[ad_1]

Time is operating out! Nominate now for the 3D Printing Business Awards 2023.

3D Printing Business not too long ago attended AM Summit 2023, which was held at Ok. B. Hallen in Copenhagen. Organized by Danish AM Hub, this annual occasion is Scandinavia’s largest additive manufacturing convention.

With over 600 guests in attendance, AM Summit 2023 drew audio system from throughout the additive manufacturing sector to supply insights by means of numerous keynote speeches and panel discussions. 46 additive manufacturing corporations additionally exhibited in the course of the occasion, affording a possibility for guests to discover key 3D printing choices for a variety of purposes.

The overarching theme of AM Summit 2023 was “sustainability,” with a transparent concentrate on the advantages of 3D printing as a extra sustainable various to conventional manufacturing.

“The core of our journey is a elementary perception that AM has a lot extra to supply,” acknowledged Danish AM Hub CEO Frank Rosengreen Lorenzen. “The additive manufacturing technique merely have to be the tactic that holds the biggest potential when it comes to sustainability.”

Danish AM Hub is a key advocate of sustainability in additive manufacturing. It was not too long ago introduced that the group has been made a core associate of Formnext 2023, the world’s largest 3D printing commerce present. Together with delegates from Sweden, Norway and Finland, Danish AM Hub will lead this 12 months’s Nordic associate area in Frankfurt. The group will “put sustainability on prime of the agenda within the AM business the place it belongs” at Formnext 2023, in response to Lorenzen.

EOS and “accountable manufacturing”

One firm that claims to try for sustainability in additive manufacturing is 3D printer producer EOS. Marie Langer, EOS CEO, took to the stage in Copenhagen to show how the corporate is pursuing “accountable manufacturing.”

Taking the reins of the corporate in 2019, Langer claims that her first resolution was to “put sustainability on the middle of what we do, as a result of I actually consider that know-how and innovation can and has to contribute to make the world a greater place.”

Certainly, again in 2021 EOS launched its first sustainability report, with the corporate establishing an inside Carbon Accounting and Controlling (CAC) system “to actually be capable of determine how a lot CO2 footprint emissions we’re contributing to, and in addition setting ourselves targets for the long run.”

What’s extra, Langer additionally highlights how EOS desires to “put accountable manufacturing on the core of what we do,” launching a “Accountable Merchandise” idea to realize this. Right here, the corporate works with analysis and audit companions to make sure that as soon as a product is launched, any claims relating to particular CO2 reductions could be audited and authorized. Langer emphasised that it’s critical for purchasers to have actual proof relating to the corporate’s sustainability claims to keep away from greenwashing, asserting that “greenwashing is not going to be any answer for the local weather disaster we’re operating into.” Along with certification, clients are additionally given paperwork which present all the life cycle evaluation (LCA) of their EOS merchandise.

The primary “Accountable Merchandise” had been launched within the polymer supplies area throughout Formnext 2022, nevertheless Langer confirmed that extra supplies will comply with sooner or later. Presently, EOS has two “Accountable Polymer” powders available on the market, the PA 1101 ClimateNeutral and the PA 2200 CarbonReduced.

Moreover, EOS’s Good Fusion software program, additionally launched throughout Formnext 2022, was highlighted by Langer as being “an enormous sport changer within the metallic business.” This software program is alleged to considerably reduce materials waste, decreasing assist by 80% in a single use case.

Langer additionally pointed to EOS’s Value and Carbon Calculator as encouraging sustainable manufacturing for its clients. Developed by the corporate’s Additive Minds and Sustainability groups, this on-line software gives entry to clear value and carbon evaluation, visible analytics, value sensitivity evaluation, report technology, data-driven design to fulfill buyer targets, and customised circumstances for buyer pricing.

In the end, the calculator makes it straightforward “for our clients taking a look at particular purposes to calculate carbon emissions and in addition share the pricing to actually consider the inexperienced enterprise case,” commented Langer.

Is 3D printed meat the reply to sustainable meals?

