[ad_1]

Chinese language 3D printer producer AnkerMake, owned by electronics machine firm Anker Improvements, was based again in 2020. The corporate launched its first 3D printer, the AnkerMake M5, in 2022.

On this article we overview the M5C, the most recent addition to AnkerMake’s desktop FDM 3D printer portfolio. Based on AnkerMake, the M5C combines affordability and ease of use with high-speed, high-quality 3D printing.

Priced at simply $399, the M5C is focused in the direction of customers of all ranges, and is good for newcomers to the business. Certainly, AnkerMake’s new 3D printer is marketed as permitting customers to “make extra with much less effort.”

Key options of the AnkerMAke M5C

With 500 mm/s most 3D printing velocity and 5000 mm/s² acceleration, the M5C additionally boasts a 35 mm3/s most circulate. As such, AnkerMake claims that customers can shortly and simply 3D print components, with out compromising on high quality.

The M5C is marketed as enabling 50µm decision when 3D printing within the devoted “Precision Mode.” The M5C additionally presents “Quick” and “Regular” 3D printing profiles.

The 3D printer has additionally been designed with a 5 kg base and lowered middle of gravity, making certain decrease than 0.08 mm vibration amplitude throughout high-speed 3D printing.

The M5C presents wide-ranging materials compatibility, permitting customers to 3D print in PLA+, TPU, ABS, PETG, PA, PETG-CF, and PA-CF. That is because of the 3D printer’s stainless-steel hotend and 300℃ most nozzle temperature, which additionally presents diameter choices of 0.2 mm and 0.4 mm.

Ease of use is bolstered by the M5C’s 7 x 7 auto mattress leveling function. Right here, the 3D printer examines a complete of 49 factors on the construct plate, calculating a digital top map to make sure a great first layer initially of every 3D print.

Straightforward meeting in underneath 10 minutes

The AnkerMake M5C is designed with ease of use in thoughts, and is optimized for entry degree customers. As such, the unboxing and meeting course of for this 3D printer is very simple.

Customers want solely to connect the gantry to the bottom and tighten just a few screws to assemble the M5C. Our crew had our mannequin out of the field and assembled in lower than 10 minutes. The truth that the 3D print head is already mounted onto the gantry performs a key function in protecting the setup course of really easy.

The M5C got here very nicely packaged, shipped in a cardboard field with a beneficiant quantity of nicely reduce foam panels. This ensured that our M5C arrived in pristine situation, free from harm or any lacking components.

The 3D printer comes with a upkeep and equipment package, a bodily handbook, and an additional set of nozzles. The bundle additionally incorporates instruments wanted for setup and 3D printer upkeep.

3D Printer Packaging and Unboxing. Photographs by 3D Printing Trade.

A smooth and compact design

AnkerMake’s new 3D printer sports activities a smooth open design. The M5C’s all-aluminum enclosure covers parts such because the motors, sensors, and different important motion mechanisms, giving the 3D printer a clear and minimalist look.

Certainly, this minimalism is bolstered by the dearth of a digital interface. As a substitute, the M5C physique features a single button for pausing and resuming 3D print jobs. All different 3D printing operations are managed by way of the Ankermake app and AnkerMake Slicer.

An particularly compact 3D printer, the M5C measures simply 355 x 355 x 480 mm and possesses a complete construct quantity of 220 x 220 x 250 mm. This sizing makes the 3D printer best for desktop customers pursuing prototyping, DIY, and model-making purposes.

One other small but sensible function is the truth that the spool holder is positioned on the high of the 3D printer, reasonably than on the aspect. This leads to much less rigidity throughout 3D printing, making certain a extra constant materials circulate and minimizing the prospect that the filament will snap.

The M5C with equipment, and close-ups of the 3D print print head and movement system. Photographs by 3D Printing Trade.

AnkerMake Slicer

The M5C comes with its personal slicing software program, referred to as AnkerMake Slicer. This software program is the one slicer that may immediately management the M5C’s 3D printing course of. AnkerMake additionally offers a cellular app, which can be used to manage 3D print jobs on the M5C. The app additionally features a vary of preset fashions prepared for rapid 3D printing.

General, we discovered the AnkerMake Slicer and app to be pretty proficient. Our crew was in a position to obtain good outcomes with the offered slicer and materials profiles, while not having to make any main changes. The general design UI of the slicer was intuitive and simple to navigate, making it nicely suited to the entry-level goal market of the M5C.

