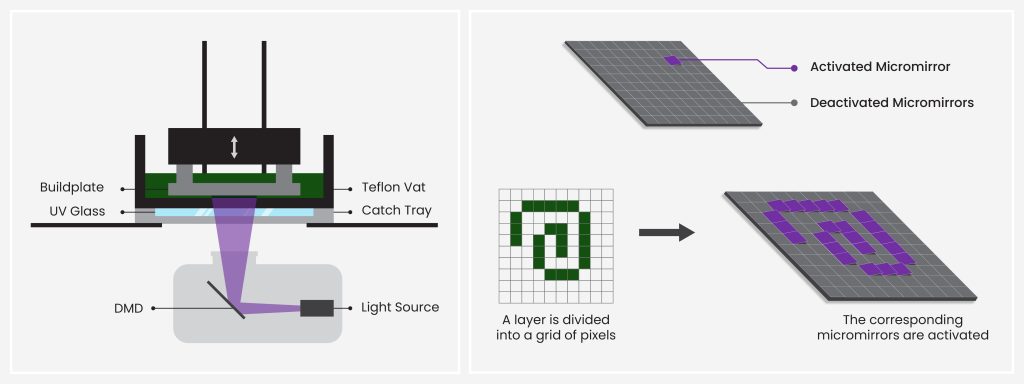

Digital Mild Processing (DLP) is without doubt one of the most typical applied sciences utilized in vat polymerization 3D printing, or resin 3D printing, that interprets digital laptop assisted design (CAD) into usable 3D objects. The spine of this know-how is a digital projector that beams UV mild onto an array of microscopic mirrors referred to as a Digital Micromirror Gadget (DMD). These mirrors mirror the UV mild onto a layer of photosensitive resin and trigger it to treatment within the form of the item being printed. This repeats layer-by-layer till a complete object is created. (See Determine B, Left Facet).

A CAD file is sliced into layers, just like the slice of a CT scan. Every layer is additional divided right into a grid of pixels, with every pixel akin to a person mirror within the DMD. Whereas printing a layer, the projector prompts the mirrors akin to the pixels required to construct the CAD file. When the mirrors are activated, they mirror UV mild onto the liquid resin and treatment it exactly on the pixels. When mirrors are deactivated, they don’t shine, leaving these areas of resin uncured. (See Determine B, Proper Facet) The projected pixel dimension is expressed in micrometers (µm) and coincides with the XY decision listed on a printer’s technical specs.

How the ProFluidics 285D Exceeds Customary DLP 3D Printing:

Print Exceptionally Easy Curves and Shapes

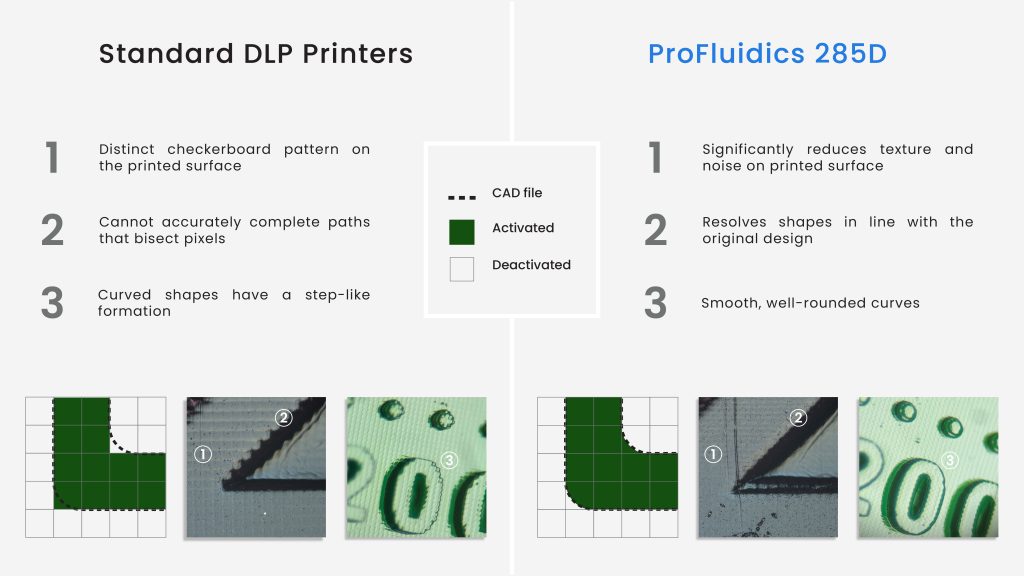

What occurs when elements of the CAD file bisects pixels? Customary DLP printers will consider how a lot of the design covers a given pixel and use a binary rounding operate to both activate or deactivate your complete pixel throughout printing. The result’s a tool with a discernible checkered sample on its floor and a step-like curve (See Determine C, Left Facet). Typically, the machine finally ends up deviating from the unique CAD file.