The meat business was additionally highlighted as a key contributor to world sustainability challenges throughout this 12 months’s Copenhagen-based occasion. Daniel Dikovsky, CTO at meals 3D printing agency Redefine Meat, took to the stage to focus on how the corporate’s 3D printed steak is offering a viable and sustainable various to conventional meat merchandise.

Based on Dikovsky, “Beef is creating an enormous, enormous drawback which is comparable solely to the transportation sector within the quantity of greenhouse gasoline emission, within the land that it occupies, the feed that we develop for these animals, and in addition in water consumption and antibiotics launched to the bottom.” Certainly, cows reared for meat are stated to require roughly 8.5x extra water than people each day.

To fight these challenges, Redefine Meat employs plant-based tissue engineering know-how to 3D print steak merchandise which can be stated to precisely replicate the feel and style of their cow-reared alternate options. Right here, the corporate employs a “bottom-up” strategy, utilizing it’s personal formulated plant-based “fats, muscle, blood, connective tissue, and different parts” to create the meat-free merchandise. The corporate has developed a digital course of to precisely mix these parts and create the specified textures.

Again in 2018, Redefine Meat created its first proof of idea, highlighting a capability to extrude a number of totally different supplies and create a marble meat construction. This course of was developed additional, with the corporate producing its first tenderloin in 2021 that possessed the “traits that you’d anticipate to have from a steak.”

The corporate’s product portfolio has now grown to incorporate a variety of 3D printed steak merchandise which have been launched to market, and are being served in 2122 eating places world wide.

Dikovsky additionally pointed to the event of the corporate’s proprietary meat-free steak 3D printer, referred to as the Angus System. “The machine is designed to fulfill the market wants for quick manufacturing at low prices,” commented Dikovsky. “There may be a variety of work that’s being carried out not solely to point out proof of idea, however make it commercially viable.”

One key problem confronted on this course of pertains to meals security necessities. “It’s not like making polymers or plastics or metals, it’s completely totally different,” added Dikovsky, who highlighted the hygiene and temperature challenges that have to be met within the manufacturing of this 3D printer. “We have to remedy all of those necessities with a view to put a manufacturing system in a meals manufacturing lab.”

Dikovsky emphasizes that the Angus 3D printer is “very scalable” and may obtain “actual full scale business manufacturing” sooner or later.

Dikovsky argues that the environmental advantages of 3D printed meat are substantial. Based on Dikovsky, Redefine Meat’s New-Meat merchandise scale back water consumption by 96%, reduce land occupation by 98% and scale back greenhouse gasses by 91% in comparison with conventional farming strategies.

3D printing for sustainable structure and development

Sustainable structure and development was one other key theme throughout AM Summit 2023. Various audio system, panelists, and exhibitors reminiscent of 3D printed furnishings firm recozy, emphasised the sustainability advantages of utilizing additive manufacturing for architectural and development purposes.

AM Hub’s Programme Director Eleanora Orsetti highlighted that development is an business which the group is eager to work with. “We’ve various challenges associated to the development business. It’s answerable for 35% of the supplies used, 37% of waste manufacturing, and 40% of CO2 emissions globally,” Commented Orsetti.

Orsetti additionally famous that 3D printing in development is essentially based mostly round concrete, arguing that this isn’t probably the most sustainable choice. “We try to consider methods to take a step ahead, how we are able to have extra versatile and non permanent constructions, how we are able to mix totally different supplies and strategies, but additionally methods to have improved design freedom and contain native communities to design their very own areas.”

