[ad_1]

A DC motor is often operated by direct present. It converts {the electrical} vitality into mechanical vitality. This rotational motion is the supply of required energy to run many purposes in Business. Velocity management is the essential perform for motor operation. With pace management of the motor, we are able to alter the pace of the motor based on the will of the applying. It’s deployed in lots of real-time purposes like controlling robotic automobiles, paper mills, and elevators.

DC Motor

DC motor is a rotational gadget which converts electrical vitality within the type of Direct Present into mechanical vitality within the type of rotational movement of the motor shaft. The pace of the DC motor could be managed by various DC voltage. For making use of altering voltage, the PWM method is beneficial.

Building and Working

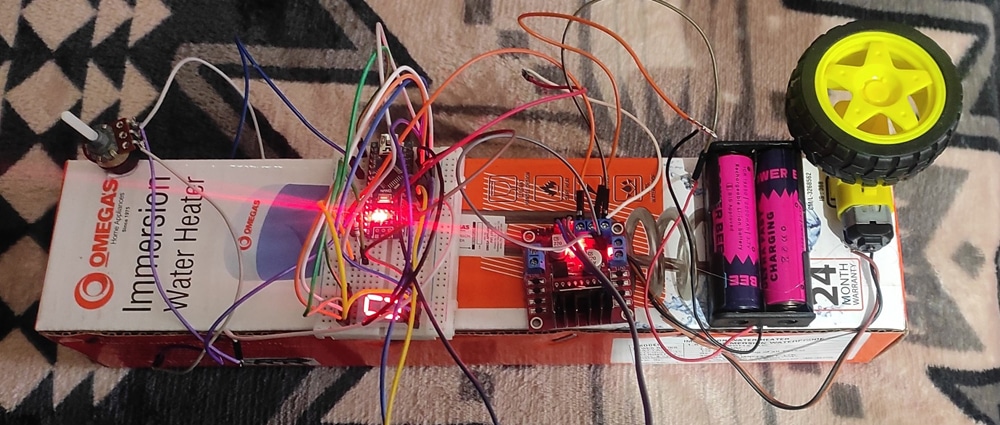

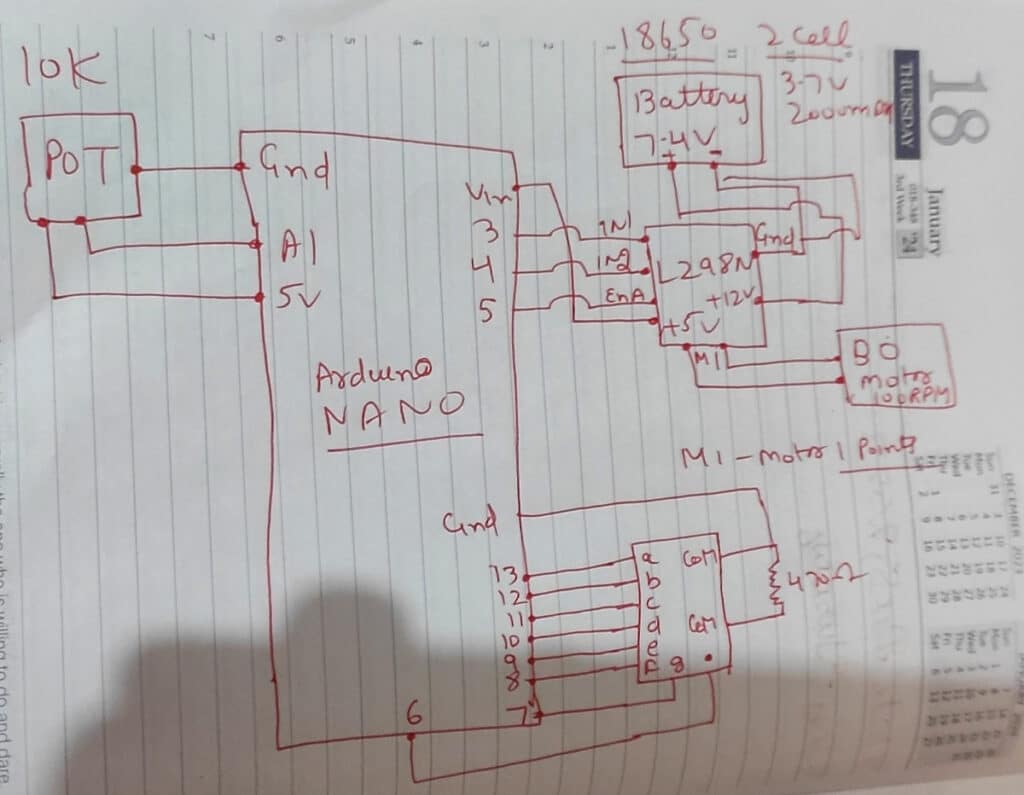

This circuit is constructed on a breadboard. This design relies on Arduino Nano Know-how. It includes Arduino Nano, L298 Motor Driver, Potentiometer 10K,1 Seven phase show, BO Motor 100 RPM, GearBox, Shaft, Battery Holder, Battery 18650 Li-on Cell 3.7V 2000mah (2 cell). Potentiometer has 3 pins – one is linked to GND, one is linked to 5V and the center pin is linked to A1(analog pin). Seven phase pins a to g linked from pin 13 to Pin 7 and the decimal pin linked to six. This can be a widespread cathode 7-segment show with 2 widespread pins linked to GND. Pin 5 of Arduino Nano is linked to Allow Pin A of the L298 Motor Driver. Pin 3, and Pin 4 are linked to IN1 and IN2 of L298 Motor Driver. Connect BO Motors to motor pins of L298 Motor Driver and put wheels inside gearboxes. Motors could be managed via a potentiometer and pace is displayed on a seven-segment show in RPM.

Arduino Nano

The Arduino Nano is a micro-size, full, and breadboard-compatible board based mostly on the ATmega328. The Arduino Nano could be powered through the Mini-B USB connection. The ability supply is routinely chosen to the very best voltage supply. The ATmega328 has 32 KB. Every of the 14 digital pins on the Nano can be utilized as an enter or output, utilizing pinMode(), digitalWrite(), and digitalRead() features. They function at 5 volts. Every pin can present or obtain a most of 40 mA and has an inside pull-up resistor.

