[ad_1]

Cloud and API-based 3D engineering platform supplier Metafold has introduced new options geared toward selling wider acceptance of 3D printing and lightweighting as alternate options to standard manufacturing strategies.

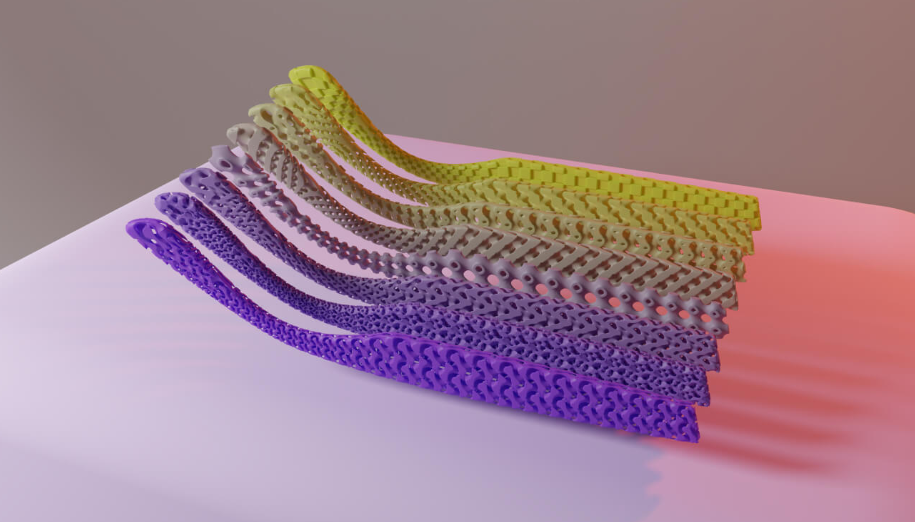

The replace incorporates compression simulation, conformal mapping for lattice buildings, and substantial alterations to each the consumer interface (UI) and API. These adjustments purpose to enhance accessibility for engineers and software program builders concerned in additive manufacturing design. Further options comprise template workflows, prolonged help for import and export file codecs, improved undertaking administration capabilities for groups, and a revamp of the software program structure to expedite releases of latest options sooner or later.

“Additive manufacturing shouldn’t be so arduous, but the mind-boggling geometric complexities have prevented corporations from adopting superior 3D printing capabilities,” shared Dr. Elissa Ross, Co-Founder and CEO of Metafold. “With our new launch, we’re making an attempt to assist extra corporations see all the advantages of additive manufacturing by making our breakthrough geometry kernel accessible to extra engineers and extra software program builders. They will create new sneakers, discover biotech developments, or make warmth change developments and different improvements whereas leaving the mathematical intricacies to Metafold.”

Simplifying additive manufacturing

A major addition is the introduction of one-click simulation for 3D engineered elements, making certain excessive precision in predictive efficiency for mechanical compression. This simulation permits engineers to shortly assess and finalize designs with out counting on bodily take a look at prints or exterior simulation purposes. Conformal mapping, seamlessly built-in into Metafold, streamlines mapping lattice cells to an element boundary. By permitting engineers to focus on product design, this integration ensures that Metafold takes on the duty of effectively resolving advanced geometry.

Designers profit from UI updates, experiencing a extra user-friendly work atmosphere that lessens the cognitive load linked to software program navigation, thus affording extra time for artistic ideation. The improved API, constructed on modern net requirements, not solely supplies extra samples but additionally expands entry to next-generation geometry processing capabilities. It holds the potential to speed up the time it takes for web-based purposes with advanced geometry to achieve the market.

“The Additive business is at a crucial level the place design and simulation merely don’t dwell as much as the potential of the know-how,” mentioned Jacques Perrault, 3D Design Pioneer and Influencer. “Metafold’s distinctive strategy challenges the established order, ushering in a brand new class of additive software program constructed for scale and empowered by the cloud.”

For a restricted time, Metafold is providing open beta entry to simulation capabilities at three simulations per 30 days within the free version of the Metafold Platform. Simulation and conformal mapping are anticipated within the Skilled version sooner or later. events can discover the open beta right here.

Easy additive design and simulation

Steel 3D printer developer Meltio launched Meltio House software program and the Meltio Robotic Cell, responding to the rising demand for its Meltio Engine Robotic Integration. The Meltio Robotic Cell, a turn-key answer for 3D printing steel elements, gives a safer and extra environment friendly technique. Meltio House, a user-friendly toolpath generator, helps varied robotic manufacturers, offering planar and nonplanar toolpaths. The software program ensures correct 3D printing by simulating robotic actions, minimizing errors. Optimizing the capabilities of the Meltio Engine, Meltio House delivers steady updates and supplies a user-friendly interface, all at a aggressive annual subscription value.

Engineering software program developer nTop launched a software program replace named nTop 4, aiming to handle challenges in additive manufacturing (AM) design and manufacturing. nTop 4 consists of Area Optimization, a generative design know-how streamlining AM design by managing advanced parameters and enhancing half efficiency. Implicit Interop eliminates information change bottlenecks, lowering file sizes and facilitating seamless information switch. nTop Automate improves design automation, now obtainable for Linux, enabling cost-effective cloud computing. nTop Speed up gives customized coaching and workshops to maximise affect.

Learn all of the 3D Printing Business protection from Formnext 2023.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing business? Go to 3D Printing Jobs for a collection of roles within the business.

Featured picture exhibits rework advanced lattices to completely match half boundary with out sacrificing design intent. Photograph through Metafold.

[ad_2]