[ad_1]

Due to 3D printing, manufacturing has been graced with diminished prices, materials waste, and sooner design iteration, particularly within the steel AM sector.

Nevertheless, as calls for skyrocket, the minor constraints of AM, together with limitations in attaining sure tolerances and options in important purposes, have gotten extra noticeable. Excessive demand drives the search for cost-effective options, albeit generally on the expense of high quality, urging a glance into post-processing strategies for refining AM components.

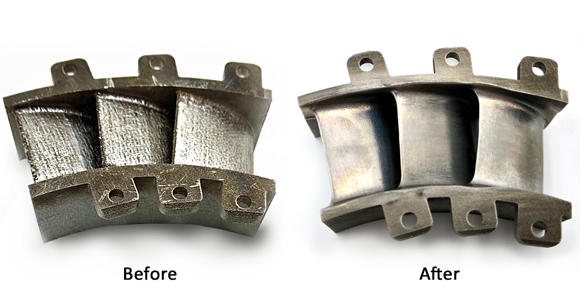

Enter Pulsed Electrochemical Machining (PECM), a novel materials removing course of spotlighted by Kirk Gino Abolafia from Voxel Improvements. Not like standard strategies, PECM doesn’t depend on friction or warmth. It employs electrochemistry to dissolve workpiece materials, attaining superfinished surfaces, small options, and excessive repeatability. That is significantly helpful on steel AM components, making it a promising secondary machining and post-processing approach.

PECM shines in coping with high-volume steel AM components by considerably enhancing floor high quality and determination whereas decreasing manufacturing prices. As an illustration, it might slim down the wall thickness of AM components to lower than 0.05 mm, a feat exhausting to realize with AM alone. Furthermore, its non-contact, non-thermal nature permits machining of delicate areas with out instrument put on, making PECM a extremely repeatable course of.

Notably, PECM’s capabilities lengthen to important aerospace and medical machine elements, showcasing its potential in enhancing efficiency, sturdiness, and security of AM merchandise, particularly in high-stress or temperature flux environments.

PECM stands out as a complementary answer to AM, addressing floor irregularities and have dimension points, guaranteeing steel AM components meet the stringent necessities of important purposes whereas preserving manufacturing prices in test.

Supply: metal-am.com

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.

[ad_2]