L298 Driver:

This L298N Based mostly Motor Driver Module – 2A is a high-power motor driver good for driving DC Motors and Stepper Motors. It makes use of the favored L298 motor driver IC and has the onboard 5V regulator which it may provide to an exterior circuit. It could management as much as 4 DC motors, or 2 DC motors with directional and pace management. This L298N Motor Driver Module – 2A is ideal for robotics and mechatronics initiatives and ideal for controlling motors from microcontrollers, switches, relays, and so forth. Good for driving DC and Stepper motors for micro mouse, line-following robots, robotic arms, and so forth.

Potentiometer 10K

Potentiometers are useful in controlling the varied electrical parameters of a circuit. This can be a one-turn 10k Potentiometer with a rotating knob facility. This potentiometer is used to vary the resistance between 0 to 10k ohms worth by merely rotating the knob. The shaft is 15mm in size with a complete resistance of 10K ohm.

Seven Section Show

In fashionable instances, seven-segment shows are generally utilized in show programs for varied purposes. Seven-segment shows are made up of LEDs. These are used to show numbers just like the standing of petrol in automobiles, time in digital watches, show pace of automobiles, pace of washing machines, AC and varied forms of panels. The seven-segment show accommodates 7 leds to show numbers. You’ll be able to show numbers from 0 to 9 on a single seven-segment.

Widespread Cathode Seven-Section Show

- For the widespread cathode, join widespread pins of seven segments to the GNDpin of Arduino Nano.

- Join +5 volts pin of Arduino Nano to decimal level pin in sequence to a 470 ohm- resistor to restrict the present. It can glow.

- Within the Widespread cathode, a,b,c,d,e,f,g, and h pins of the phase show are linked to Arduino Nano pins which could be managed through programming by assigning values.

