[ad_1]

3D Printing Trade attended DEVELOP3D LIVE in Coventry, UK, to listen to from consultants in superior design software program.

“Design software program itself has at all times been a bottleneck computational design can open up the center of what’s potential,” believes Bradley Rothenberg, CEO of nTop. nTop supplies superior engineering software program, together with instruments for topology optimization and generative design.

Generative design is an method that begins the place different design strategies finish. The aim is specified within the type of constraints, and through an iterative course of, designs are generated with the framework that may attain that aim. Topology optimization is extra generally used later within the design cycle. Person-specified constraints are coupled with an algorithm to search out the optimum steadiness of supplies.

Rothenberg joked that even his firm, beforehand often known as nTopology, has been optimized.

Are the businesses on this article main the business? Nominate now within the 2023 3D Printing Trade Awards.

nTop CEO Expounds on Superior Design’s Future

“We will manufacture extra advanced components than we will design,” Rothenberg asserted. Or drawing on a quote from a previous presentation, “Increasing the artwork of what’s potential.”

In response to Rothenberg, the crux of the difficulty lies within the outdated “digital instrument stack” that has didn’t maintain tempo with cutting-edge digital manufacturing capabilities. “You may make extra advanced shapes [with additive manufacturing], however our digital instrument stack was by no means designed for that.” Rothenberg contended that regardless of the leaps in digital innovation, many rules partly engineering “don’t look lots totally different than what we had been doing within the Eighties with drafting tables.”

Presenting an instance of a Grundfos industrial pump, Rothenberg claimed it would look just like their ’90s counterparts. Nonetheless, what has modified is the elevated integration of electronics and software program. The answer, Rothenberg believes, could lie within the emergent idea of generative design, which distinguishes the logical from the bodily processes of making a component. This method permits designers to “outline the necessities or the purposeful necessities upfront” and lets the software program produce the mandatory system.

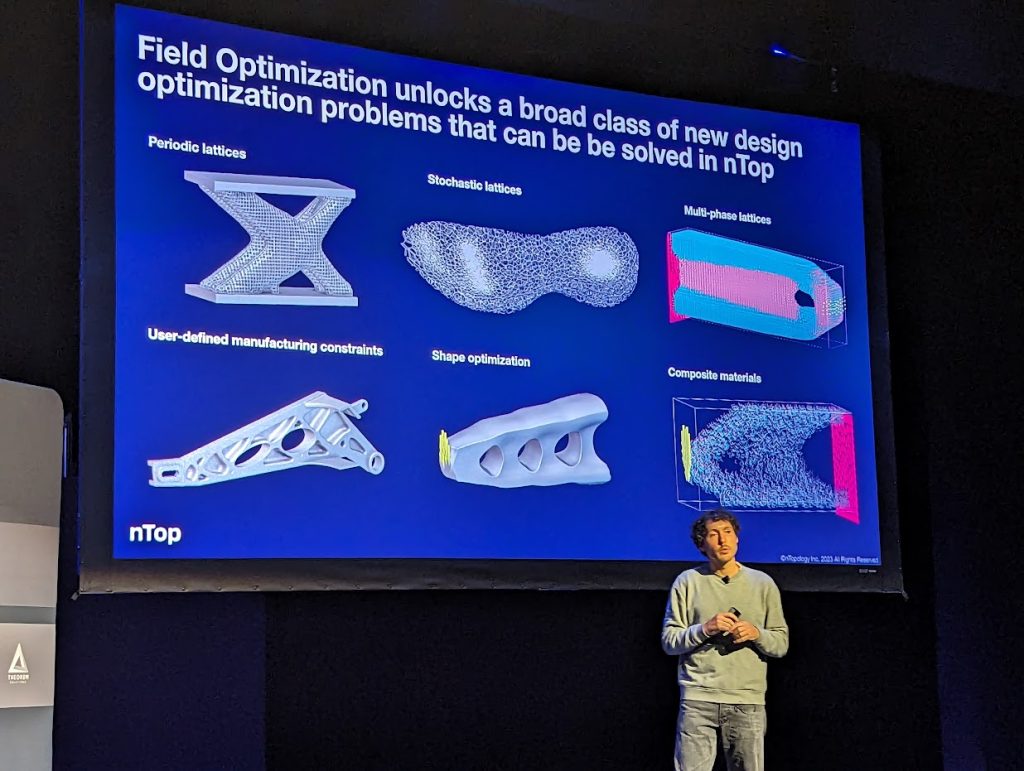

nTop’s “field-driven design functionality” integrates real-world physics straight into design parameters, enabling designers to create fashions grounded in actuality. Automation permits groups to “rerun, reuse, and share” designs, fostering collaboration and effectivity.