The M5C is, after all, suitable with gcode, that means that customers can use third-party slicers to slice and export their 3D print recordsdata. Nevertheless, as AnkerMake Slicer is the one software program to have direct community integration with the M5C, externally sliced 3D prints can solely be uploaded by way of a USB-C stick. Customers should then use the AnkerMake cellular app to start out the 3D printing course of.

AnkerMake Slicer and cellular app interfaces. Photos by 3D Printing Trade.

Benchmarking take a look at

We started our testing with a take a look at file 3D benchy, which was downloaded from the AnkerMake app. We 3D printed two totally different benchy’s in AnkerMake PLA+ filament, utilizing each the M5C’s quick and regular modes. These fashions 3D printed in 17 minutes 40 seconds and 47 minutes, respectively.

As anticipated, the traditional velocity benchy 3D printed with the higher floor end of the 2, with fewer imperfections. This benchy had no defects across the frames or bridge areas, highlighting the M5C’s good cooling capabilities. The quick print, nonetheless, didn’t provide sufficient time for cooling, leading to some points on the underside of the roof.

3D printed benchy checks. Photographs by 3D Printing Trade.

We subsequent carried out a round trajectory take a look at to guage the M5C’s capacity to 3D print components with round sections. Our testing discovered a proportional distinction within the dimensions between the X and Y axis. The X axis is nearer to the goal dimensions, and its deviation was pretty constant. This was not the case for the Y axis.

The usual deviation of the Y-axis was additionally greater than that of the X-axis. This implies a difficulty with the M5C’s movement system. This might be solved by modifying the XYZ-steps, or by scaling the mannequin within the slicer. Nevertheless, M5C firmware configuration is at the moment inaccessible, that means that XYZ-steps can’t be modified.

Round trajectory 3D prints and measurement outcomes. Photograph and knowledge by 3D Printing Trade.

The repeatability of the M5C was additionally assessed. Right here, three totally different components (squares, hexagons, and tubes) have been 3D printed in batches of 12 every. These components have been then measured, after which in contrast towards the goal dimensions. To move this take a look at, the typical deviation needs to be underneath 0.1 mm, while the usual deviation needs to be underneath 0.05 mm.

Repeatability take a look at 3D prints. Photographs by 3D Printing Trade.

General, all three checks carried out fairly nicely in relation to the X and Y dimensions, with the typical deviations being throughout the desired vary of underneath 0.1 mm and commonplace deviations being beneath 0.05 mm. Nevertheless, discrepancies have been discovered when printing diagonally for the hexagon components. As with round trajectory, this once more suggests a difficulty with the movement system or the XYZ-steps.

Repeatability take a look at outcomes. Knowledge by 3D Printing Trade.

We subsequent carried out a bridging take a look at, designed to evaluate the M5C’s capacity to 3D print with out assist. This can be a good take a look at to guage the cooling of the 3D printer, with higher cooling usually leading to a greater bridge. The small bridge lengths begin at 5mm and attain 25 mm in increments of 5 mm. The massive bridge begins at 20 mm and reaches 60 mm in increments of 10mm.

All bridges have been efficiently 3D printed, with particularly good outcomes as much as the 20 mm size bridge. Following this size, the bridges confirmed progressively extra drooping. As most FDM 3D printers produce these defects after 15 mm, the M5C achieved above-average outcomes on this take a look at. It’s particularly spectacular that these outcomes have been achieved at 3D printing speeds of 250 mm/s.

Bridging take a look at. Photographs by 3D Printing Trade.

Tower and width checks have been additionally carried out to find out the utmost 3D printing dimensions of the M5C. The tower half achieved dimensions of 45.1 x 45 x 249.5 mm, nearly reaching the utmost construct top of the 3D printer (250 mm). The M5C additionally achieved good consistency by way of floor high quality, with no distinction from high to backside.

The width take a look at half got here in at 219.4 x 220 mm, with no warping or defects across the corners. As such, it’s clear that the M5C can efficiently 3D print near its most horizontal dimensions.

Tower and width checks. Photographs by 3D Printing Trade.

An overhang take a look at was additionally carried out to find out the 3D printer’s most printable overhang angle with out helps. The take a look at items include 6 overhangs every, growing in increments of 5 levels from 40° to 65°.

Overhangs underneath 55° 3D printed fairly nicely, nonetheless the 60° and 65° overhangs failed with noticeable gaps between layers. Because the components have been printed at the usual 250 mm/s velocity, we view these outcomes as excellent. Slower speeds would enable for extra cooling, enhancing the overhangs.

