[ad_1]

Danish firm Create It Actual is on a mission to assist producers utilizing 3D printing to create not solely finish use merchandise, however distinctive finish use merchandise. On the core of the corporate’s operations is their REALvision software program platform, with which they work with FDM companions to assist obtain top quality prints.

We spoke to Create It Actual CEO, Jacob Nissen, to learn how they’re serving to corporations utilizing additive manufacturing to stage up the standard of their workflows, and in the end, their printed components.

Learn on to study extra.

Create It Actual

Based mostly within the metropolis of Aalborg, the Danish firm has developed their very own REALvision slicing software program for 3D printing, and in addition capabilities as an additive manufacturing lab, specializing in growing manufacturing know-how for custom-made orthopedic and prosthetic merchandise. In addition they provide consultancy companies to varied our bodies who wish to know the best way to get one of the best from additive manufacturing.

“Enable me to emphasise our core focus, [which is] simplifying the complexities of 3D printing to make it accessible to a variety of people, from learners to seasoned business professionals,” stated Nissen.

“We accomplice with 3D print pioneers, CFABs, and producers to discover, develop, and combine extra excellent print capabilities and techniques inside FDM printing”.

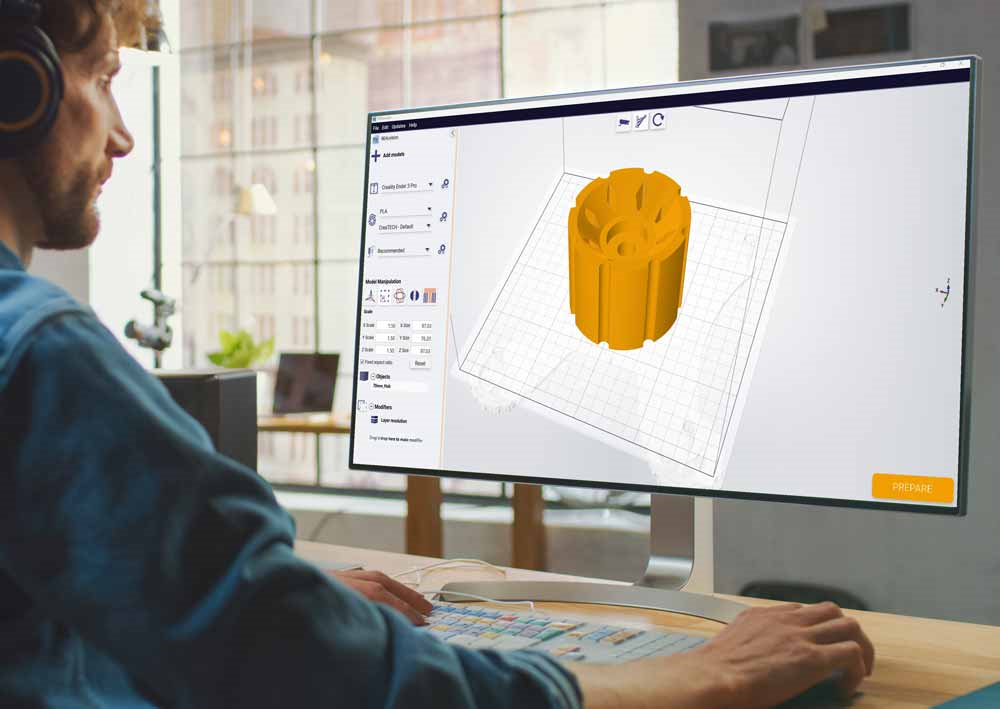

The corporate’s REALvision platform performs a big function in enhancing the accessibility for customers, and is available in a variety of options, together with the standalone REALvision Professional product, customizable whitelabel and enterprise choices, and specialised API options for distinctive purposes.

This tailor-made method doesn’t solely apply to the software program at Create It Actual, but additionally applies to buyer relations on the firm.

“We provide complete consultancy protecting software program and printing, primarily for company customers working in sectors the place additive manufacturing has substantial enterprise implications,” stated Nissen.

“This method caters to companies that desire customized help over looking out by on-line boards for solutions.”

REALvision Overview

As talked about beforehand, the REALVision software program is available in numerous guises, together with a standalone model (REALvision Professional), and a cloud-based model (REALview On-line) which runs in your browser.