Rothenberg factors out how their modernized methods addressed complexity challenges. “In software program techniques, we now have model-based design, steady integration, and steady deployment. However the present toolset [for mechanical design] was by no means constructed for that,” Rothenberg says. He makes use of the time period ‘generative design’ as a potential answer, emphasizing the necessity to differentiate between logical and bodily processes.

Rothenberg described nTop’s expertise: “With implicit modeling, you’re feeding necessities into it, these necessities are being run in a pocket book, you’re composing these blocks collectively.” This course of, leveraging a differentiated tech stack, permits for considerably extra intricate half design and improved efficiency.

The CEO described an modern use case: an aerospace warmth exchanger that guarantees a 5% discount in quantity, superior warmth switch, and enhanced strain drop in comparison with conventional fashions. This warmth exchanger, developed in collaboration with the Air Power Analysis Lab, goals to rectify persistent points in Blackhawk helicopters, the place conventional warmth exchangers usually fail.

One other standout venture comes from Life Enabled, which produces “the world’s most superior prosthetics” in Guatemala. Leveraging nTop’s expertise, they’ve expedited the design course of for custom-made prosthetics, guaranteeing a turnaround of lower than per week. Rothenberg additionally drew consideration to Ocado’s collection 600 robotic, hinting at its transformative potential for warehouse operations.

The Way forward for Computational Design and 3D printing

Rothenberg was later joined on stage for a panel dialogue round computational design, moderated by SJ from organizers Develop3D.

The business consultants weighed in on the long run and software of computational design.

Moritz Valentino Huber of software program developer Hyperganic highlighted the success of dental aligners as a client product that has significantly benefited from computational design and additive manufacturing. He additionally alluded to the necessity for a mentality shift for industries to harness its potential absolutely.

nTop’s CEO underscored the worth of customization in merchandise resembling dental aligners. He highlighted the transformative influence of computational design on system-level efficiency, asserting, “What we’re lacking proper now could be what’s the influence of the computational design of a component and the way that impacts the general system’s stage efficiency.”

Alice Smart, a Analysis Engineer from the Manufacturing Expertise Centre (MTC), urged individuals to look past additive manufacturing and think about a extra complete system-level method. She talked about, “There’s been quite a lot of AI and machine studying growth in each Siemens and SolidWorks. It’s about interrogating [machine learning] fashions [to see] can I mix these two issues whereas doing additive manufacturing, like half consolidation?”

General, the consensus among the many consultants is that computational design holds transformative potential throughout numerous industries, and the actual problem lies in harnessing it successfully at a system-wide stage.

Limitations to Computational Design Adoption

Discussing the hurdles confronted by the computational design sector, Alice Smart, at MTC cited “standard and historic considering” as main obstacles. She emphasised that though new startups are revolutionizing design concepts, these improvements face resistance, particularly from conventional industries reliant on time-tested strategies and instruments. “There are such a lot of limitations to entry on issues like aerospace, when it comes to standardizing supplies, introducing something new that’s not traditionally been validated,” she famous. Smart careworn the significance of schooling, case research, and partnerships with massive firms.

Alex Pluke, GM and CTO at software program developer Additive Movement, highlighted the monetary features, stating, “It’s extra than simply legacy considering. It’s, the place is the cash?” He talked about the numerous shifts in inventory market investments attributable to expertise adoption and identified that applied sciences like AI have obtained large investments attributable to their newfound accessibility.

Rothenberg, CEO of nTop, instructed that the crucial bottleneck is individuals’s mindset and the enterprise case supporting improvements. He known as for business influencers to push the boundaries and present engineers the realm of potentialities.

