[ad_1]

World industrial 3D printer producer INTAMSYS not too long ago partnered with main 3D printing supplies provider KEXCELLED to supply its FDM/FFF 3D printing options for the Automotive Division of SIKA in China.

This mission marks a major milestone within the automotive business, and has seen notable time and price financial savings of as much as 90% for SIKA’s automotive prototyping and growth levels.

“In contrast with conventional injection molding strategies, INTAMSYS 3D printing has helped us cut back time and price by 80%-90% for the prototype growth, giving a lift to fast iterations and important adjustments wanted to be made with tight timelines,” commented Mr. Chen from Sika China’s Automotive Division.

INTAMSYS and the growth of additive manufacturing

Within the wave of Business 4.0, 3D printing continues to alter the manufacturing panorama. As an rising manufacturing know-how within the automotive business, 3D printing has injected new vitality, particularly within the points of fast prototype trial manufacturing, useful prototype verification, tooling and jigs & fixtures. It additionally assists with the manufacturing and utility of spare components for personalized, discontinued or small batch automobiles.

Beneath the pattern of electrification and good manufacturing for cars, together with the need and product differential client upgrades enable, clients are attaching extra significance to inside and exterior equipment. This has led to a rising pattern of diversification, personalization, and customization to fulfill diversified buyer calls for.

Possessing wealthy expertise within the automotive business, INTAMSYS has extensively utilized industrial 3D printing know-how to automotive inside and exterior equipment. These embody, amongst others, personalized bumpers, steering wheel take a look at items, racing automobile components, and tail emblem fixtures.

In contrast with conventional injection molding strategies, INTAMSYS FDM/FFF 3D printing has helped shoppers within the automotive business cut back time and price by 80%-90% for his or her prototype growth, giving a lift to fast iterations and important adjustments wanted to be made with tight timelines.

The collaboration with SIKA and KEXCELLED

As an automotive element provider able to offering a whole set of adhesive, shock absorption, sealing, and structural enhancement options, SIKA helps OEM shoppers create automobiles that are lighter, stronger, safer, quieter, and extra eco-friendly.

