[ad_1]

By Regan Mills, VP and GM, SOC product advertising, Teradyne

It’s no secret: the semiconductor business is at a crossroads.

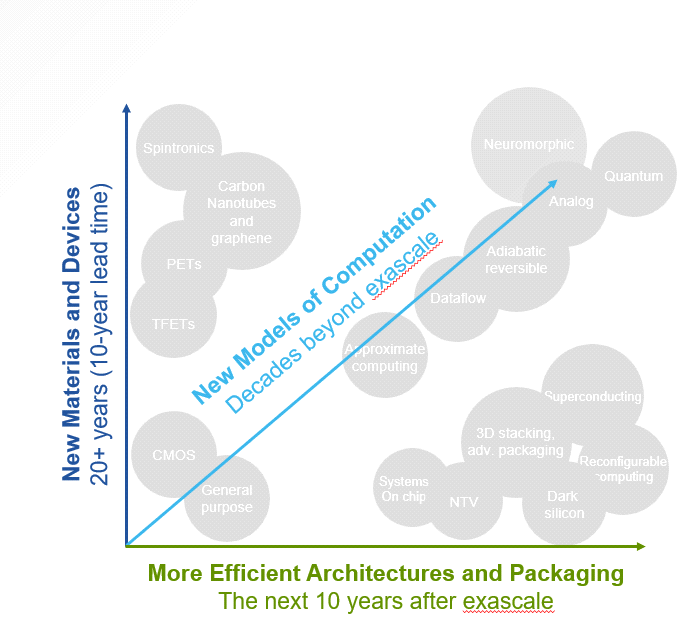

Previously, our business may depend on Moore’s Legislation and Dennard scaling to repeatedly advance every new era of semiconductors. However that’s now not the case as unprecedented challenges, such because the bodily limitations of scaling, have altered this once-linear path. On the identical time, new traits in computing — together with superior packaging methods (e.g., chiplets) and elevated demand for extra highly effective processing — are making gadgets extra complicated. Add a big expertise scarcity to the combination, and it’s clear that we’re on the precipice of the subsequent evolution in semiconductor design and manufacturing.

How will we repair it? By looking for out strategies and methods that additional optimize our current options and processes in ways in which transfer the business ahead.

Collaboration, A A part of the Answer

The assorted phases of the semiconductor lifecycle — design, fabrication and testing —have historically operated in silos, with restricted sharing of data. As an alternative of instantly sharing uncooked information and actual outcomes with each other, the data has been abstracted into specification and information sheets.

For instance, a chip designer could have simulated their authentic design intimately. Nonetheless, as a substitute of instantly sharing the simulation outcomes with different teams, they’ll conventionally distill that data right into a specification sheet — which is the one data that’s handed down the road.

And that’s problematic as a result of many occasions specification sheets don’t seize all of the granular element, so vital data is misplaced. As a result of this lack of transparency obscures necessary particulars, it’s been tough for the semiconductor business to totally optimize designs and processes.

The Function of Information

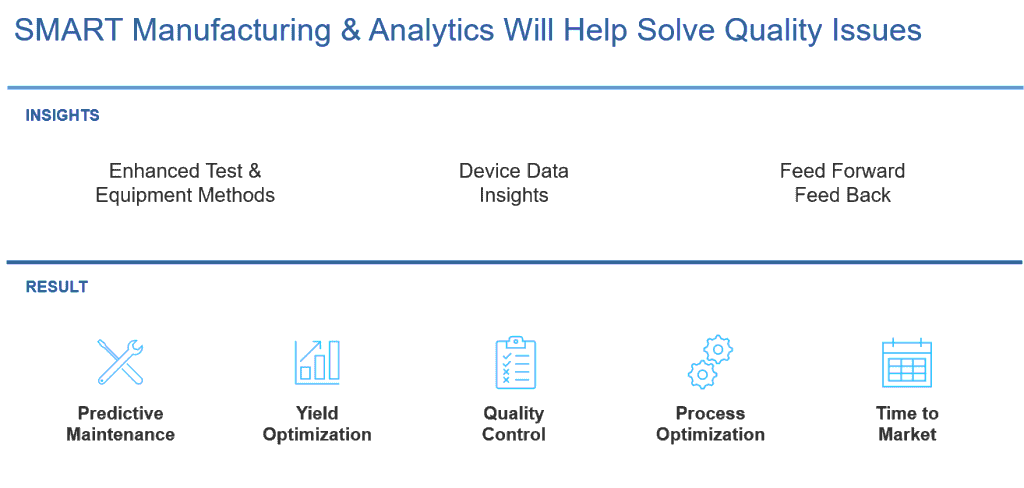

Fortuitously, change is in progress. Superior analytics platforms that depend on subtle ML and AI fashions are enabling each a part of the semiconductor worth chain to benefit from new strategies for analyzing and performing on the huge quantities of information out there through the design and manufacturing course of.

