[ad_1]

The design presents superior IGBT know-how and customizable testing choices for early-stage improvement and efficiency evaluation in motor management.

The traction inverter is essential in electrical and hybrid electrical automobiles, serving because the cornerstone for environment friendly and efficient car propulsion. It’s a pivotal part that transforms direct present (DC) from the car’s battery into alternating present (AC) to energy electrical motors. Past mere energy conversion, traction inverters management motor velocity and torque, allow regenerative braking, and improve general power effectivity. Their means to seamlessly combine with numerous car programs, together with superior driving applied sciences, marks them as important within the evolution of electrical car efficiency and performance. This makes the traction inverter a part and a key enabler within the journey in the direction of extra sustainable and superior automotive applied sciences.

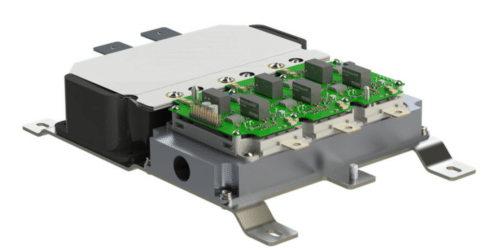

The VE-Trac Direct Analysis Package by Onsemi contains a VE-Trac Direct energy module connected to a cooling jacket, a 6-channel Gate driver board, and a DC Hyperlink capacitor. The package doesn’t include a PWM controller or exterior present sensors. Customers are required to offer their very own PWM controller to function the system. Moreover, exterior present sensors are crucial for closed-loop motor management. The package presents customers the chance to evaluate the efficiency of the VE-Trac Direct energy module within the preliminary phases of inverter improvement. It may be utilized as a double pulse tester for measuring key switching parameters or as a 3-phase inverter for motor management functions.

The package is designed for EV/HEV Traction Inverter functions, able to dealing with as much as 150 kW. It consists of the VE-Trac Direct NVH820S75L4SPB, that includes an 820 A, 750 V Area cease 4 IGBT/Diode chipset. The design additionally accommodates an automotive remoted excessive present and high-efficiency IGBT gate driver, the NCD57000, with inner galvanic isolation. Moreover, it incorporates fundamental safety options like Over Temperature Safety (OTP) and Desaturation (Desat). To enhance these elements, the design is supplied with a customized Movie DC Hyperlink capacitor, rated as much as 500 VDC and 500 µF, making certain environment friendly energy storage and administration throughout the system.

The Gate Driver Board on this setup operates with a management energy starting from 9 V to fifteen V. The DC Hyperlink Voltage varies from 0V to 500V, with the higher restrict set by the capacitor’s capability. It may possibly deal with a peak collector part present (1ms) from -1640 A to 1640 A, constrained by the utmost IGBT/FWD junction temperature, which ranges from -40°C to 175°C. After a brief circuit occasion, a compulsory wait time is 1 second. The PCB temperature is maintained at 85°C, and the system operates at a switching frequency of 12 kHz. Moreover, the coolant temperature is regulated between -40 °C and 65°C.

Onsemi has examined this reference design. It comes with a Invoice of Materials (BOM), schematics, and so forth. You’ll find further information in regards to the reference design on the corporate’s web site. To learn extra about this reference design, click on right here.

[ad_2]