Moritz Valentino Huber of Hyperganic careworn the “information hole” between totally different phases within the worth chain, with design, simulation, and manufacturing usually not in sync.

Mechanical-Software program Convergence: Future Integration

“How do the necessities feed between the 2 disciplines?” queried Rothenberg, emphasizing the incongruity of putting in box-like electronics in curved airplane constructions and the necessity for a extra cohesive design method. “It’s not simply concerning the pace of design,” Rothenberg elaborated, “however understanding how one change impacts the entire system. The faster you perceive that, the higher you may get to a desired outcome.”

Alex Pluke, GM and CTO at Additive Movement, touched on the evolution he witnessed: “You’re beginning to see this convergence between phases and scales,” referencing his observations from a latest journey to Israel and the creating panorama of 3D printed digital techniques. But, he additionally underscored the challenges of interdisciplinary collaboration, rhetorically asking if digital and chemical engineers, for instance, at all times “use the identical language” and have “the identical priorities and targets.”

Matt Shomper, Founding father of LatticeRobot, posited a shift within the method to conventional CAD techniques. He believes the following frontier in computational design goes past creating tangible merchandise, encompassing a broader techniques engineering scope. “Programs Engineering is extra than simply providing you with a bodily product; it’s multifaceted. It’s this multiphysics evaluation of your design area to get to an answer,” Shomper stated. He highlighted the potential of CAD instruments for advanced information manipulation, successfully bridging the realms of design and information processing.

Shomper emphasised, “Talking as anyone who comes from medical gadgets, there’s already been penetration into the market.” He cautioned in opposition to underestimating the challenges confronted in these sectors by noting, “When you begin moving into any regulated market by any means… there’s a major hurdle that must be overcome.”

SJ, the panel’s moderator, resonated with these sentiments, sharing private experiences of using computational instruments like nTop for unconventional information processing throughout grad college. This enterprise generally led her “down a rabbit gap.”

The consensus leaned in the direction of a future the place there’s an inevitable merger of mechanical design with the software program realm, enabling merchandise and options which can be each environment friendly and efficient.

Altering Legacy Mindsets in Tech

The main focus turned to the challenges of adjusting legacy mindsets within the technological subject.

Matt Shomper of LatticeRobot emphasised that whereas he’s usually cynical about humanity’s openness to vary, he believes presenting information is paramount. He stated, “The very first step is to again no matter you say with information.” Many are naturally suspicious of unfamiliar applied sciences, and showcasing compelling information can provoke a dialogue.

Bradley Rothenberg pointed to examples of innovation, like Joby Aviation, which have successfully adopted 3D printed elements of their check flights. He highlights the significance of working inside current techniques however pushing their boundaries. Rothenberg cited an instance elsewhere occasion the place a software program engineer leveraged GitHub, a free instrument, to satisfy FDA {qualifications} as a substitute of conventional PLM techniques.

Alex Pluke from Additive Movement drew consideration to the secrecy surrounding the business’s modern applied sciences. He acknowledged that whereas it’s comprehensible firms wish to defend their mental property, there’s a have to discover a steadiness to encourage innovation. He additionally highlighted the significance of human-driven design considering, stating, “I believe simply as an overarching level once we’re taking a look at issues like AI and computational engineering… these instruments can empower individuals.”

Alice Smart mirrored Shomper’s sentiments on skepticism in the direction of new expertise, evaluating it to the gradual acceptance of electrical vehicles.

In abstract, the panelists agreed that whereas skepticism in the direction of new applied sciences stays, there’s a rising pattern towards adopting superior tech options. The bottom line is to current compelling information, assume innovatively inside current frameworks, and draw inspiration from business leaders whereas navigating the steadiness between secrecy and shared information.

Alice Smart touched on the complexities of generative design and topology optimization, emphasizing the necessity for clear targets. She stated, “Generative design… requires you to have some aim in thoughts.” Later, she mentioned how AI instruments would possibly higher seize and codify design necessities.

The DEVELOP3D LIVE panel supplied a notable discourse between customers and builders of superior design software program. Each technical developments and sector-specific constraints will form future trajectories in expertise adoption.

Featured picture reveals Develop3D Dwell panel on Computational Design. Pictures by Michael Petch.

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

[ad_2]