[ad_1]

Because the semiconductor business strikes to next-generation 3D architectures, the necessity intensifies for course of management options that may scale back the time to ramp a know-how to production-level yields. Gate-All-Round (GAA) transistors, EUV lithography, and scaled reminiscence units all current difficult necessities for detection of defects buried inside 3D constructions. As vital dimensions shrink, these defects can method single-digit nanometers in measurement, or just a few atoms thick.

Chipmakers use two instruments to search out and management manufacturing defects: optical inspection to detect potential defects on the wafer, adopted by eBeam evaluate to characterize these defects in additional exact element. Optical inspection and eBeam evaluate are complementary – collectively they ship an actionable pareto that engineers can use to optimize yield and guarantee sooner time-to-market.

A key problem dealing with eBeam defect evaluate on the most superior nodes is the power to distinguish the true defects from the false alarms offered from the optical inspection programs, whereas sustaining the excessive throughput essential for quantity manufacturing.

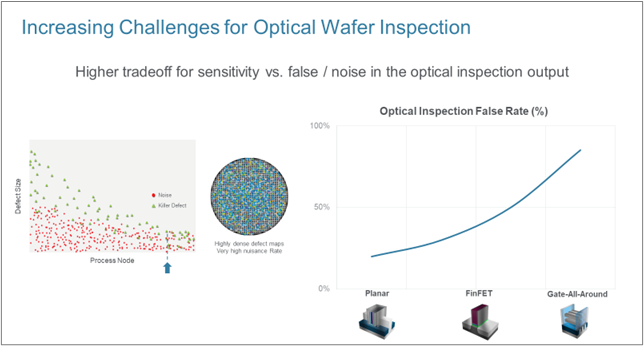

The eBeam evaluate course of has grow to be rather more difficult as transistors have moved from planar to FinFET and now GAA. The “false fee” – when optical inspection flags one thing that’s not a real defect – greater than doubles with the GAA constructions. Defects are smaller and killer defects are harder to tell apart from noise with GAA and superior recollections. The defect maps created after optical inspection grow to be denser, with a considerable amount of nuisance (>90%), to be able to seize the required defects of curiosity (DOIs). With such a excessive nuisance fee, it turns into practically unattainable to ship an actionable pareto with sufficient DOIs to realize statistically important course of management. To compensate for the excessive variety of candidates in inspection, course of management engineers want defect evaluate programs that may ship much more samples than right this moment’s typical benchmark of a number of a whole bunch of DOI candidates.

Deep Studying for Defect Classification

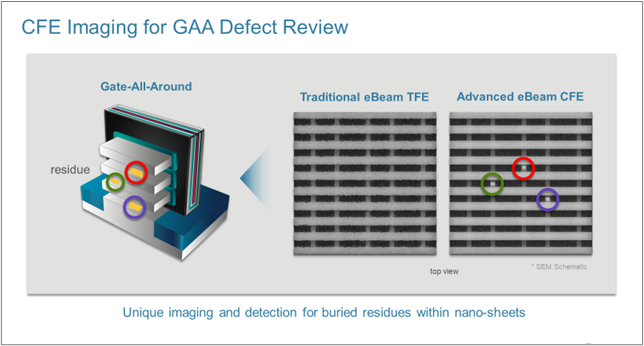

Utilized Supplies is the main supplier of eBeam defect evaluate programs. In 2022, we launched our “chilly discipline emission” (CFE) know-how, a breakthrough in eBeam imaging that allows chipmakers to higher detect and picture nanometer-scale, buried defects. We at the moment are extending this know-how to deal with the elevated sampling necessities of the excessive false alarm charges (“Excessive FAR”) of superior logic and reminiscence.

When mixed with the usage of back-scattered electrons that allow high-resolution imaging of deep constructions, CFE know-how permits higher throughput whereas sustaining excessive sensitivity and backbone in contrast with previous-generation thermal discipline emission (TFE) sources – enabling sub-nanometer decision for detecting the smallest buried defects.

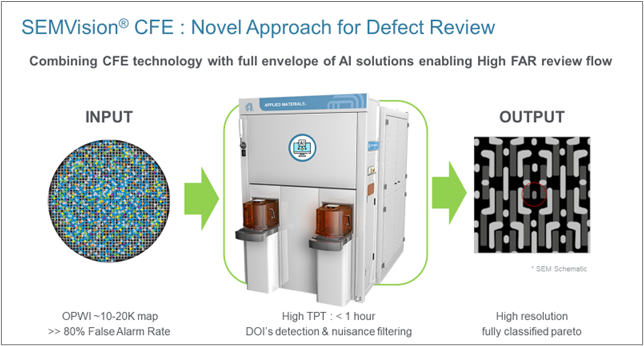

Utilized is now combining the usage of CFE with deep studying AI know-how for automated extraction of true DOIs from the false “nuisance” defects. In lots of circumstances, the precise DOIs are solely 5 p.c or much less of the evaluate candidates. The deep studying community is constantly educated with information from the fab and kinds the defects right into a defect distribution together with voids, residues, scratches, particles and dozens of different defect varieties. Defect extraction is extremely correct, with practically 100-percent accuracy.

3D Units Want 3D Course of Management

Using Utilized-developed AI to allow automated DOI extraction and classification is a brand new software. In a single use case, the eBeam system thought of roughly 10,000 defect candidates of a GAA system. Whereas conventional defect evaluate may have the ability to pattern this many candidates, the brand new CFE with AI defect evaluate system delivers a lot higher sensitivity and better throughput, dealing with 10,000 candidates in lower than an hour. Furthermore, the AI-enabled in-line detection, filtering and classification system can classify 4X as many DOIs into particular varieties. Combining CFE know-how with a full envelope of AI options makes it doable to take care of the excessive false alarm charges for 3D constructions offered by the wafer inspection programs. CFE presents the required sensitivity to picture the difficult defects, at larger throughputs in contrast with conventional TFE programs. Subsequently, with the assistance of AI, the required DOIs are captured with excessive accuracy, filtering out nuisances.

As 3D units are being deployed in manufacturing, Utilized has developed defect evaluate know-how that may pattern 10,000 – 20,000 places per hour, deal with false-alarm charges exceeding 90 p.c, and classify the defect varieties offered to statistical course of management options. This revolutionary defect evaluate method is being efficiently demonstrated at main logic and reminiscence chipmakers. Primarily based on the suggestions to date, we see a robust pull from clients as they handle the Excessive FAR problem.

Senior Product Advertising and marketing Supervisor

Utilized Supplies

[ad_2]