[ad_1]

Time is operating out! Nominate now for the 3D Printing Business Awards 2023.

Is 3D printing sustainable? Not everybody agrees.

3D Printing Business visited AM Summit 2023, Scandinavia’s largest additive manufacturing convention, to listen to from additive manufacturing business specialists on core subjects – together with sustainability and 3D printing.

The Copenhagen-based occasion noticed debate surrounding what sustainability means in additive manufacturing, and whether or not 3D printing is definitely sustainable in any respect.

“I’ve heard a lot sustainable this and that right here, and no one has a clue whether or not it’s truly sustainable or simply extra sustainable than one thing else, and that is precisely the issue” argued Michael Hauschild (PhD), Head of DTU Centre for Absolute Sustainability.

This yr’s occasion hosted a variety of panel discussions. Of specific curiosity was an analysis of Danish AM Hub’s new CO2e carbon emissions calculator, and insights into digital distributed manufacturing.

Learn extra insights from AM Summit Denmark 2023

Danish AM Hub’s CO2e calculator

Throughout AM Summit 2023, Marie Langer, CEO of 3D printer producer EOS, highlighted the advantages of the corporate’s 3D printing Value and Carbon Calculator. Nonetheless, EOS isn’t the one group to develop a CO2 calculator for the additive manufacturing course of.

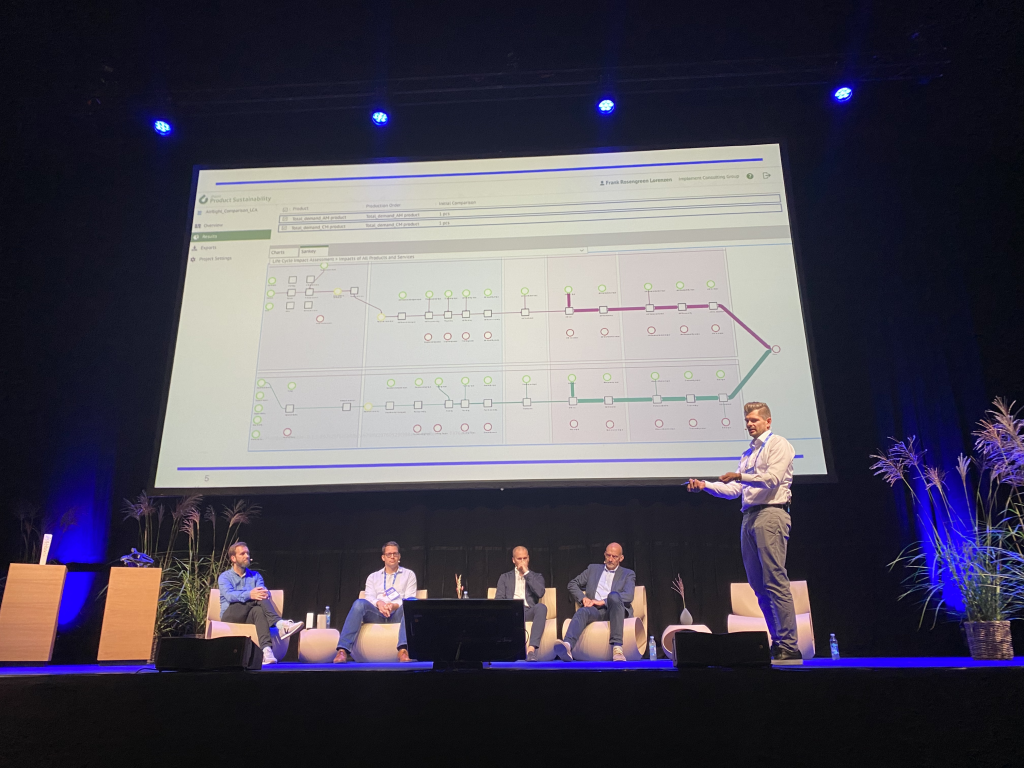

Danish AM Hub has developed its personal instrument, the CO2e calculator. This seeks to visualise the sustainability advantages of 3D printing in comparison with conventional manufacturing strategies.

Throughout this yr’s convention, a panel mentioned the utility of the instrument, highlighting a lot of case research exhibiting the CO2e calculator in motion. The dialogue additionally outlined the challenges related to precisely defining and calculating sustainability in additive manufacturing.

“It’s a very groundbreaking initiative for us,” commented AM Hub CEO Frank Rosengreen Lorenzen.