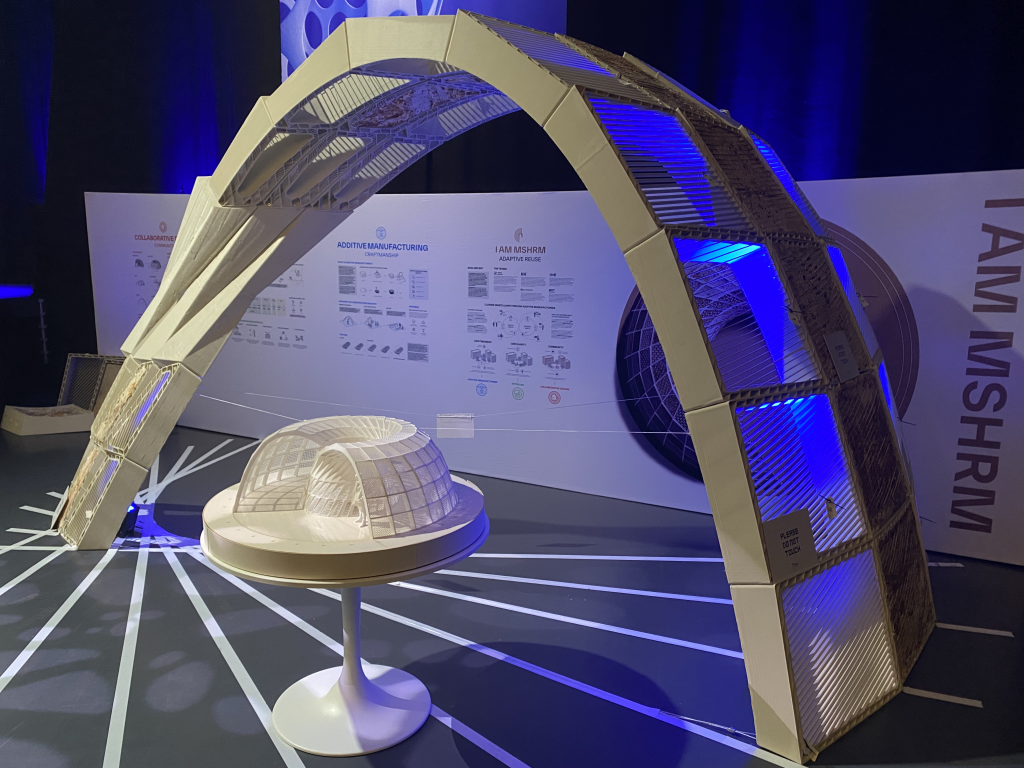

With this purpose in thoughts, Danish AM Hub has collaborated with Bjarke Ingels Group to run the I AM MSHRM challenge. This collaboration has seen the design and part-construction of a 3D printed, quickly deployable, and simply assembled non permanent construction. Key to this challenge is materials effectivity, with the construction’s frames being 3D printed utilizing plastic waste, regionally sourced sugarcane and cornstarch.

Catherine Huang, a Companion at Bjarke Ingels Group, argued that additive manufacturing gives vital benefits when it comes to materials effectivity. “It has such a possibility to scale back waste by printing solely the components that you simply want and with out the necessity for conventional molds and varieties. So that you save on materials.”

The 3D printed frames are stuffed with mycelium, a naturally occurring fungi, to create the construction’s partitions. “As an alternative of requiring 20 years to develop a tree, you possibly can develop mycelium paneling in 20 days or much less,” defined Huang. “This print, which is at present made from recycled plastic, might additionally change into a biomaterial and change into totally compostable. So on the finish of life, it goes again into the bottom.”

While solely a small part of this donut-shaped construction has been 3D printed to date, the workforce plans to complete and set up the entire constructing in Copenhagen within the coming years. The construction has additionally been designed for use as a quickly deployable emergency shelter.

To totally decide the sustainability advantages of the I AM MSHRM challenge, the workforce utilized Danish AM Hubs’s CO2e calculator software. Right here, the CO2 emissions of one of many construction’s arches was in contrast with that of a construction constituted of aluminum and common insulation materials. In the end, the outcomes confirmed that the I AM MSHRM construction lowered CO2 emissions by 80%.

Additionally within the area of sustainable development, Hedwig Heinsman Co-Founder & Inventive Director at Aectual and Thijs Van Hooijdonk, Supervisor Advertising Recycled Merchandise at Tetra Pak, outlined their ongoing collaboration to 3D print a collection of architectural merchandise from recycled beverage cartons.