The ProFluidics 285D addresses this subject with its dynamic pixel benefit. Delivering a dynamic XY decision of 28.5µm, the ProFluidics 285D presents important enhancements in precisely resolving design options – even those who bisect pixels. Printed units intently resemble the meant design, and the incidence of dice patterns and noise is minimized when in comparison with present accessible platforms (See Determine C, Proper Facet). With this know-how, the ProFluidics 285D can efficiently print options with 180-degree turns, advanced serpentine channels, and different intricate geometries.

Utility 1: Clear Encapsulated Units

The ProFluidics 285D can produce totally different classes of microfluidic units, the primary being clear units with encapsulated channels and options.

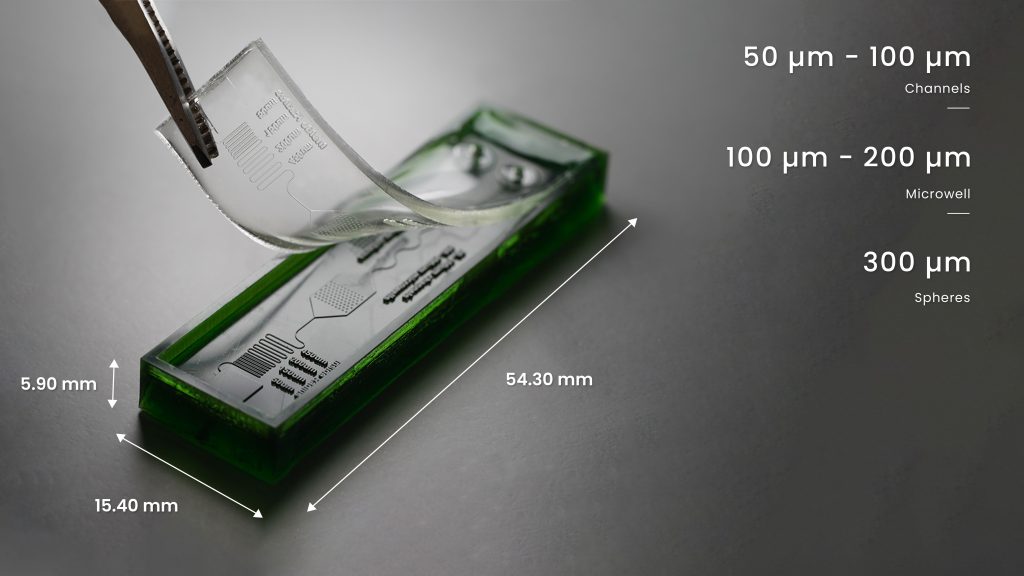

The viability and scale of those encapsulated channels are essential points of those units, and with CADworks3D’s Clear Microfluidics Resin, the ProFluidics 285D excels. Units might be fabricated in only one print job with out assembling a number of elements, and encapsulated channels printed within the XY might be as advantageous as 80μm. Researchers can even create extra novel designs incorporating variations of Z heights, corresponding to helix coils (See Determine D).

Submit-processing is a fast and straightforward process. Relying on the machine’s peak, your complete means of printing a ready-to-use machine might be accomplished in simply over an hour. No floor coating or sharpening is required to attain optical transparency, eliminating a number of, usually tedious, post-processing steps required by different strategies and supplies. The Clear Microfluidics Resin is inert below fluorescent lighting, making it appropriate for microscopy and imaging.

Utility 2: Grasp Mildew for PDMS Units

When utilizing conventional strategies like photolithography, the fabrication of grasp molds is pricey, time-consuming, and arduous. The ProFluidics 285D strikes the fabrication of grasp molds from the clear room and brings them to the bench aspect, thereby considerably accelerating the method. Researchers are given the power to 3D print, clear, and treatment a grasp mildew in only a few hours, and inside one working day, a PDMS machine might be forged and prepared for bonding to a substrate.

With CADworks3D’s Grasp Mildew for PDMS Gadget Resin, you possibly can print molds with channel widths as small as 50um. The printed molds reveal distinctive element and smoothness with a mean measured Ra worth of 0.18µm. These printed grasp molds are very sturdy, can stand up to the temperatures wanted to forged and treatment PDMS in an oven, and can be utilized repeatedly to forged tons of of PDMS units from one grasp.

The photopolymer resin has been formulated in order that there is no such thing as a want for any launch brokers, coatings and different pre-treatment processes for a profitable clear PDMS forged. Moreover, the printed grasp doesn’t leech any chemical substances onto the casted PDMS and so the ensuing PDMS units retain their biocompatible properties.

Utility 3: Biocompatible Units & Constructions

Increasing on the subject of biocompatible units, the ProFluidics 285D operates on an open materials system, permitting customers the power to print with third occasion supplies. It homes a projector outfitted with a 385nm LED mild supply, and as such, the ProFluidics 285D can print with a number of biocompatible 3D resins accessible in the marketplace for makes use of corresponding to bioscaffolds (See Determine F).