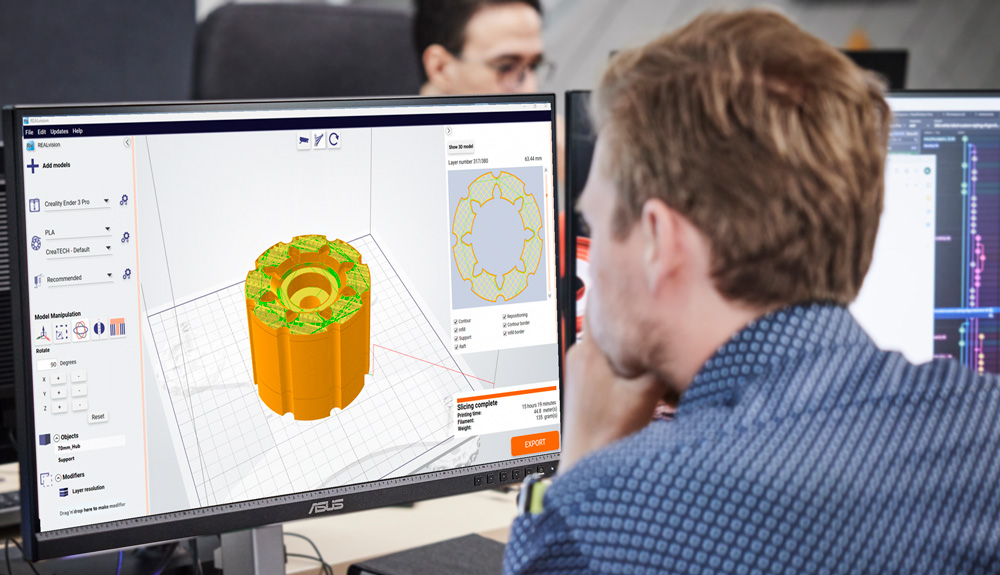

The entire variations provide frequent options together with improved print velocity, mannequin preview, overview of 3D fashions earlier than print, in addition to the flexibility to scale, rotate, and place fashions as wanted. REALvision additionally contains useful tooltips, standardized printing profiles, and materials configurations, making it an intuitive software program platform that doesn’t require a steep-learning curve to be able to be productive.

One excellent characteristic that Create It Actual is eager to level out is the correct predictive capabilities of the software program.

“Our predictions for printing time and filament utilization are calculated exactly, not estimated,” stated Nissen.

“This implies they’re extremely correct and may be relied upon for manufacturing planning”.

The software program may be sampled earlier than buy because of a complimentary trial interval that features entry to help companies. Whereas the default software program has over 20 totally different printer profiles included as customary, in case your printer isn’t at the moment supported, the help employees will work along with the shopper to arrange their new printer profile within the software program.

“In our Company and Enterprise software program partnerships, we provide complete help protecting software program experience and printing consultancy. We function your software program accomplice, offering all-in-one options for something associated to our companions’ printing know-how.”

Not solely is enhanced help supplied, however for customers throughout the Enterprise partnership plan, the corporate gives the choice for customized growth of a extremely bespoke software program answer, far past what the off-the-shelf varieties provide. And for these utilizing the Professional and On-line variations, customers can be happy to know that the software program is constantly rising in functionality additionally.

“The REALvision Professional product frequently evolves”, states the CEO.

“With REALvision Professional, we’re dedicated to performing frequent software program updates, integrating new options and plug-ins, implementing buyer suggestions, common optimization, and extra”.

FDM and Past

The corporate has been targeted on FDM, however they’ve been growing their expertise in different areas too, because of their partnerships and in-house capabilities.

“We’re putting a robust emphasis on enhancing the standard of prints – whereas FDM printing has typically been related to lower-quality PLA prints, it has come a good distance and is now simple to begin with and scalable,” he says.

“Due to this fact, we’re devoted to strengthening the aptitude for producing sturdy prints inside our software program, and options supporting our sturdy print technique can be launched quickly.”

Nissen factors out that past FDM printing, they’ve additionally been working in direction of enhanced high quality in steel printing, the place they’ve been working with a accomplice to develop an revolutionary method utilizing alternate print instructions, that leads to a constant last form, which mirrors the supposed design. The corporate can be broadening its horizons within the thermoplastic printing area, and is working with companions to create options that lead to increased high quality pellet printing.

Printing It Proper

The general ethos of the corporate is targeted on elevated accessibility, and serving to professionals get one of the best out of their very own in-house additive manufacturing capacities.

Additive manufacturing is already accessible to the plenty, however there are numerous ranges of high quality that may be achieved relying on the processes and supplies used. And Create It Actual desires to make it possible for consistency of product may be achieved with the assistance of their software program, and their skilled consultancy companies.

Or as Jacob Nissen extra succinctly places it::

“In less complicated phrases, whereas attaining 90% in 3D printing won’t be too difficult, we excel on the essential last 10% that turns a very good prototype into an distinctive last product prepared for finish prospects”.

If you need to know extra about REALvision Professional, or strive it out as a part of the complimentary trial interval, then head on over to this hyperlink.

And if you want to view the opposite software program options they provide, or avail of their consultancy companies to your skilled additive manufacturing wants, then head on over to the foremost Create It Actual web site.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.

[ad_2]