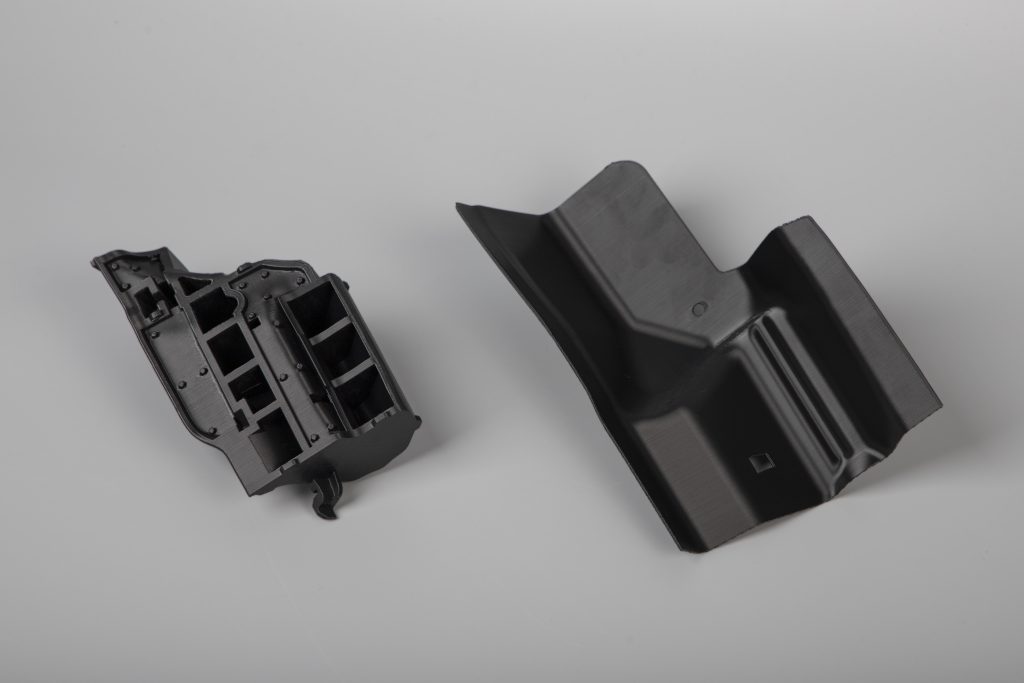

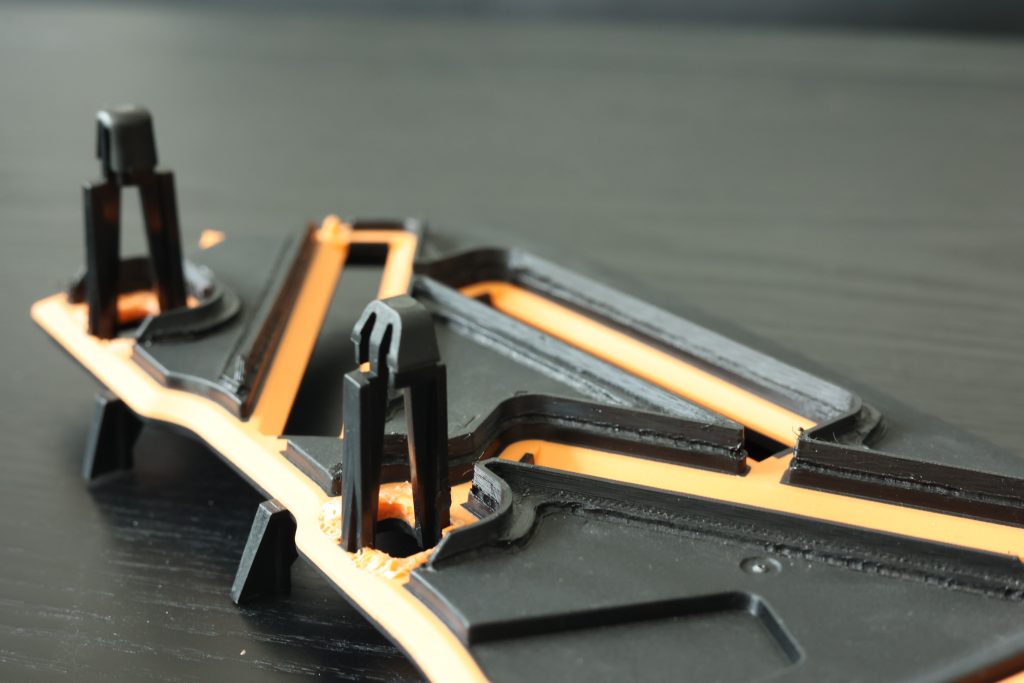

In the course of the manufacturing and verification strategy of their prototypes, the parts 3D printed by INTAMSYS’ FUNMAT PRO 410 have been bonded with SIKA EVA eco-friendly plastic foam supplies. EVA foam supplies stuffed the gaps between the printed parts and the bodywork, forming a sturdy construction that not solely ensured the required stiffness of the car physique, but in addition offered shockproof, sound insulation, and noise discount.

In the course of the collection of 3D printing supplies, PAHT K7 from KEXCELLED stood out due to its traits of excessive rigidity, excessive efficiency, and ease of use.

This materials possesses a fracture elongation of 21-25%, with good toughness and wonderful affect power. PAHT K7’s elastic modulus ranges from 4600 to 4800Mpa, demonstrating excessive rigidity and noteworthy load-bearing capability. As well as, it has low creep efficiency, is just not liable to deformation, and maintains good accuracy. Thanks to those traits, components 3D printed utilizing KEXCELLED PAHT K7 constantly meet lots of the numerous necessities for automotive parts.

Wanting previous the uncooked print off the construct tray, the sound adhesion property of the fabric permits it to simply type composite buildings and parts for particular capabilities with different supplies. This permits lots of the necessary attributes talked about earlier, reminiscent of sound insulation, noise discount, and shockproofing.

The KEXCELLED PAHT K7 filament, with its superior properties, has extraordinarily excessive necessities for the 3D printing potential of the gear. 3D printers utilizing PAHT K7 want to handle the water absorption impact of nylon, whereas assembly the 3D printing temperature necessities.

As an industrial-grade twin nozzle high-temperature 3D printer, the INTAMSYS FUNMAT PRO 410 encompasses a format printing dimension of 305 * 305 * 406mm, and is supplied with wire sealing and drying know-how and multi-material protection potential. The FUNMAT PRO 410 can 3D print PA engineering plastics with extraordinarily excessive accuracy and high quality, producing detailed and high-quality prints which precisely reproduce the design mannequin of automotive parts.

Primarily based on the optimization and strict testing of the KEXCELLED PAHT K7 materials course of parameters, INTAMSYS has maximized its efficiency benefits, serving to SIKA to rapidly and repeatedly confirm their design whereas additionally altering plans of the BIW cavity noise isolation and structural enhancement parts. This significantly reduces the danger and price of verifying and altering molds. Notably, the 3D printed parts are instantly used for prototype verification, shortening each the time for element design modification and your complete car growth cycle.

INTAMSYS’ rising additive manufacturing choices

Totally different purposes within the automotive business have additionally put ahead excessive necessities for supplies. INTAMSYS gives industrial 3D printing options protecting completely different supplies, together with many with high-performance attributes used to construct fastened units, gaskets, busbars and different parts in racing automobiles. INTAMSYS know-how can be optimized for composite supplies used for turbofan engine parts, and engineering supplies used for air-con filter cowl plates and steering wheel trial components.

INTAMSYS collaborates carefully with clients within the automotive business chain reminiscent of Porsche, Tesla, BMW and Toyota. The corporate’s key purpose is to empower the event of electrification and good manufacturing within the automotive business.

INTAMSYS, as a world main high-tech firm offering FDM/FFF 3D printing options with high-performance supplies and industrial direct additive manufacturing options, has at all times devoted itself to selling additive manufacturing as an modern methodology for industrial creation. Sooner or later, INTAMSYS is about to pursue extra in-depth partnerships with main enterprises to collectively discover the potential of business 3D printing in a wider vary of purposes.

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture exhibits a 3D printed SIKA physique in white. Photograph through INTAMSYS.

[ad_2]