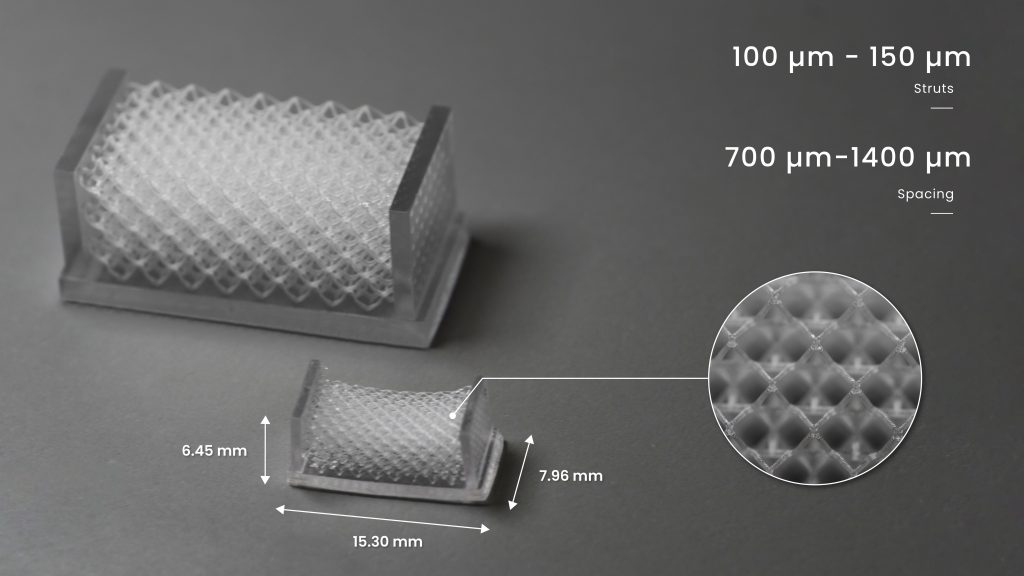

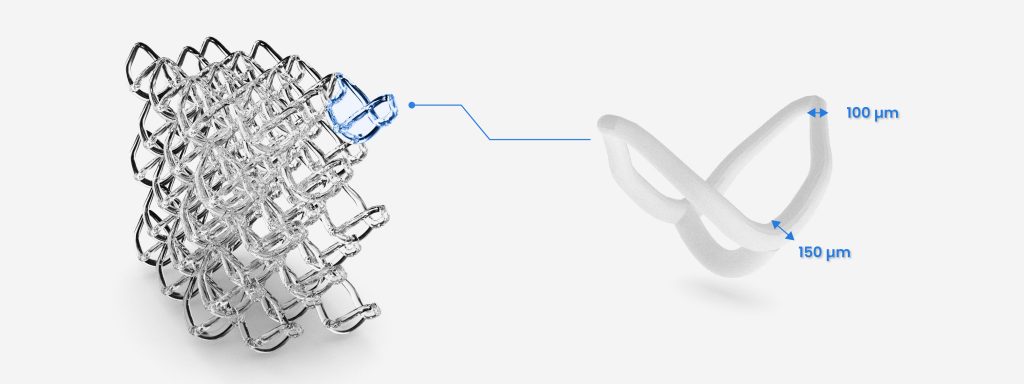

A singular attribute of 3D printing bioscaffolds is the power to print a staggered lattice (See Determine G). This creates a extra random construction that allows cells to develop alongside the bias and facilitate a extra uniform progress distribution. Utilizing the Detax Freeprint Ortho Resin for example, the ProFluidics 285D is ready to print bioscaffolds in simply over an hour with struts as advantageous as 100µm and spacings that vary between 700µm-1400µm.

Made to Empower Microfluidics Analysis

The present 3D market usually presents options for microfluidics which might be repurposed from different industries and because of this there’s usually a spot or a whole mismatch between a researcher’s wants and a printer’s capabilities. Microfluidic units name for printed options which might be sub-100 microns, and plenty of prevailing platforms fail to supply the size or high quality obligatory.

CADworks3D’s ProFluidics 285D and supplies have been formulated solely with microfluidic functions in thoughts. Collectively, they provide a whole package deal to researchers, assembly the demand for finer printed options with minimal channel sizes of 80µm and 50µm for encapsulated and open channels, respectively. It empowers new, modern workflows that save researchers on time, labor, and financial prices. It turns into attainable to supply three to 5 units in only a few hours, the place at 5g per machine, the fee is roughly US$2.05 – US$2.55. In comparison with conventional fabrication strategies or the price of outsourcing fabrication to third-party 3D printing companies, the advantages of working with a whole in-house 3D printing platform turn into obvious.

Featured picture reveals The ProFluidics 285D. Picture by way of CADworks3D.

[ad_2]