[ad_1]

Correct temperature measurements in the course of the laser powder mattress fusion course of in additive manufacturing are essential for producing high-quality elements. Typical thermal infrared cameras have been used to measure soften pool temperatures, however they usually lack the mandatory body fee and determination, resulting in approximations with potential temperature errors. To handle these limitations, researchers from Carnegie Mellon College developed a groundbreaking single-camera technique that gives useful insights into the physics occurring within the soften pool.

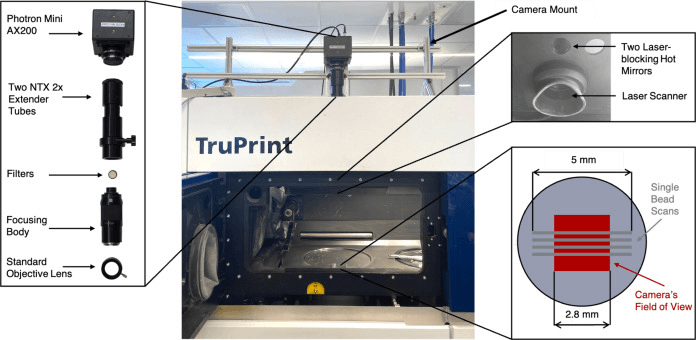

The workforce employed a industrial shade digicam with a built-in Bayer filter to sense seen colours. Every pixel captured gentle from a selected shade, permitting the researchers to amass distinctive measurements for temperature calculations. Through the use of a way known as demosaicing, they reconstructed a full-color picture and measured shade ratios to precisely decide the temperature. This ratiometric method overcomes challenges related to floor properties and consider elements, that are widespread in standard infrared imaging strategies for additive manufacturing.

The advantages of this technique prolong past correct temperature measurements. The researchers have gained useful insights into beforehand unknown parameters within the computational fluid dynamics mannequin. By understanding peak temperatures and gradients within the soften pool, they might examine materials vaporization and the microstructure of the ultimate half.

This new method has proven promising ends in capturing soften pool temperature transients with excessive precision. Moreover, it eliminates the necessity for prior information of soften pool emissivity and plume transmissivity, simplifying the measurement course of.

Transferring ahead, the researchers plan to use this technique to different additive manufacturing processes, similar to wire arc additive manufacturing and directed vitality deposition. The potential functions of this single-camera method open up new potentialities for advancing the standard and effectivity of additive manufacturing, guaranteeing higher management over the manufacturing of crucial elements – important for prime finish manufacturing industries similar to aerospace and nuclear.

You’ll be able to learn the complete analysis paper from the workforce, titled “Excessive-resolution soften pool thermal imaging for metals additive manufacturing utilizing the two-color technique with a shade digicam” on the Additive Manufacturing journal, at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing e-newsletter to get all the newest tales delivered proper to your inbox.

[ad_2]