[ad_1]

The 3D Printing Trade Evaluation of the 12 months continues.

By many measures, the most important 3D printing information story in 2023 was M&A exercise round a number of of the biggest corporations within the business, together with a uncommon 3D printing unicorn. As our detailed timeline of the takeover plans by Stratasys, Desktop Steel, 3D Programs and Nano Dimension exhibits, plans for consolidation started in 2021. Nonetheless, the arrival of activist investor Murchinson and subsequent conflict with Nano Dimension’s CEO made the beforehand behind the scenes battle for management entrance web page information.

Away from M&A exercise, February 2023 noticed a number of updates round analysis tasks and materials developments. Elsewhere, Fabric8Labs concluded a $50M Sequence B funding spherical.

Learn on for February 3D printing information from Nano Dimension, iFactory3D, IIT Bombay, IperionX, Sakuu, and extra.

3D Programs, Desktop Steel, Stratasys and Nano Dimension takeover talks

In July 2022, Stratays modified their articles of affiliation to enact what is usually often known as a poison tablet protection to potential company takeovers. The submitting of this shareholder Rights Plan sought to guard the corporate from an undesirable hostile takeover, following Nano Dimension’s buy of a 12.1% stake in Stratasys.

The rationale for this exercise would develop into extra obvious in February 2023, as Murchinson Ltd., a comparatively unknown activist fund, made public its plans to accumulate Nano Dimension. On the time, Murchinson was the corporate’s largest shareholder, holding 5.1% of its excellent shares. Nano Dimension was definitely a pretty goal, as a consequence of amassed money on the steadiness sheet of $1 billion.

What started as a small-scale dispute, would quickly snowball into a fancy net pulling 3D Programs, Stratasys and Desktop Steel into an escalating battle to regulate a probably monopolistic 3D printing behemoth.

The money steadiness of Nano Dimension drew the eye of Murchinson, who sought to alter the board and deploy the funds in an alternate method. Nano Dimension had already spent a number of the funds raised from a number of funding rounds to buy over 12% of Stratasys’ excellent shares, in addition to NanoFabrica, Admatec/Formatec, Essemtec, International Inkjet Programs, and DeepCube.

In an open letter to its fellow shareholders, Murchinson expressed its dissatisfaction with Nano Dimension CEO and chairman Yoav Stern’s management, describing it as “poor capital allocation and unlucky company governance.”

Murchinson pointed to Nano Dimension’s share worth as lagging behind ‘its solely self-reported peer Stratasys by 27% over the previous two years,’ with the agency’s inventory trades at a ‘substantial rebate’ to the steadiness sheet. Murchison argued that this mirrored market concern that Stern would proceed to ‘destroy worth.’

Over the course of 2023, and by way of frequent missives issued by the Stern, it grew to become obvious that Nano Dimension had carried out important due diligence throughout the 3D printing sector, by some value determinations over 100 potential acquisition targets. This strategic transfer was made to counteract the type of consideration Nano Dimension was receiving from Murchinson, setting the stage for the most important 3D printing M&A saga of the 12 months.

3D printing analysis initiatives

Analysis helps decide the viability of a specific know-how earlier than it’s uncovered to a bigger viewers. Preserving this in thoughts, Korea Electrotechnology Analysis Institute (KERI) and the Ulsan Nationwide Institute of Science and Expertise (UNIST) researchers developed core know-how for 3D printed sensible contact lenses, with low-power monochrome shows showcasing augmented actuality functionalities like stay navigation.

Revealed in Superior Science, this know-how makes use of Prussian blue ink micro-patterns, promising cost-effective augmented actuality gadgets. The Arduino Uno-controlled prototype showcases preset photos and holds promise for real-time navigation by projecting GPS-based instructions. Testing on dwelling human eyes is the following step earlier than potential commercialization.

