[ad_1]

In October 2022, Carbon introduced that its developmental bioabsorbable elastomer platform had demonstrated biocompatibility in vivo (in a residing organism), with all samples being categorized as non-toxic and exhibiting tunable occasions for full absorption. The corporate’s bioabsorbable elastomers have the potential for use in biomedical purposes equivalent to comfortable tissue restore, wound dressings and nerve conduits. Bioabsorbable polymers are sometimes utilized in prosthetics as a result of their skill to be engineered to dissolve on the similar fee as new bone progress.

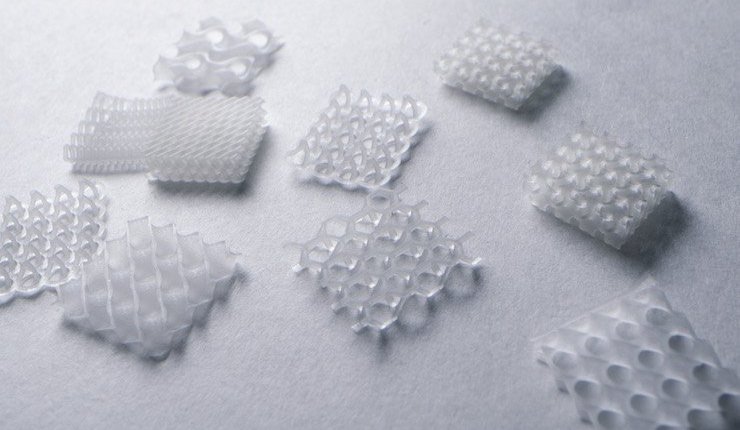

Carbon says, regardless of there being many examples of bioabsorbable supplies that exist within the medical machine business at present, there are few examples of 3D printed elastomeric bioabsorbables. In response to Carbon, its platform of bioabsorbable resin is able to 3D printing customised, advanced, and high-resolution elastomeric lattice buildings. The resins provide tunable degradation, compatibility with gamma sterilisation, and biocompatibility by way of 180 days of in vivo degradation, making them appropriate for comfortable tissue reconstruction and help purposes.

Senior Resin Improvement Supervisor at Carbon Gina Policastro advised TCT: “Functionalising these supplies will not be very simple, however we’re studying increasingly about what persons are doing and within the labs in universities about how we will. The primary hurdle is ensuring you may have sufficient functionalisation websites to get the properties that you really want on the finish of 3D printing; stability is all the time a hurdle. This stuff are supposed to degrade within the presence of water, so water and warmth can break these supplies aside. You might want to be certain that you’re working at temperatures which might be okay to work at, or the size of time is okay to work at. If printing time is just too lengthy, it might have opposed results relying on how briskly or how gradual your polymers are supposed to degrade. You might have an entire toolbox to work with if you’re growing bioabsorbables, and all of the completely different monomers that you just begin with are supposed to degrade at completely different charges, in order that’s a hurdle in itself when growing a bioabsorbable for a specific software.”

Talking about how buildings printed with the supplies are used for wound therapeutic, Policastro advised TCT: “Wound therapeutic cells will begin to infiltrate in, then the cells begin to break the fabric down, and can break it down enzymatically, which is simply pure to your physique. Then it would additionally break down within the presence of water, which you clearly have a ton of in your physique. Because it breaks down, these cells are proliferating and increasing in quantity and actually beginning to regrow that tissue layer, whether or not or not it’s internally or your pores and skin. Primarily simply giving the cells a construction to develop on.”

Standing in the way in which of these kinds of bioabsorbable supplies getting used broadly in healthcare is FDA approval. Solely polymers for particular purposes are being authorised, and since Carbon’s exploration on this space is a brand new kind of chemistry, and additive manufacturing will not be broadly used but in drugs, the approval course of is an enormous hurdle.

Isabelle Palumbo, Enterprise Improvement Director, MedTech at Carbon spoke to TCT in regards to the subsequent step in getting the supplies utilized in healthcare: “We’ve taken the fabric so far as we will. Now we’re on the lookout for companions who’ve concepts for purposes that will leverage this polymer or this biodegradable materials. We’re taking a look at a variety of purposes as a result of there’s nothing else like this in the marketplace but, so our purpose is to discover a associate to work with and finalise the resin, and to help them as they convey it by way of the FDA and scientific trials, after which to market.”

Talking to TCT about why this growth is a milestone, Gary Miller, Head of European Associate and Market Improvement at Carbon mentioned: “I all the time say Carbon is forward of the sport. We’ve acquired supplies which might be world class, and do some improbable issues, and this one other instance of that. We’re bringing one other materials to market that no one has ever thought of. There’s a variety of nice makes use of, however there’s a variety of catching as much as do with what Gina and the remainder of the crew are doing.”

[ad_2]