[ad_1]

And we’re again! At present we’re going to wrap up our PCB design sequence with looking on the extra artistic, customizable points of design. This entails altering up our board form, importing photographs on to the silk display screen, and studying easy methods to add mounting holes for issues like keyrings or stand-offs. That is my favourite kind of board design to do, so let’s get this ball rolling!

In case you missed it: you’ll want to take a look at the remainder of the sequence to learn to go from a schematic diagram to a THT or SMT board!

Parts

Alright, we’re going to maintain our circuit easy and give attention to the board, so right here’s an inventory of the elements I used with mine for those who’d wish to reference these:

- Battery: C964831

- Button: C10852

- Resistor: C101329

- LED: C2286

Since we’ve already lined making a schematic diagram and putting and connecting parts on the board, we’ll skip going over that step right here. In case you missed that data, or want a refresher, you’ll want to take a look at the earlier EasyEDA weblog posts; for my design I went the SMT route however you’ll be able to, in fact, use THT for those who’d want!

Import a .DXF for the Board Define

The very first thing you’ll have to do is locate some form that you really want your board to be: the easier the picture, the simpler will probably be to get a top level view from it. Then, take that picture into an enhancing software program of your selection; I exploit Inkscape because it’s free to obtain and we don’t want plenty of bells and whistles for this, however something that lets you generate a .DXF of your define will do!

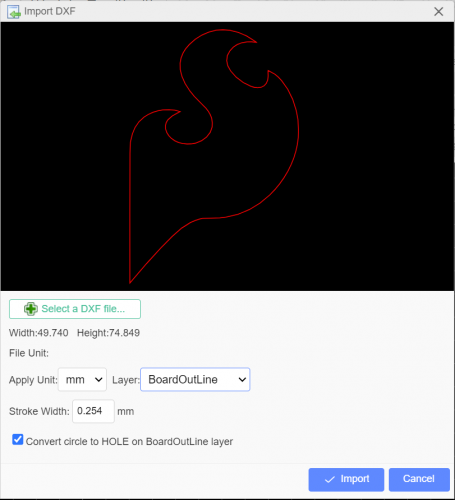

As soon as that’s able to go, generate your PCB and delete the default board define. Then, go as much as File → Import → DXF… and choose your file. A preview of the file will popup, with a measurement description beneath the ‘Choose a DXF File…’ button; one factor to remember is that JLCPCB has a further cost for boards exceeding 100x100mm and the scale might be imported out of your DXF file. I wished mine to be keychain sized, so I made certain to notice that when creating the DXF of the define I wished (which seems vaguely acquainted, don’t it?). With the scale good to go, all that’s left is to make sure that our layer is about to ‘BoardOutline’ within the dropdown menu.

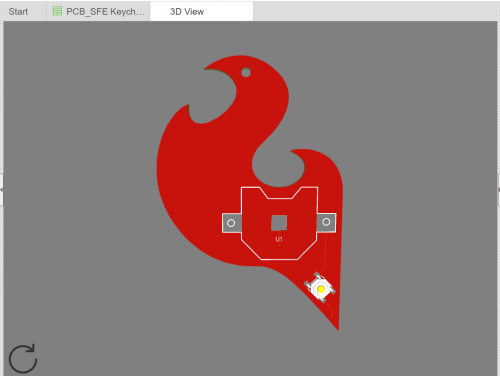

Orienting Components Alongside a Curve

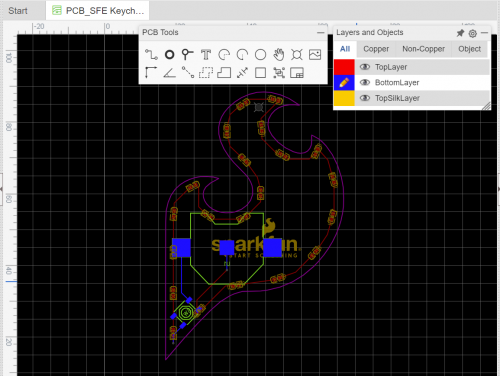

Now that the define is in, we are able to place and join our parts how we’d like! Since my board has these enjoyable curves, I wished to duplicate that form with my LEDs:

The best method to do that is to pick the half and drag the inexperienced dot round till it’s laying the way you need it. You too can choose the half and sort diploma values incrementally within the field labeled ‘Rotation’ on the suitable aspect of the designer.

One factor to pay attention to when orienting elements exterior of 90 diploma increments is how you propose to position them when constructing the board. The best choice is to organize them absolutely constructed from JLCPCB since they’ve acquired all the flowery toys for manufacturing boards. Hand-placing, whereas time consuming, is an efficient method to have the ability to management the orientation your self, however can get a bit of complicated and is simple to bump elements misplaced.

