[ad_1]

Courtesy: Arrow Electronics

Lithium-ion (Li-Ion) batteries are a standard vitality storage technique for electrical autos, providing very excessive vitality density in comparison with all current battery applied sciences. Nevertheless, to maximise efficiency, it’s important to make use of a battery monitoring system (BMS) to securely handle the charging and discharging cycles, thereby extending the battery’s lifespan. This text will introduce the structure and operation modes of BMS, in addition to the product options and benefits of the BMS gadgets launched by ADI.

Superior BMS can help electrical autos in effectively extracting a major quantity of cost from the battery pack throughout operation. It might precisely measure the battery’s state of cost (SOC) to increase battery runtime or cut back weight, and improve battery security includes avoiding electrical overloads within the type of deep discharge, overcharging, overcurrent, and thermal overstress.

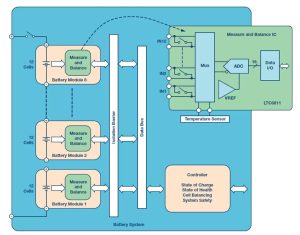

The first perform of the BMS is to observe the bodily parameters throughout battery operation, making certain that every particular person cell throughout the battery pack stays inside its protected working space (SOA). It displays the charging and discharging currents, particular person cell voltages, and the general battery pack temperature. Primarily based on these values, it not solely ensures the protected operation of the battery but additionally facilitates SOC and state of well being (SOH) calculations.

One other essential perform supplied by the BMS is cell balancing. In a battery pack, particular person cells could also be linked in parallel or sequence to attain the specified capability and working voltage (as much as 1 kV or increased). Battery producers try to supply equivalent cells for the battery pack, however attaining excellent uniformity isn’t bodily sensible. Even small variations can result in variations in charging or discharging ranges, and the weakest cell within the battery pack can considerably impression the general efficiency. Exact cell balancing is an important function of the BMS, making certain the protected operation of the battery system at its most capability.

Wi-fi BMS removes communication wiring, decreasing complexity

Electrical car batteries are composed of a number of cells linked in sequence. A typical battery pack, with 96 cells in sequence, generates over 400 V when charged at 4.2 V. The extra cells within the battery pack, the upper the voltage achieved. Whereas the charging and discharging currents are the identical for all cells, it’s vital to observe the voltage on every cell.

To accommodate the big variety of batteries required for high-power automotive programs, a number of battery cells are sometimes divided into a number of modules and distributed all through the whole accessible area within the car. A typical module consists of 10 to 24 cells and might be assembled in numerous configurations to suit varied car platforms. Modular design serves as the muse for big battery packs, permitting the battery pack to be distributed over a bigger space, thus optimizing area utilization extra successfully.

With a view to assist a distributed modular topology within the excessive EMI atmosphere of electrical/hybrid autos, a sturdy communication system is crucial. Remoted CAN bus is appropriate for interconnecting modules on this atmosphere. Whereas the CAN bus gives a complete community for interconnecting battery modules in automotive purposes, it requires many extra parts, resulting in elevated prices and circuit board area. Furthermore, if trendy Battery Administration Methods (BMS) undertake wired connections, it comes with vital drawbacks. Wiring turns into a difficult challenge as wires must be routed to completely different modules, including weight and complexity. Wires are additionally inclined to select up noise, requiring extra filtering.

Wi-fi BMS is a novel structure that eliminates the necessity for communication wiring. In a wi-fi BMS, interconnection between every module is achieved by wi-fi connections. The wi-fi connection in massive battery packs with a number of cells reduces wiring complexity, lowers weight, decreases prices, and enhances security and reliability. Nevertheless, wi-fi communication faces challenges in harsh EMI environments and sign propagation obstacles attributable to RF-shielding steel parts.

Embedded wi-fi networks can enhance reliability and precision

The SmartMesh embedded wi-fi community, launched by ADI, has undergone on-site validation in Industrial Web of Issues (IoT) purposes. It achieves redundancy by using path and frequency variety, offering connections with reliability exceeding 99.999% in difficult environments resembling industrial and automotive settings.

Along with enhancing reliability by creating a number of redundant connection factors, wi-fi mesh networks additionally prolong the functionalities of BMS. The SmartMesh wi-fi community permits versatile placement of battery modules and improves the calculation of battery SOC and SOH. That is achieved by gathering extra knowledge from sensors put in in places beforehand unsuitable for wiring. SmartMesh additionally gives time-correlated measurement outcomes from every node, enabling extra exact knowledge assortment.

ADI has built-in the LTC6811 battery stack monitor with ADI SmartMesh community know-how, representing a major breakthrough. This integration holds the potential to boost the reliability of huge multi-cell battery packs in electrical and hybrid autos whereas decreasing prices, weight, and wiring complexity.

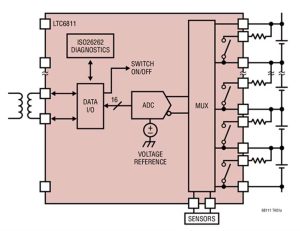

The LTC6811 is a battery stack monitor designed for multi-cell battery purposes. It might measure the voltage of as much as 12 series-connected cells with a complete measurement error of lower than 1.2mV. The measurement of all 12 cells might be accomplished inside 290μs, and a decrease knowledge acquisition fee might be chosen for top noise discount. The LTC6811 has a battery measurement vary of 0V to 5V, appropriate for many battery chemistry purposes. A number of gadgets might be daisy-chained to concurrently monitor very lengthy high-voltage battery stacks. The system consists of passive balancing for every cell, and knowledge change happens on both facet of an isolation barrier, compiled by the system controller. The controller is liable for calculating SOC, controlling battery balancing, checking SOH, and making certain the whole system stays inside protected limits.