On one hand, sharing can work within the ahead path, with every subsequent stage within the lifecycle receiving information from the earlier stage. If testing teams may entry simulation outcomes, they’d be higher knowledgeable on the tolerances and margins required for his or her check setups. This may produce extra correct and dependable information, leading to higher-quality gadgets and a constructive impression on yield.

Sharing suggestions can also be integral to collaboration. Think about what occurs when a product fails within the area. Right here, sharing lifetime and diagnostic information from the gadget may assist to establish which phases within the lifecycle led to the failure. This suggestions may then be built-in to enhance processes, resulting in better-designed and higher-quality finish gadgets.

By means of analogy, think about a fleet of electrical automobiles (EVs), every outfitted with superior sensors that accumulate information on battery life, motor effectivity and general car efficiency beneath numerous circumstances. If one EV within the fleet experiences a failure, the EV’s communications system may share the info collected as much as the purpose of failure with the automotive producer. This shared data would permit the producer to diagnose the reason for the failure, whether or not it’s a flaw in battery design, a problem with the electrical motor or one other downside in a unique subsystem.

In the identical approach, the semiconductor business can leverage information to establish flaws in processes, the decision of which can result in high quality, yield and effectivity features throughout the board.

Local weather for Collaboration

It’s clear that sharing data has enormous potential for enhancing processes within the semiconductor business. Fortuitously, the local weather for collaboration has by no means been higher. With governments world wide supporting their very own variations of CHIPS Acts, funding and sources within the semiconductor business are at an all-time excessive. This groundswell offers all the semiconductor business the prospect to learn from the momentum.

Merely interfacing, nevertheless, will not be sufficient. We want well-defined requirements, whether or not these are normal file codecs for various facets of the semiconductor lifecycle or a typical technique of sharing information that permit each participant within the worth chain to keep up their differentiation and aggressive edge whereas enabling interoperability.

Peripheral Element Interconnect Specific (PCIe) is a good instance of how requirements can enhance not solely technical efficiency and effectivity but additionally differentiation inside a well-defined system. PCIe, a high-speed, serial bus normal, is the widespread interface between motherboards, and PC {hardware} and peripherals. PCIe gives decrease latency and better information switch charges than earlier requirements, reminiscent of PCI. Trade adoption of this normal has ensured that corporations may create differentiated merchandise primarily based on the supposed software with the boldness that the elements could be interoperable.

The semiconductor business must proceed this evolution, prioritizing the event of latest information requirements that may profit the semiconductor manufacturing ecosystem as a complete.

Change is already underway. SEMI’s Good Information-AI Initiative exemplifies a brand new strategy to business collaboration because it goals to offer a framework for sharing information amongst totally different features inside a fab.

“The worldwide semiconductor business is projected to succeed in $1 trillion by 2030, based on a 2022 report from McKinsey & Firm, however this is not going to occur on ‘auto-pilot.’ To perform this, we might want to proceed the tempo of innovation to make billions of more and more complicated microelectronic gadgets — all of which should be examined for efficiency, reliability and different metrics earlier than they attain their goal software,” stated Dr. Pushkar Apte, strategic technical advisor, SEMI. “If we’re to keep up excessive efficiency and high quality on such a large scale, we have to embrace the strategic integration of information analytics, machine studying and AI in semiconductor manufacturing processes. SEMI’s Good Information-AI Initiative gives a platform to drive value-creation from information and AI which might be particular to the semiconductor ecosystem. The initiative allows pre-competitive collaboration by means of all the ecosystem to speed up innovation whereas preserving the integrity of a person firm’s IP.”

With this basis starting to take form, how will we deal with the resultant inflow of information analytics?

At Teradyne, we facilitate sharing by means of analytics options which might be primarily based on an open structure. This strategy lets our prospects simply combine off-the-shelf information analytics options from third-party corporations with our testers. And since our structure is agnostic, prospects can even use the identical open structure with their home-grown analytics options. The selection is theirs.

Past Moore’s

The bodily facets of Moore’s Legislation are decelerating, however that doesn’t necessitate a slowdown in semiconductor developments. On this period the place collaboration is taking over an more and more necessary position within the semiconductor business, the chance for brand spanking new paradigms is plentiful, but it surely’s as much as us to evolve the best way the business works collectively.

[ad_2]