[ad_1]

A DIY tube furnace for creating ICs

— August 14th, 2023

Fashionable built-in circuit (IC) chips can have transistors as small as two nanometers, which is simply about 10 silicon atoms laid end-to-end. At that scale, fabrication appears extra like chemistry than any type of bodily manipulation — a machinist isn’t carving tiny transistors into silicon wafers. For a lot of sorts semiconductors, the fabrication course of requires a really highly effective furnace. Should you’re considering creating your individual ICs, then YouTuber ProjectsInFlight has a video explaining find out how to construct your individual furnace.

This can be a design for a tube furnace that may attain 1200°C, just like the sort that labs purchase for a lot of 1000’s of {dollars}. Producing that a lot warmth in a controllable method is just not a trivial job and that is rather more difficult than developing a furnace for one thing like aluminum casting. The heating aspect is a coil of nichrome wire, which wraps round a quartz glass tube that may stand up to the warmth. A ridiculous quantity of insulation surrounds the tube and wire to comprise the warmth.

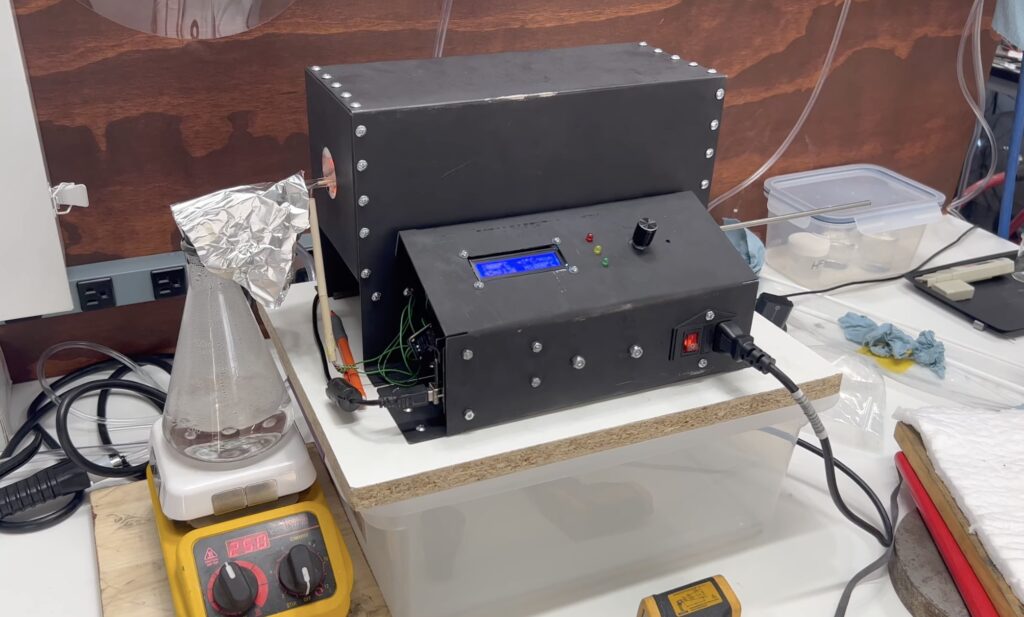

Nichrome wire heats up by resistance when a present passes by, so you can simply join it to an influence supply. However that wouldn’t be controllable, so ProjectsInFlight created a management board primarily based on an Arduino UNO Rev3 board. Like a 3D printer controller dealing with scorching finish temperature by proportional–integral–spinoff (PID), this makes use of a closed-feedback PID loop to modulate energy to the nichrome wire in response to readings from a thermocouple. The management interface has a dial for setting the goal temperature and a 16×2 character LCD to point out the present temperature detected by the thermocouple. The Arduino makes use of a solid-state relay (SSR) to modulate the facility going by the nichrome wire.

A easy sheet steel enclosure homes the tube and, in a separate space, the management electronics. The furnace appears to be able to safely reaching the specified temperature, so ProjectsInFlight can now use it for semiconductor experiments.

You’ll be able to comply with any responses to this entry by the RSS 2.0 feed.

You’ll be able to depart a response, or trackback from your individual website.

[ad_2]