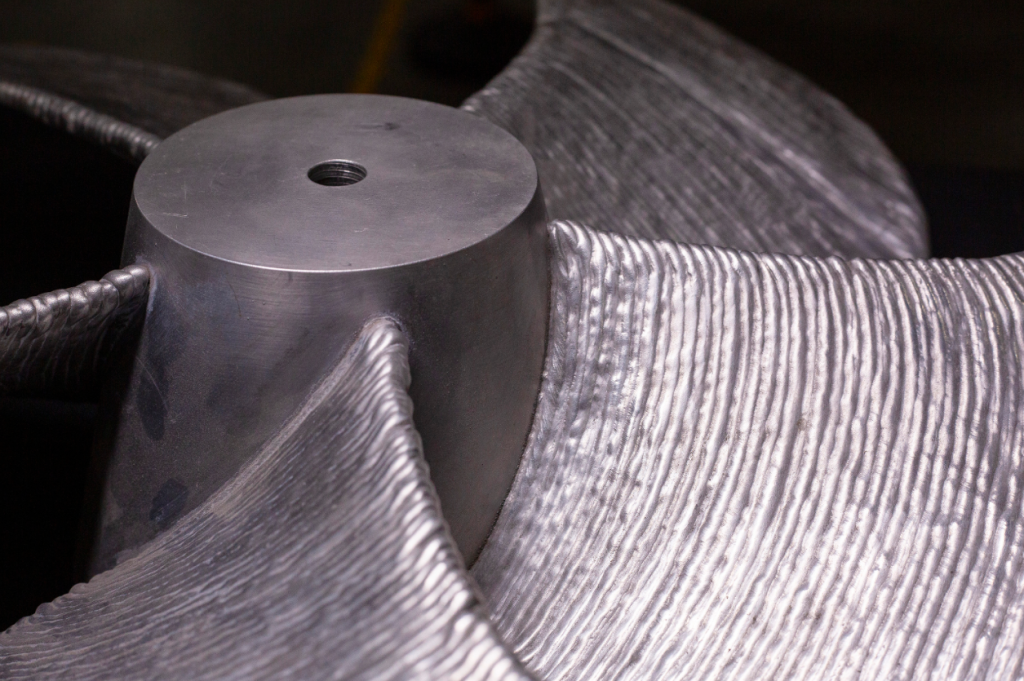

The Revolutionary Manufacturing Cooperative Analysis Heart (IMCRC) and AML3D, efficiently commercialized a high-strength aluminum wire feedstock for welding and 3D printing. Developed in collaboration with Deakin College, the wire requires solely half-hour of thermal processing after printing.

AML3D aimed to reshape manufacturing processes, significantly in shipbuilding and aviation, addressing challenges related to present aluminum alloys. Supported by IMCRC, the collaboration makes advancing metallic half manufacturing extra environment friendly and cost-effective, probably boosting Australia’s competitiveness within the business.

German start-up iFactory3D commissioned a thesis exploring the financial viability of 3D belt printers for serial manufacturing in manufacturing. The research in contrast iFactory3D’s One Professional 3D belt printer to conventional Cartesian FFF/FDM printers.

Findings revealed decrease variable bills for the 3D belt printer in all circumstances, with a big discount in manufacturing prices as a consequence of automation. The unrestrained size of the set up house and steady manufacturing capabilities contributed to value financial savings, making the 3D belt printer economically favorable for batch manufacturing in small to medium enterprises.

In different information, Dr. Pushkar Kamble, (Ph.D.) Institute Publish-Doctoral Fellow, Speedy Manufacturing (RM) Lab, at IIT Bombay, supplied insights on the ICE 3D printing analysis.

IIT Bombay’s proprietary ICE 3D printer’s Sub-Zero Additive Manufacturing (SZ-AM) course of makes use of deionized water and glycerol resolution to create ice objects at -30°C. The SZ-AM course of entails simultaneous meting out of fabric and assist liquids, with managed heating to keep away from nozzle clogging. Ice parts can be utilized as funding casting patterns, providing benefits over wax, as ice reduces assist elimination challenges.

Supplies shaping the 3D printing business

Supplies play a pivotal position within the 3D printing sector. Because of this, materials launches have additionally been a spotlight in February. In alliance with Tethon3D, Mechnano developed a high-temperature, inflexible electrostatic discharge (ESD) materials, dubbed C-Lite resin, utilizing Mechnano’s carbon nanotube know-how (CNT).

C-Lite is designed for customized nano-uniform ESD elements enduring high-temperature wave soldering processes. The fabric enhances manufacturing agility, enabling quick-turn fabrication with ultra-high accuracy. Trilogy-Internet‘s reflow assessments confirmed C-Lite’s dimensional stability and sturdiness after 50 cycles.