Overhang checks. Photographs by 3D Printing Trade.

We subsequent carried out a retraction take a look at, the outcomes of which have been fairly spectacular. There was no stringing or artifacts current, aside from some wisping on the high. That is because of the M5C scorching nozzle temperatures and the direct drive mechanism, which allow extra management over filament extrusion.

We additionally carried out our in-house 3D Printing Trade (3DPI) benchmarking take a look at, which incorporates quite a lot of totally different checks in a single mannequin. 3D printed in PLA+. This take a look at was repeated thrice utilizing the M5C’s regular, precision and quick profiles. The M5C carried out nicely right here, besides throughout the accuracy take a look at.

The primary variations between these three 3D prints associated to overhang functionality, and the flexibility to 3D print with good unfavorable precision. Surprisingly, the quick profile achieved the very best unfavorable precision end result, able to 3D printing a 0.15 mm unfavorable precision, in comparison with 0.2 mm achieved by the opposite two profiles. The one situation we encountered with the quick 3D print have been poor overhang functionality and floor high quality, with this profile leaving seen cavities on the outer layer.

The precision take a look at carried out the very best by way of overhangs. This was anticipated, because the extruded filament was uncovered to the cooling fan for longer in comparison with the quicker 3D prints.

3DPI checks for the traditional, quick, and precision profiles. Photos and knowledge by 3D Printing Trade.

A small and exact components take a look at was additionally carried out to find out if the M5C can print a two-part purposeful nut and bolt mannequin with very small dimensions and tolerances. The 3D printer carried out nicely right here, fabricating a component with no interference, even at a 0.2 mm layer top.

Small and exact components take a look at. Photographs by 3D Printing Trade.

Utility checks

Our crew additionally carried out plenty of checks to evaluate how nicely the M5C handles totally different supplies and real-world use instances.

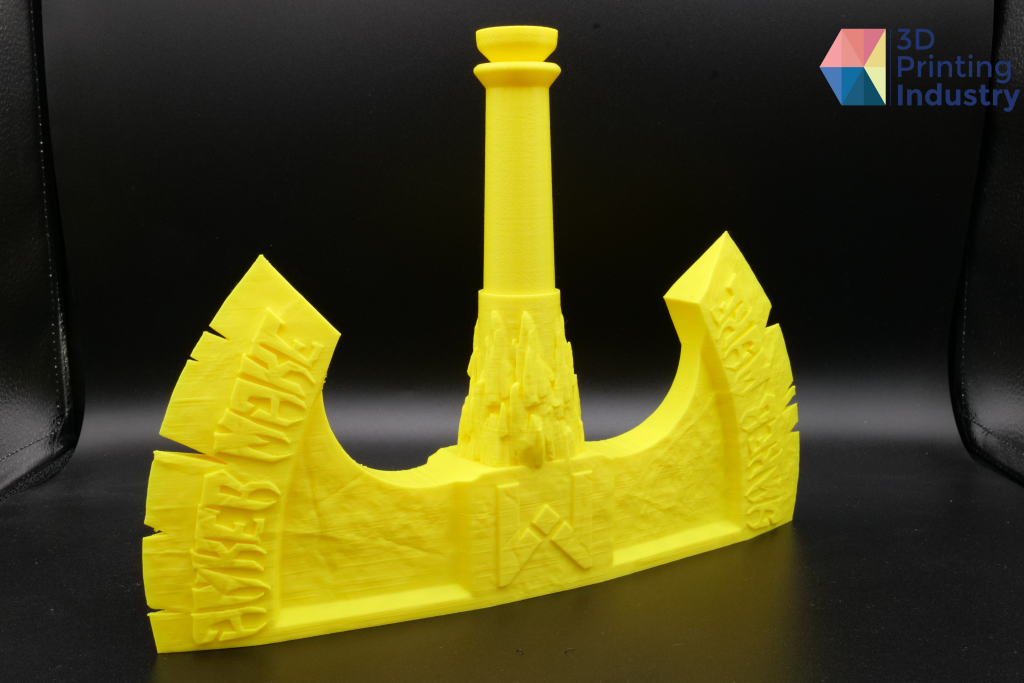

We first 3D printed an extendable ax mannequin, taking 10 hrs and 45 minutes within the 3D printer’s regular mode. The floor high quality of this half was fairly spectacular, nonetheless there have been sections the place the 3D printer traveled exterior the mannequin’s 3D printing zone. This created skinny artifact strains on the floor of the half.

