[ad_1]

Two metallic additive manufacturing techniques from Velo3D are headed to Italian aerospace firm Avio S.p.A to assist the event and manufacturing of its house propulsion techniques.

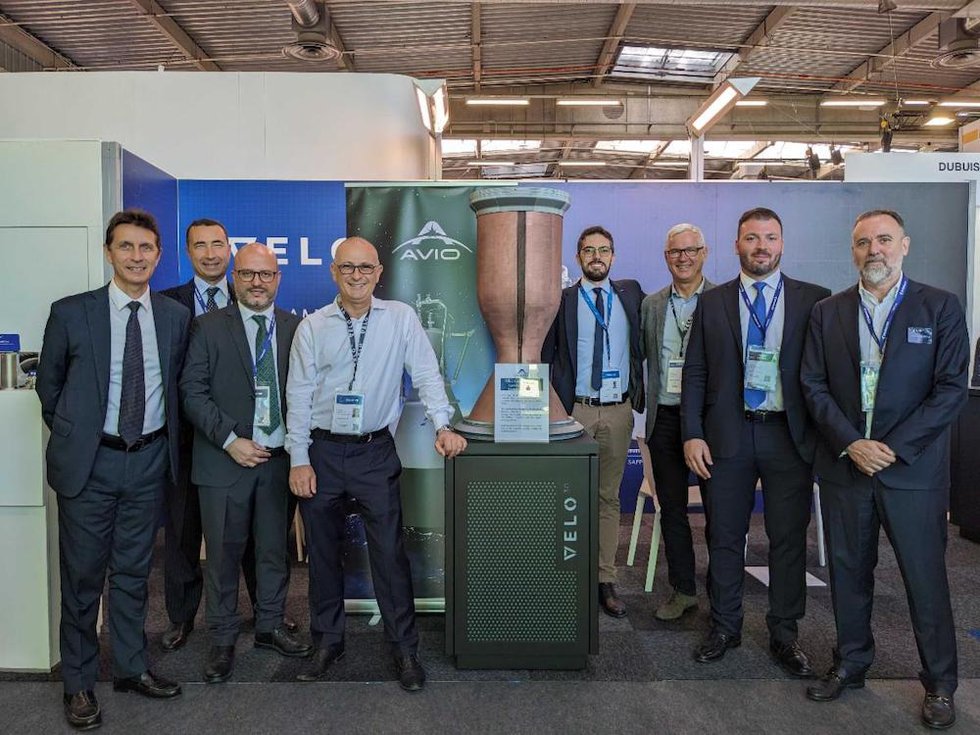

The acquisition, which was introduced through the Paris Air Present, features a Sapphire XC 1MZ 3D printer and an authentic Sapphire system, each calibrated to supply elements in nickel-based alloy with excessive energy and corrosion resistance at excessive temperatures. The machines are mentioned to have been chosen for his or her capability to supply giant metallic elements with optimised geometries.

“Avio is likely one of the main house corporations in Europe and we’re thrilled to associate with them of their pursuit of groundbreaking propulsion techniques,” mentioned Benny Buller, Founder and CEO of Velo3D. “They work with a few of the most progressive corporations and businesses in Europe and around the globe to offer them with the expertise they should attain house. The Sapphire XC 1MZ will assist Avio additional speed up the event of its propulsion techniques and contribute to the continued transformation of the house business.”

Velo3D’s expertise is already being deployed by plenty of new house and aerospace corporations together with SpaceX, Launcher and Increase Supersonic due to its capability to supply giant complicated metallic elements, “support-free“. Its Sapphire XC 1MZ 3D printer incorporates a print quantity of 600 mm in diameter and 1,000 mm in top, whereas its authentic Sapphire can manufacture elements inside a quantity of 315 mm in diameter and 400 mm in top.

Avio has been working within the aerospace business for over 120 years and is now targeted on propulsion techniques and ‘making house extra accessible and inexpensive.’ Via its Vega household of launch autos, Avio has helped to launch institutional, governmental, and business payloads into orbit.

[ad_2]