In accordance with Lorenzen, a key intention of this instrument is to show the dialogue round in manufacturing. “Manufacturing is all about effectivity and it’s all about time. Why not additionally speak about sustainability?” Danish AM Hub additionally needed to create a instrument that conducts CO2 calculations earlier than the manufacturing stage “as a result of the planet doesn’t care a few life cycle evaluation (LCA) if we don’t use it to vary our habits.”

The CO2e calculator itself is “actually easy,” acknowledged Lorenzo. Evaluating a conventional manufacturing course of, corresponding to milling, with a 3D printing course of, the calculator outputs one quantity – Highlighting the quantity CO2 saved or gained by utilizing additive manufacturing.

The CO2e calculator was Developed in collaboration with the Copenhagen-based Implement Consulting Group. Jan-Markus Rödger, Sustainability Technique Associate on the group, defined that the instrument assesses all phases of a merchandise life cycle, “ranging from the uncooked materials, to the processing, to the transportation, to the precise product, the use section and the top of life.”

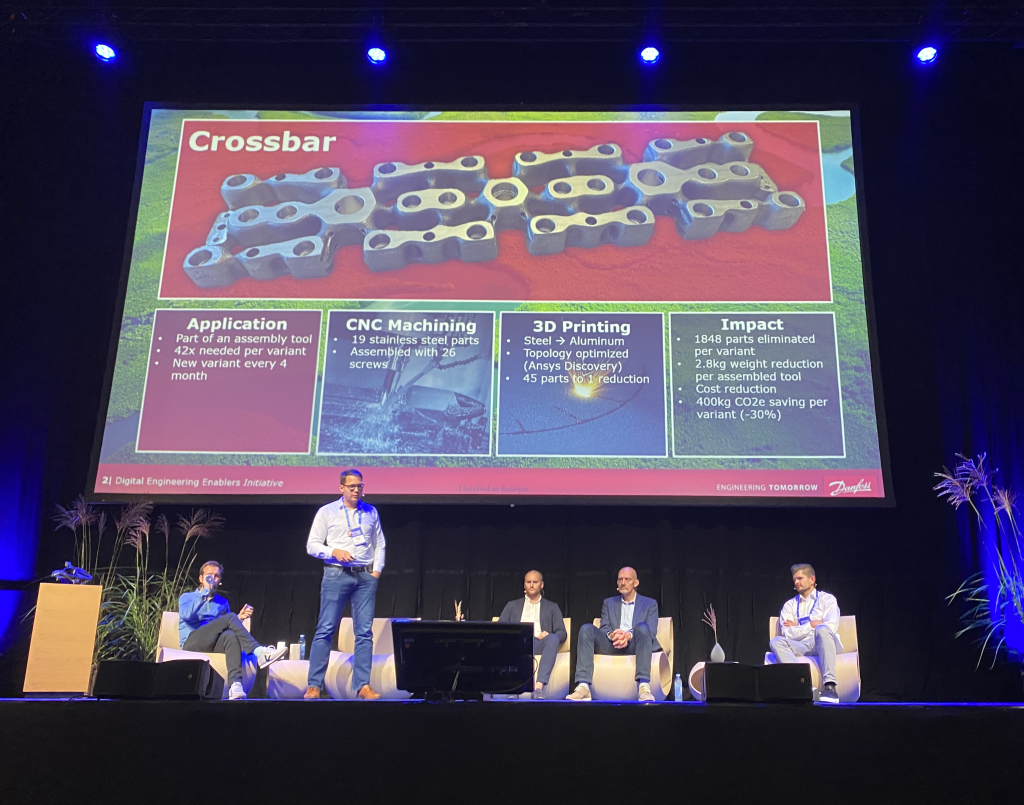

One use case of the calculator was outlined by Niklas Franke, Head of AM and Manufacturing Simulation at Danfoss. This Denmark-based producer has a large product portfolio which incorporates compressors, pumps, and warmth exchangers. “The frequent theme is admittedly that these merchandise use power, and we are able to create worth for our clients by lowering this power,” defined Franke.

As a part of its mission to scale back power and enhance sustainability in manufacturing, Danfoss carried out a CO2 calculation on a metallic crossbar part utilizing Danish AM Hub’s instrument. This part is a part of an meeting instrument in one in all Danfoss’s factories. Franke defined that 42 of those instruments are wanted for a product variant, with a brand new variant wanted roughly each 4 months.

Beforehand CNC machined out of metal, the corporate now 3D prints the half. In accordance with Franke, 3D printing has allowed Danfoss to make use of aluminum moderately than metal, and consolidate the variety of manufactured elements from 45 to only one. Consequently, the corporate has eradicated 1848 elements per variant, with a 2.8kg weight discount per assembled instrument.