The final choice is to make use of a choose and place in case you have one at your disposal. I’ve labored with the CHMT36VA from Attraction Excessive with curved half placements up to now, and it did nice with them; I used to be constructing lots of boards and did discover a little bit of drift over time, but it surely was a fast recalibrating and we have been again on monitor! In case you’re concerned with studying extra about that machine, test it out right here:

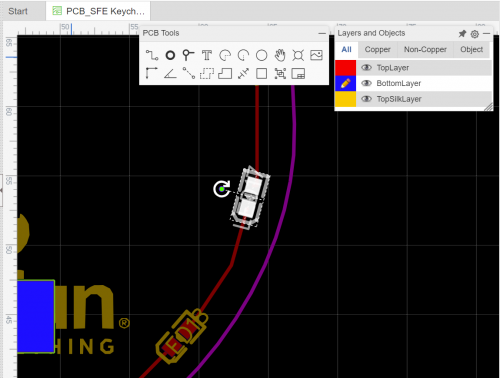

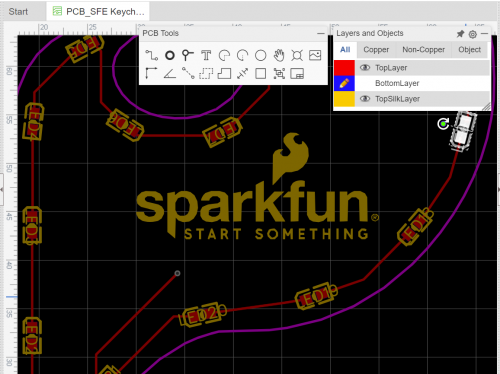

Making a Customized Silk

Subsequent we’re gonna have a look at incorporating a {custom} silkscreen in your board; this course of is similar to the board define, the place you’ll navigate to File → Import → Picture… and choose your file (you may also simply choose the picture icon from the PCB instruments bar and that may open up the identical immediate window). Take note, when deciding on what you need to add, that the silkscreen is a single colour; taking part in with constructive and damaging house permits for lots of dynamic imagery, however can’t fairly do all of it.

One final word with this: the pictures normally place on the TopLayer by default, so you’ll want to choose it and alter the dropdown on the suitable hand aspect to ‘TopSilkLayer’, in any other case it’ll construct as a copper space and be lined by the solder masks. Which, you’d nonetheless be capable of see on the ultimate board, however will intrude along with your traces in the event that they occur to cross paths.

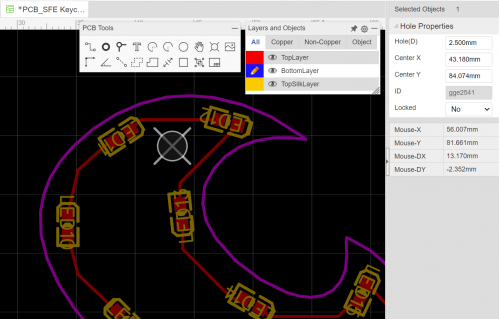

Including a Mounting Gap

Final up, we’re going to take a look at including a mounting gap to the board: these are nice for standoffs, screws, keyrings, just about something that attaches your board to one thing else. It is a actually easy step, with just a few issues to notice; choose the circle with the X behind it from the PCB Instruments bar and place it wherever you’d like. By default, the diameter is 2.032mm and, relying on what you’re trying to thread by way of it, you’ll be able to change this (with the half chosen) on the suitable hand aspect. For keyrings, I discover that bumping it as much as 2.500mm is kind of that Goldilocks zone. In case you’re placing a screw or standoff by way of it, seize some calipers and measure your {hardware} to get a superb match.

Now, you’ll need to contemplate what materials goes by way of the board as effectively; though I didn’t with this design, if I had constructed out a copper space as a VCC or GND aircraft, working a chunk of steel by way of a gap within the board might find yourself shorting it out. In case you’re utilizing copper areas it’s at all times a good suggestion to isolate round holes within the board simply in case. I had a keychain PCB I made some time again that ended up shorting from the wear and tear of it transferring across the steel keyring over time; it was nonetheless enjoyable to have a look at but it surely didn’t gentle up anymore, which is simply merely not as cool.

That’s all, of us!

Thanks all for becoming a member of me for this mini-series, and I hope you’re inspired to take a look at the large world of PCB design. In case you do find yourself dabbling in it, or going all out, please you’ll want to share your initiatives with us!

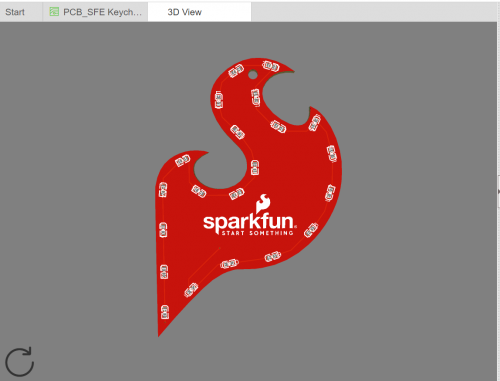

For these , right here’s the ultimate have a look at the 3D view of the board we have been working with:

Designing your personal PCB? Inform us the way it went within the feedback under, or present us on Twitter, Instagram, Fb or LinkedIn.

[ad_2]