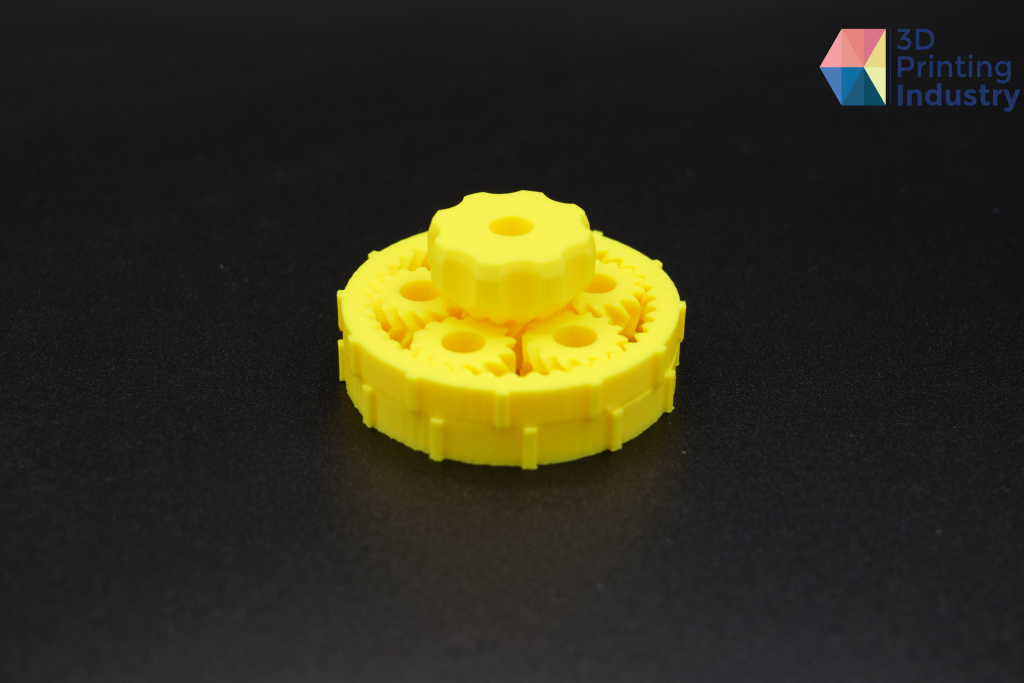

We subsequent 3D printed a planetary gear utilizing PLA, a purposeful half which incorporates numerous excessive tolerances. Once we first previewed the mannequin at 0.20 mm layer top, the hole between the rings was not sufficiently distanced by the slicer. We subsequently lowered the layer top in order that the slicer would depart a niche. After 3D printing, the mannequin fused and required some manipulation to free the gears. General, the standard was good, with the gear system shifting easily with no extra friction.

Once more utilizing PLA, we 3D printed two typical hobbyist miniature fashions utilizing the 0.2 mm diameter nozzle. These components have been spectacular, each possessing a easy and constant floor end with no noticeable ringing.

Figurine and Citadel fashions. Photographs by 3D Printing Trade.

A Voronoi tower was additionally 3D printed in PLA+ to evaluate the M5C’s capacity to deal with detailed prints with many overhangs. This mannequin was 3D printed thrice utilizing every profile (quick, precision, and regular).

The M5C 3D printed these fashions with none failed helps or seen defects. All the element has been preserved in all three profiles, with the general high quality being very for every excessive. This showcases the M5C’s capacity to 3D print intricate fashions at excessive speeds, with out sacrificing an excessive amount of on high quality.

Voronoi tower in 3 profiles (quick, precision and regular). Photographs by 3D Printing Trade.

