[ad_1]

The newest electrolyzer expertise boosts hydrogen manufacturing effectivity, marking a major step in direction of sustainable and efficient inexperienced hydrogen power options.

Within the quest for sustainable power options, extra environment friendly hydrogen manufacturing strategies are paramount. Developments in electrolyzer expertise are essential for harnessing inexperienced hydrogen power successfully and sustainably.

Researchers from the Faculty of Chemical Engineering at UNIST have developed a expertise to reinforce the efficiency of electrolyzers in hydrogen manufacturing. This innovation is a notable stride in direction of commercialising inexperienced hydrogen manufacturing expertise.

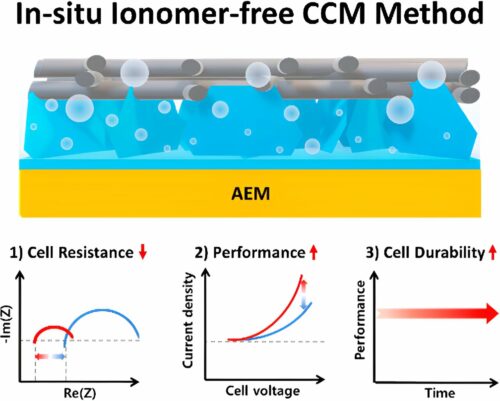

The crew has devised a brand new in-situ, ionomer-free methodology for creating catalyst-coated membranes (m-CCM). This system permits for the direct synthesis and integration of a catalyst layer between the anion trade membrane (AEM) and the fuel diffusion layer, eliminating the necessity for anion trade ionomers. This methodology overcomes the constraints of conventional membrane electrode meeting (MEA) fabrication processes.

The Anion Change Membrane Water Electrolyzer (AEMWE), created utilizing the m-CCM methodology and that includes a platinum group metal-free anode catalyst, has proven superior efficiency to conventional MEA-based electrolyzers.

This m-CCM strategy enhances interfacial resistance, optimises catalyst utilization, and ensures shut contact. It achieves an industrial-grade present density of 1 A cm-2 at a cell voltage of 1.79 Vcell. The strategy can also be exceptionally sturdy, sustaining over 200 hours of steady electrolysis at 50°C in 1 M KOH electrolyte.

As well as, the AEMWE reaches a present density of 500 mA cm-2 at 1.913 Vcell, displaying a low degradation charge of 0.58 mV h-1 over 260 hours of steady operation at a present density of 250 mA cm-2. This efficiency is maintained whereas working at 50°C utilizing ultrapure water.

This expertise’s enhanced efficiency and stability stem from the direct cultivation of the catalyst layer, which removes the need for ionomers sometimes employed in membrane electrode meeting manufacturing. The m-CCM methodology’s exclusion of ionomers and its direct catalyst layer progress optimise the interface between the membrane, catalyst, and help, bettering efficiency and stability.

Reference: Tae-Hoon Kong et al, In-Situ Ionomer-Free Catalyst-Coated Membranes for Anion Change Membrane Water Electrolyzers, ACS Vitality Letters (2023). DOI: 10.1021/acsenergylett.3c01418

[ad_2]