The CO2e calculator helped Danfoss decide whether or not the additive manufacturing course of is extra sustainable than the CNC various. “On this case, we are able to say sure, it’s 30% extra sustainable as a result of we save 400kg of CO2 per variant,” defined Franke.

The CO2e calculator was additionally employed by hypercar producer Zenvo Automotive A/S. The Danish firm used the instrument to find out the sustainability of its 3D printed suspension upright elements for its TSR-S sports activities vehicles. In accordance with Alberto Solera, Technical Director – TS Collection on the firm, the CO2e calculator broke new floor. Zenvo has “by no means actually seemed on the environmental affect till now with the calculator that you simply guys have offered.”

Danish AM Hub’s instrument highlighted the burden financial savings supplied by additive manufacturing. The SLS 3D printed elements save 800 grams in comparison with these produced with sand casting methods.

“There’s 4 of those on every automobile. So in our world, that’s price a considerable sum of money,” defined Solera. The CO2e calculator additionally highlighted additive manufacturing as lowering carbon emissions by 225% in comparison with the traditional methodology.

Calculating absolute sustainability in AM

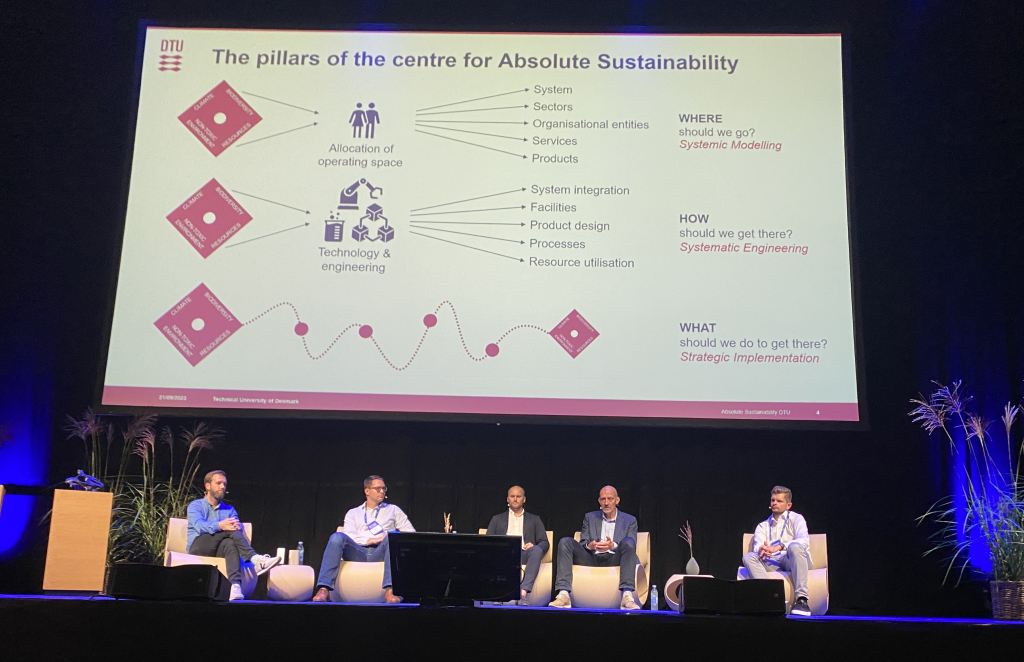

While the advantages of 3D printing over standard manufacturing will be clearly displayed with the calculator, Hauschild believes that the dialog round sustainability requires extra readability.

While acknowledging the worth of LCA’s for evaluating 3D printing to various manufacturing strategies, Hauschild’s focus on the DTU Centre for Absolute Sustainability revolves round whether or not “one thing is sustainable in absolute phrases.”

In accordance with Hauschild, a key limitation of the CO2e calculator is that it solely signifies if one methodology is extra sustainable than one other, and “doesn’t inform us whether or not it’s sustainable.”

However how can absolute sustainability be measured in additive manufacturing? In accordance with Hauschild, this may be achieved by framing the environmental affect of 3D printing inside “biophysical boundaries.” As an illustration, the targets outlined by The Paris Settlement are highlighted as “absolute necessities” for sustainability.

These necessities embody limiting world warming to 1.5℃ above pre-industrial ranges, greenhouse gasoline emissions peaking by 2025, and attaining carbon neutrality by 2050. Due to this fact, Hauschild believes that the sustainability of additive manufacturing must be measured in opposition to particular benchmarks corresponding to these.

“If we wish to speak about whether or not AM is sustainable in absolute phrases, we have to see the way in which we use it, and whether or not it should allow us to fulfill the wants inside these biophysical boundaries,” added Hauschild.