Uniformity Labs unveiled UniFuse AlSi10Mg Aluminum powder with superior Laser Powder Mattress Fusion (LPBF) printing parameters at 50um and 90um layer thickness. UniFuse AlSi10Mg demonstrates superior mechanical properties, floor end, printing yield, and half reliability. Uniformity’s developments allow a 75% quicker construct fee in comparison with opponents on the similar layer thickness, showcasing additive manufacturing’s potential for industrial-scale manufacturing, says the corporate.

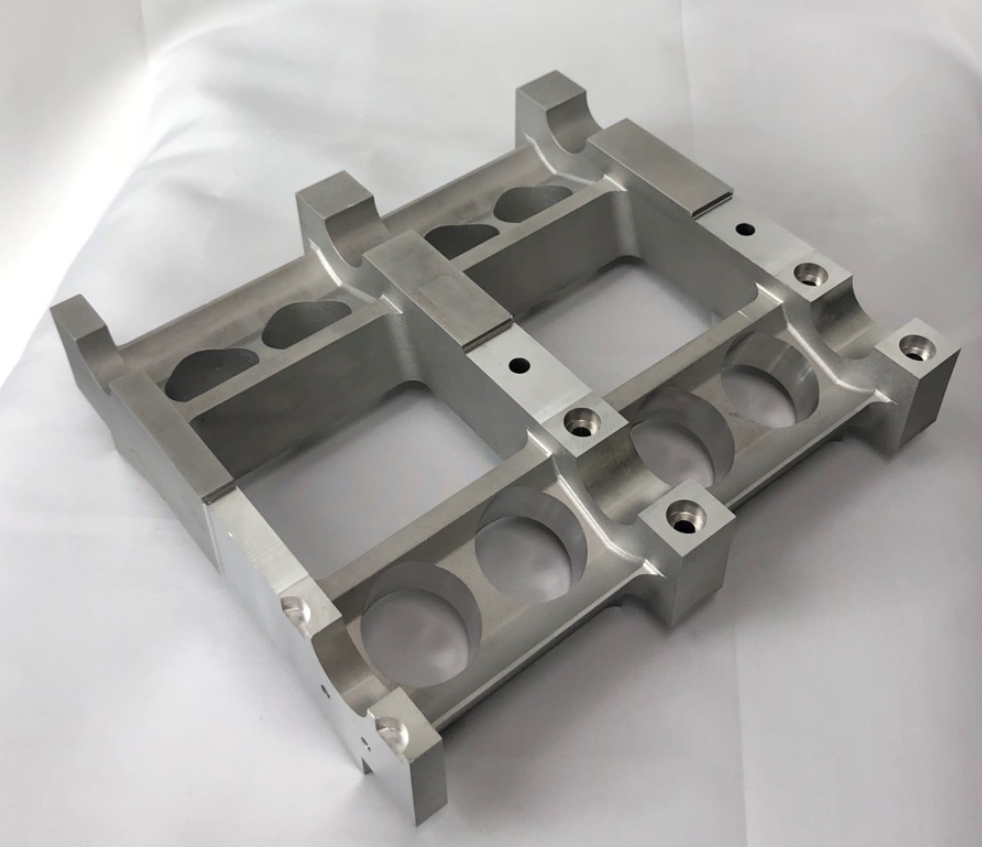

Elsewhere, 3D printer producer Mantle Inc. highlighted profitable implementations of its metallic 3D printing know-how at Nicolet Plastics and Westec Plastics. Each serving the medical machine market, these injection molders utilized Mantle’s know-how to streamline toolmaking processes.

Nicolet Plastics considerably diminished toolmaker time from 180 hours to 12.5 hours, reaching quicker manufacturing of molded element samples. Westec Plastics adopted Mantle’s know-how to generate 75-95% full H13 inserts, slicing tooling prices and permitting toolmakers to concentrate on vital processes.

