[ad_1]

Engineers at Princeton College are utilizing lasers to handle a key concern with 3D printed cement – its susceptibility to fractures. By evaluating the fabric’s resistance to cracking, the researchers intention to increase using additive manufacturing in cement-based constructions and develop superior supplies by modern designs and features.

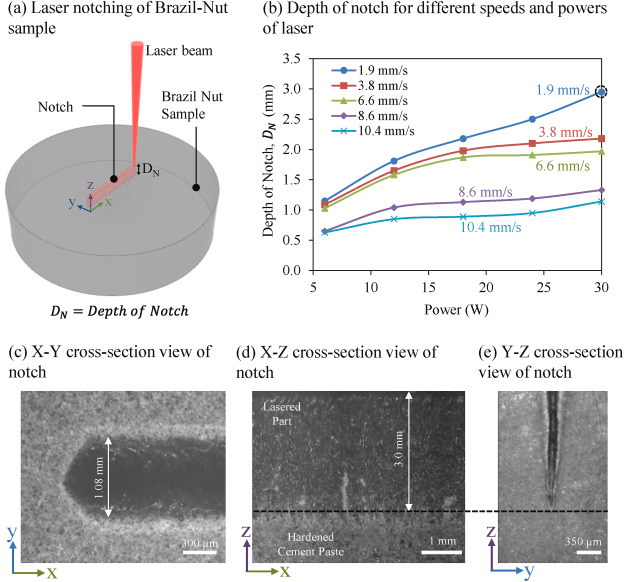

Whereas 3D printing gives effectivity and flexibility, 3D printed concrete has proven an inclination to crack, particularly within the areas between totally different layers. That is attributed to non-uniform microstructures ensuing from the layering course of. To realize a deeper understanding of this cracking phenomenon, the Princeton researchers have launched a brand new testing methodology that employs lasers to create exact grooves in 3D-printed cements. The laser’s energy and pace will be managed to find out the grooves’ depth and form, enabling extra correct testing in comparison with standard strategies.

The research, printed within the journal Cement and Concrete Composites, highlights the potential for 3D-printed concrete to match or surpass the energy of forged concrete by characterizing its fracturing properties. The power to comprehensively perceive the fracture conduct of 3D-printed cement-based supplies is essential for advancing this know-how on a bigger scale.

By leveraging additive manufacturing’s design freedom and materials structure, there are alternatives to create stronger and extra sturdy supplies. The researchers at Princeton, led by Reza Moini, are devoted to enhancing additive manufacturing methods for cement-based supplies, aiming to beat the structural weaknesses brought on by water-rich movies fashioned throughout extrusion.

Laser Notching

Utilizing lasers as an alternative of bodily instruments like saws to create notches for testing permits for extra exact analysis of the microstructures and interfaces between layers. This strategy allows researchers to evaluate the fabric’s resistance to cracking beneath numerous situations, resembling pressure and shear.

A fracture check much less generally utilized in concrete supplies, often called the Brazil-Nut check, was proposed to facilitate the characterization of fracture toughness of 3D-printed cementitious supplies in Mode-I/II in two orthogonal instructions. A laser processing of hardened brittle cement paste supplies was proposed for the primary time to permit for the creation of a pointy V-shaped notch with constant and managed depth.

Princeton’s ongoing analysis focuses on investigating architected supplies and fracture traits to additional improve the understanding of 3D-printed concrete. The workforce’s work has gained recognition, with graduate college students receiving awards for his or her contributions at trade conferences.

You’ll be able to learn the complete paper, titled “Fracture and transport evaluation of heterogeneous 3D-Printed lamellar cementitious supplies” over at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.

[ad_2]