Hauschild additionally highlighted information high quality as being one of many largest challenges relating to conducting LCA’s and assessing sustainability.

“It’s actually necessary to get the info proper the place it issues,” defined Hauschild. “In case your processes or the precise materials you might be utilizing are actually driving the affect, then it is advisable look into how good the info truly is. If it’s not adequate, then it is advisable make investments time to get higher information.”

Decentralizing provide chains by way of Distributed Digital Manufacturing

Securing provide chains and decentralizing spare half manufacturing is at present an enormous theme throughout the 3D printing business. Certainly, questions surrounding the way forward for 3D printing within the provide chain gained lots of consideration earlier this yr at AM Discussion board in Berlin.

Throughout AM Summit, a panel dialogue highlighted how digital distributed manufacturing (DDM) can be utilized to create extra resilient and sustainable decentralized provide chains.

“25% of Danish business has adopted AM to some extent at this time. However what we hear after we speak to small and medium-sized companies is that that is sometimes throughout the product adjustments class. We don’t see as a lot after we speak in regards to the worth chain inside AM” defined Amalie Kaysen, Head of Product and Portfolio at Danish AM Hub. Kaysen famous that “there’s an enormous potential in wanting on the worth chain piece,” with DDM seen as key to optimizing worth chains and provide chains.

“Additive manufacturing is a very necessary know-how after we speak about digital distributed know-how,” acknowledged Stephen Howard, Account Supervisor at 3D printing software program and companies developer Materialise.

Howard pointed to the significance of software program suppliers in “enabling digital collaboration between plenty of completely different stakeholders within the manufacturing course of, bringing collectively producers, bringing collectively designers and engineers and permitting them to collaborate digitally and remotely.”

“We positively see extra firms shifting into or making an attempt to make the most of decentralized manufacturing,” added Howard. “I feel it permits for lots extra flexibility, and so they’re doing this on account of world pressures and on account of provide chain shortages.”

This sentiment was echoed by Pieter Ruijssenaars, CEO of 3D printing provide chain software program supplier DiManEx. Ruijssenaars argued that DDM is crucial as a result of “the world will endure extra from social political issues or pure disasters sooner or later, so you possibly can’t depend on bodily provide chains.”

Ruijssenaars additionally pointed to the significance of DDM by way of sustainability, claiming that “AM and digitisation lets you mix issues like value saving and contributing to a extra sustainable world in your provide chain.”

Additive manufacturing and digitization is ready to “play a key position within the new provide chains of the long run to make them extra resilient, extra future proof or extra sustainable in a number of methods,” Ruijssenaars added.

Mental Property (IP) and knowledge safety was one other key theme touched upon in the course of the panel dialogue.

“Whenever you’re working in a distributed manufacturing setup, you progress round information everywhere in the world. So you actually need to deal with that,” commented Jesper Winther Andersen, CEO and Founding father of customized in-ear product producer Earfab.

Key to securing this information is software program, in keeping with Howard. “It’s a very key position that software program suppliers play. You really want to take into accounts how software program can play a task in IP.” As an illustration, Howard pointed to a collaboration between Materialise and San Francisco-based software program developer Identify3D, with the 2 firms working to safe IP by way of blockchain and digital rights administration.

Howard additionally highlighted the digital warehouse as being an space the place IP performs a vital position, particularly with regard to the oil and gasoline and aerospace industries. “I feel lots of these firms are actually terrified of shifting to distributed manufacturing as a result of they’re actually terrified of the IP getting leaked out and these elements being manufactured elsewhere.”

When it comes to scalability, software program was once more highlighted as being key to DDM. “Software program might be the crux to interconnectivity,” defined Jeremy Haight, Chief Principal Engineer – Additive Manufacturing & Superior Ideas at world wind turbine producer Vestas Wind Programs A/S. “If you would like scalability, it’s important to have interconnectivity.”

Haight additionally pointed to the importance of modularity, and the significance of with the ability to adapt one know-how to “do a number of issues throughout the worth chain, or produce a number of several types of elements which might be certified.”

What’s the way forward for DDM? Ruijssenaars expects two quick developments. The primary is that there might be extra hybrid variations of DDM primarily based on completely different enterprise use instances, with extra firms 3D printing regionally. Secondly, Ruijssenaars believes that enormous language fashions, corresponding to ChatGPT, will see extra growth and use on this house. These instruments can “add to our analytics and make it extra clever, correct, and supply extra insights.”

Subscribe to the 3D Printing Business publication to maintain updated with the most recent 3D printing information. You can too observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits the CO2e calculator dialogue panellists. Photograph by 3D Printing Business.

[ad_2]