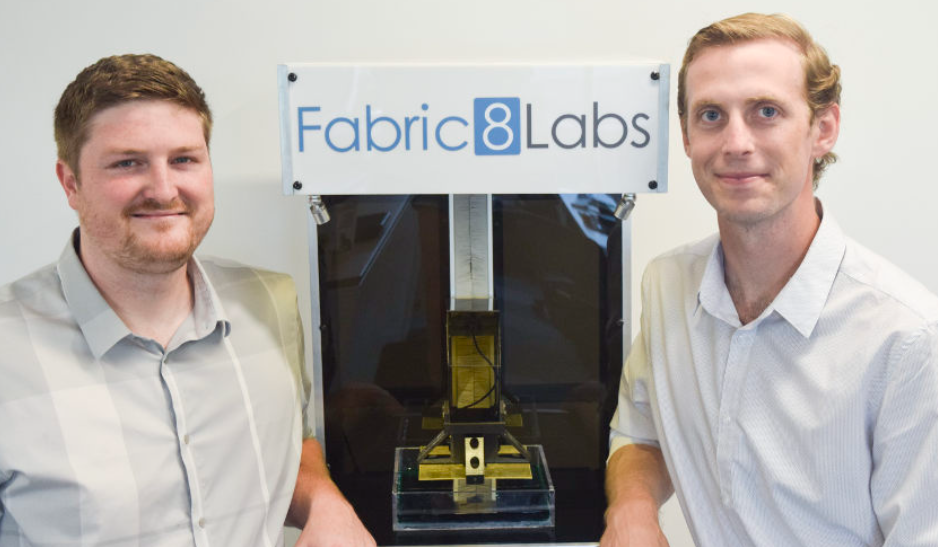

Fabric8Labs’ $50M Sequence B funding hits the headlines

Fabric8Labs secured $50 million in a Sequence B funding led by New Enterprise Associates (NEA), with participation from Intel Capital, imec.XPAND, and extra.

Fabric8Labs aimed to make use of the funding to increase the corporate’s Electrochemical Additive Manufacturing (ECAM) know-how and set up a pilot manufacturing facility. The know-how is geared toward resolving challenges in energy density, thermal administration, and sustainability throughout numerous purposes, says the corporate.

2023: 3D Printing Trade overview of traits and information.

2022: 3D Printing Trade overview of traits and information.

Learn all of the 3D Printing Trade protection from Formnext 2023.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

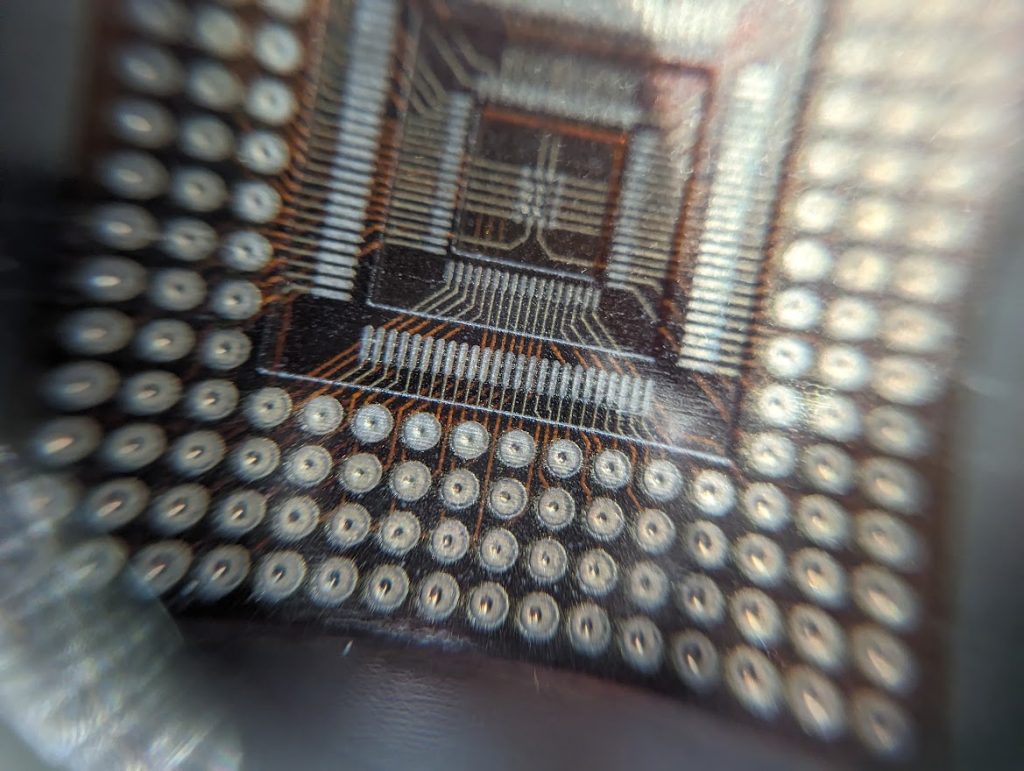

Featured picture exhibits Nano Dimension 3D printed electronics. Photograph by Michael Petch.

[ad_2]