Half Record

Arduino Nano, L298 Driver, BO Motor 100 RPM, Widespread cathode Seven Section Show, Potentiometer 10K,Tyre, Bread Board, Jumper Wires, USB Cable, Cardboard Field, Battery Holder, Battery Module 18650 3.7V 2000mah (2 cell)

Software program

Programming of the venture is completed on an Arduino 1.8.19 software. The Potentiometer 10k module is linked to an Arduino Nano analog pin A1, 1 pin linked to 5V of Arduino Nano, 1 pin is linked to GND of Arduino Nano. Pin 5 of Arduino Nano is linked to Allow Pin A of L298 Motor Driver. Pin 3, Pin 4 are linked to IN1 and IN2 of L298 Motor Driver. Connect BO Motor 100 RPM to motor pins of L298 Motor Driver and put wheel inside gearbox. By Software program, Potentiometer sends analog sign to A1 pin and accordingly Arduino Nano sends instructions to L298 Motor Driver which in flip sends instructions to Motor to run based on the worth of potentiometer.

Testing

Make connections as per the circuit diagram. Give voltage from Battery Holder 18650 Li-on Cell 3.7 V 2000 mah(2 cell – 7.4V). Examine the standing of seven-segment show if zero is displaying on it. Transfer the knob of potentiometer 10K and file the pace displayed in RPM from 0 to 9 RPM. Right here 0 means 0 RPM and 9 means 90 RPM and a single dot on seven-segment show means most pace 100 RPM. Observe the pace of BO DC Motor based on the rotation of Knob (0-255). Worth 0 from potentiometer means 0 RPM(revolution per minute-minimum pace), worth 255 refers – 100RPM(most pace). This prototype could be prolonged to 2 or extra motors with extra seven-segment show or LCD show with route management of DC motor for varied robotics and industrial utility.

int seg_Pins[] = {13, 12, 11, 10, 9, 8, 7, 6}; // { a b c d e f g . )

int pot_map;

int pot_input;

////MOTOR1 PINS

int ena = 5;

int in1 = 3;

int in2 = 4;

byte seg_Code[11][8] = {

// a b c d e f g .

{ 1, 1, 1, 1, 1, 1, 0, 1}, // 0

{ 0, 1, 1, 0, 0, 0, 0, 0}, // 1

{ 1, 1, 0, 1, 1, 0, 1, 0}, // 2

{ 1, 1, 1, 1, 0, 0, 1, 0}, // 3

{ 0, 1, 1, 0, 0, 1, 1, 0}, // 4

{ 1, 0, 1, 1, 0, 1, 1, 0}, // 5

{ 1, 0, 1, 1, 1, 1, 1, 0}, // 6

{ 1, 1, 1, 0, 0, 0, 0, 0}, // 7

{ 1, 1, 1, 1, 1, 1, 1, 0}, // 8

{ 1, 1, 1, 1, 0, 1, 1, 0}, // 9

{ 0, 0, 0, 0, 0, 0, 0, 1} // .

};

void setup()

{

pinMode(A1, INPUT);

pinMode(ena, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

for (int i = 0; i < 8; i++)

{

pinMode(seg_Pins[i], OUTPUT);

}

Serial.start(9600);

}

void loop()

{

pot_input = analogRead(A1);

pot_map= map(pot_input, 0, 1023, 0 , 255);

//Serial.println(pot_input);

Serial.println(pot_map);

delay(300);

if ((pot_map > 1) && (pot_map <= 25))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 1; n < 2; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 25) && (pot_map <= 50))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 2; n < 3; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 50) && (pot_map <= 75))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 3; n < 4; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 75) && (pot_map <= 100))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 4; n < 5; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 100) && (pot_map <= 125))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 5; n < 6; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 125) && (pot_map <= 150))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 6; n < 7; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 150) && (pot_map <= 175))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 7; n < 8; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 175) && (pot_map <= 200))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 8; n < 9; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 200) && (pot_map <= 225))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 9; n < 10; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

else if ((pot_map > 225) && (pot_map <= 255))

{

digitalWrite(in1,LOW);

digitalWrite(in2,HIGH);

analogWrite(ena, pot_map);

for (int n = 10; n < 11; n++)

{

display_Digit(n);

delay(2000); ///1 second delay

}

}

else

{

for (int n = 0; n < 1; n++)

{

display_Digit(n);

delay(2000); ///2 second delay

}

}

}

void display_Digit(int digit)

{

for (int i = 0; i < 8; i++)

{

digitalWrite(seg_Pins[i], seg_Code[digit][i]);

}

}Circuit Diagram :

[ad_2]