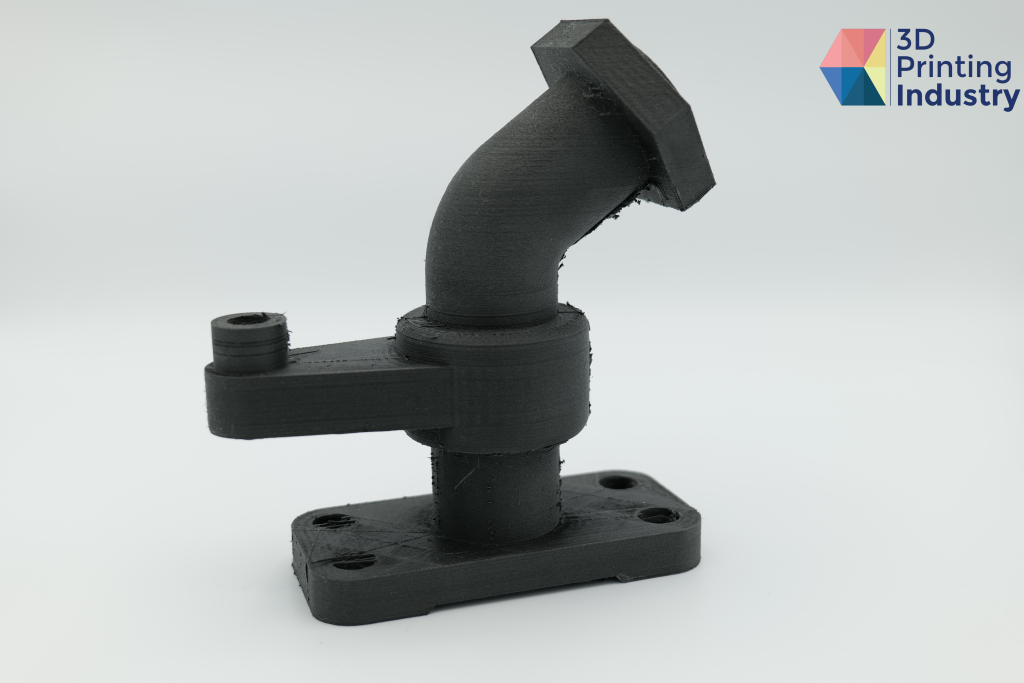

Lastly, we 3D printed a purposeful pipe fixture utilizing Nylon-Carbon Fiber, a composite materials. To print this half, we used a hardened metal nozzle with a 0.4 mm diameter.

This half 3D printed very nicely on the primary strive, utilizing the default profile that comes with AnkerMake slicer. There was some stringing that was seen whereas printing the half, however this was simply cleaned after some publish processing, and didn’t considerably influence the 3D print high quality.

We have been impressed by the M5C’s composite materials compatibility, as this expands the 3D printer’s buyer base past hobbyists to the intermediate market.

Closing verdict

General, the M5C stands out as a cheap and user-friendly FDM 3D printer that provides good 3D print velocity and high quality. The 3D printer is optimized for learners, and presents an accessible entry level into desktop 3D printing. Its 300℃ nozzle permits for wide-ranging materials compatibility, additional increasing the utility of this 3D printer for intermediate customers.

The reliability of the M5C is one thing that actually stood out throughout this testing course of. Certainly, we didn’t encounter a single failed 3D print or any sensor errors. What’s extra, the M5C persistently delivered on its marketed capacity to provide high-quality components.

The M5C’s capacity to persistently and efficiently full 3D prints units it aside from many different 3D printers available on the market at this value level, making it a superb selection throughout the desktop house.

The M5C’s construct high quality additionally impressed, with its strong and well-constructed body bolstering its reliability and enhancing its aesthetics. Furthermore, this spectacular construct high quality extends to the 3D printers inside parts and supplies, making certain sturdiness and longevity.

In the end, customers in search of a 3D printer that mixes efficiency, reliability, and aesthetics will discover the M5C to be a superb selection. We will affirm that AnkerMake’s M5C offers very strong 3D printing efficiency with not one of the trouble, making it a perfect entry-level FDM 3D printer.

| 3D Printing Know-how | FDM (Fused Deposition Modeling) |

| Construct Quantity | 220 x 220 x 250 mm |

| 3D Printer Dimensions | 466 x 375 x 480 mm |

| Most 3D Print Pace | 500 mm/s |

| 3D Print Acceleration | 5000 mm/s² |

| Most Circulation Fee | 35 mm3/s |

| Most Nozzle Temperature | 300℃ |

| Heated Construct Plate Temperature | As much as 100℃ |

| Marketed Filament Compatibility | PLA+, TPU, ABS, PETG, PA, PETG-CF, PA-CF |

| Layer Thickness | 0.1 – 0.25 mm |

| Nozzle Diameter | 0.2 mm & 0.4 mm |

| Filament Diameter | 1.75 mm |

| Extruder Amount | 1 |

| Physique Materials | Aluminum Physique |

| Hotend | All Metallic Hotend |

| Gross 3D Printer Weight | 12.8 kg |

| Slicer Compatibility | AnkerMake Slicer, Cura, PrusaSlicer |

| Connectivity | USB-C, WiFi, Bluetooth |

| File Output | .gcode |

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits the AnkerMake M5C. Photograph by 3D Printing Trade.

[ad_2]