[ad_1]

Researchers have found a way for 3D printing nanoscale optical-grade glass at considerably decrease temperatures in comparison with conventional approaches. By using a hybrid organic-inorganic polymer resin, they’ve opened up new potentialities for the manufacturing of silica glass, which holds immense potential for varied technological purposes.

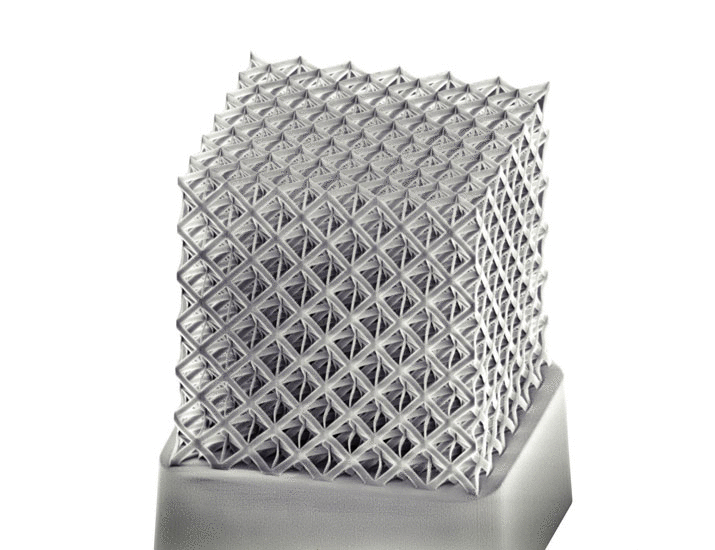

The standard strategies of producing glass depend on excessive temperatures and restrictive forming methods. Nevertheless, a staff of researchers from Karlsruhe Institute of Expertise and College of California Irvine has developed a sinter-free, two-photon polymerization (TPP) 3D printing method that permits for the creation of clear fused silica glass nanostructures at a mere 650 levels Celsius.

The distinctive properties of silica glass, akin to optical transparency and distinctive thermal, chemical, and mechanical traits, make it ultimate for microsystem applied sciences like micro-optics, photonics, microelectromechanical methods (MEMS), and microfluidics. This breakthrough paves the best way for the seamless integration of glass elements in these cutting-edge applied sciences.

Beforehand, the sintering temperatures required for particle-based silica glass resins posed challenges for on-chip manufacturing as a result of melting factors of different electrical circuit supplies. Nevertheless, the low-temperature 3D printing method developed by the staff overcomes this hurdle, permitting for the fabrication of glass constructions straight onto substrates with distinctive precision.

The diminished firing temperature requirement of this methodology affords thrilling prospects for the direct integration of miniaturized gadgets onto substrates like optical fibers and chips. This achievement not solely permits automation of the manufacturing course of but additionally ensures excessive precision, revolutionizing the manufacturing of nanoscale glass elements.

You possibly can learn the analysis paper titled “A sinterless, low-temperature path to 3D print nanoscale optical-grade glass” over at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.

[ad_2]