Via this collaboration, Aectual 3D prints “totally round and customizable inside and architectural options at scale out of recycled waste supplies,” in response to Heinsman. Using recycled materials from Tetra Pak, the corporate designs and 3D print constructing interiors and exteriors, furnishings, and even sneakers for world sneaker producer Nike.

Key to this providing is that it’s fully round, with Aectual’s 3D printed architectural constructions being shredded after which re-printed on the finish of life. Given the in depth materials waste generated by the development business, Aectual and Tetra Pak’s additive manufacturing course of is alleged to supply vital potential in sustainable manufacturing.

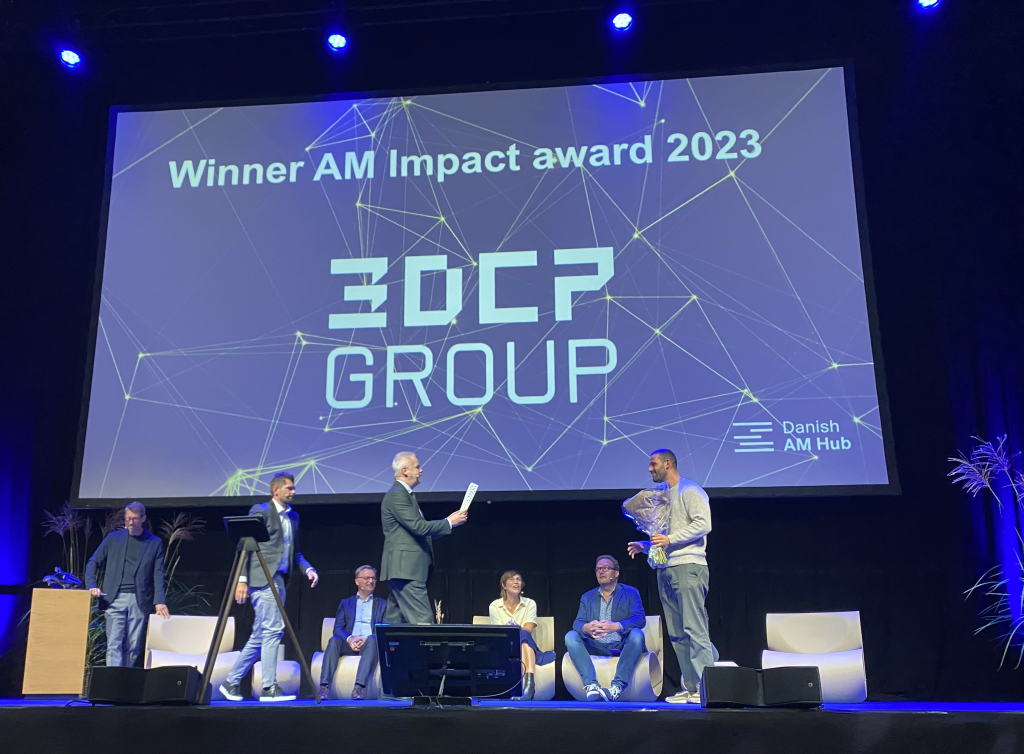

In step with this concentrate on development and structure, this 12 months’s AM Influence Award was awarded to 3D printing development firm 3DCP Group. The AM Influence award goals to recognise corporations which have “pushed the boundaries, demonstrated the capabilities of AM, and championed sustainability,” in response to Lorenzen. Along with 3DCP Group, world toy producer Lego and metal software system producer Asgaard Metals had been additionally nominated.

3DCP Group obtained the 2023 AM Influence award in recognition of their work in Lviv, Ukraine, the place the corporate 3D printed a concrete kindergarten construction. 3DCP Group’s Founder and CEO Mikkel Brich acknowledged that concrete 3D printing know-how could be utilized to “rebuild cities in a matter of weeks or months, as an alternative of it taking a few years,” with the corporate hoping to 3D print extra buildings in Ukraine sooner or later.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture exhibits the exhibition corridor at AM Summit. Photograph by way of Danish AM Hub.

[ad_2]