Furthermore, a number of LTC6811 gadgets might be daisy-chained, permitting simultaneous monitoring of lengthy high-voltage battery stacks. Every LTC6811 has an isoSPI interface for high-speed and RF-resistant distant communication. When utilizing LTC6811-1, a number of gadgets are linked in a daisy-chain, and all gadgets share one host processor connection. When utilizing LTC6811-2, a number of gadgets are linked in parallel to the host processor, and every system is individually addressed.

The LTC6811 might be powered straight from the battery pack or an remoted energy supply and options passive balancing for every battery cell, together with particular person PWM obligation cycle management for every cell. Different options embody a built-in 5V regulator, 5 general-purpose I/O strains, and a sleep mode (the place present consumption is lowered to 4μA).

Cell balancing is employed to optimize battery capability and efficiency

Cell balancing has a major impression on the efficiency of batteries as a result of even with exact manufacturing and choice, delicate variations can emerge between them. Any capability mismatch between cells can result in a discount within the total capability of the battery pack. Clearly, the weakest cell within the stack will dominate the efficiency of the whole battery pack. Cell balancing is a method that helps overcome this challenge by equalizing the voltage and SOC between cells when the battery is totally charged.

Cell balancing know-how might be divided into passive and energetic varieties. When utilizing passive balancing, if one cell is overcharged, the surplus cost is dissipated right into a resistor. Sometimes, a shunt circuit is employed, consisting of a resistor and an influence MOSFET used as a swap. When the cell is overcharged, the MOSFET is closed, dissipating the surplus vitality into the resistor. LTC6811 makes use of a built-in MOSFET to manage the charging present for every monitored cell, thus balancing every cell being monitored. The built-in MOSFET permits for a compact design and might meet a 60 mA present requirement. For increased charging currents, an exterior MOSFET can be utilized. The system additionally gives a timer to regulate the balancing time.

Then again, energetic balancing includes redistributing extra vitality amongst different cells within the module. This method permits for vitality restoration and decrease warmth technology, however the drawback is that it requires a extra advanced {hardware} design.

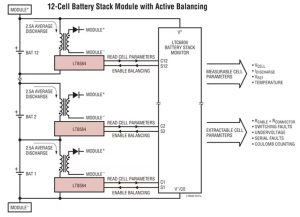

ADI has launched an structure utilizing LT8584 to attain energetic balancing of batteries. This structure actively shunts charging present and returns vitality to the battery pack, addressing the problems related to passive shunt balancers. Vitality isn’t dissipated as warmth however is as an alternative reused to recharge the remaining batteries within the stack. The structure of this system additionally tackles an issue the place a number of cells within the stack attain a low protected voltage threshold earlier than the whole stack’s capability is depleted, leading to lowered runtime. Solely energetic balancing can redistribute cost from stronger cells to weaker ones, permitting weaker cells to proceed supplying energy to the load and extracting a better proportion of vitality from the battery pack. The flyback topology permits cost to maneuver forwards and backwards between any two factors within the battery pack. In most purposes, the cost is returned to the battery module (12 cells or extra), whereas in different purposes, the cost is returned to the whole battery stack or auxiliary energy rails.

The LT8584 is a monolithic flyback DC/DC converter designed particularly for energetic balancing of high-voltage battery packs. The excessive effectivity of the switch-mode regulator considerably will increase the achievable balancing present whereas decreasing warmth dissipation. Moreover, energetic balancing permits for capability restoration in stacks of mismatched batteries, a function not attainable with passive balancing programs. In typical programs, over 99% of the whole battery capability might be achieved.

The LT8584 options an built-in 6A, 50V energy swap, decreasing the design complexity of the appliance circuit. The system operates fully counting on the cells which it’s discharging, eliminating the necessity for advanced biasing schemes usually required when utilizing an exterior energy switches. The allow pin (DIN) is designed to seamlessly coordinate with the LTC680x sequence battery stack monitor ICs. Moreover, when used together with LTC680x sequence gadgets, the LT8584 gives system telemetry capabilities, together with present and temperature monitoring. When disabled, the LT8584 usually consumes lower than 20nA of whole static present from the battery.

Conclusion

The important thing to low-emission autos lies in electrification, but it surely additionally requires good administration of vitality sources (resembling lithium-ion batteries). Improper administration might render the battery pack unreliable, considerably decreasing the protection of the car. Each energetic and passive battery balancing contribute to protected and environment friendly battery administration. Distributed battery modules are simple to assist, and so they can reliably transmit knowledge to the BMS controller, whether or not by wired or wi-fi means, enabling reliable SOC and SOH calculations. ADI gives a complete vary of BMS parts that may help clients in accelerating BMS improvement, making certain extra environment friendly administration of the operational effectivity and security of electrical car batteries.

[ad_2]