[ad_1]

Again in 2010, a nuclear plant in Natanz, Iran, fell sufferer to the Stuxnet malware that focused Simatic Step 7, a software program product for configuring and working programmable logic controllers (PLCs). The assault allowed hackers to take advantage of the PLC models throughout the manufacturing unit and injury nearly one thousand uranium enrichment centrifuges, delivering a extreme blow to the nation’s nuclear program.

Within the case of Iran, this was not essentially a foul factor; we do not really need extra nuclear weapons round, will we?

However think about it was your manufacturing unit, your tools value a number of million {dollars} apiece, and your popularity at stake.

It is all the time helpful to place issues into perspective, proper?

What we’re driving at right here: your small business can’t afford to take cybersecurity calmly. Significantly, in case you function in extremely aggressive sectors like manufacturing and provide chain administration. And particularly if your organization has tapped into the Web of Issues software program growth – identical to 72% of your rivals.

From detecting anomalies in tools efficiency earlier than failures happen to monitoring stock ranges in actual time utilizing RFID tags and BLE beacons, there are lots of thrilling IIoT functions and advantages to contemplate. And simply as some ways your IIoT resolution may compromise your complete IT infrastructure, resulting in the next penalties:

- Broken equipment

- Manufacturing downtim

- Accidents on the manufacturing unit flooring

- Knowledge breach

- Reputational injury

- And direct and oblique monetary losses brought on by the entire above

What are the important thing elements placing IIoT safety in danger – and the way may your organization foresee and remedy the Industrial Web of Issues safety challenges earlier than catastrophe strikes?

Let’s remedy the riddle collectively!

Rundown of IIoT safety faults and challenges

For readability’s sake, let’s outline the Industrial Web of Issues and its know-how parts earlier than zooming in on IIoT safety implications.

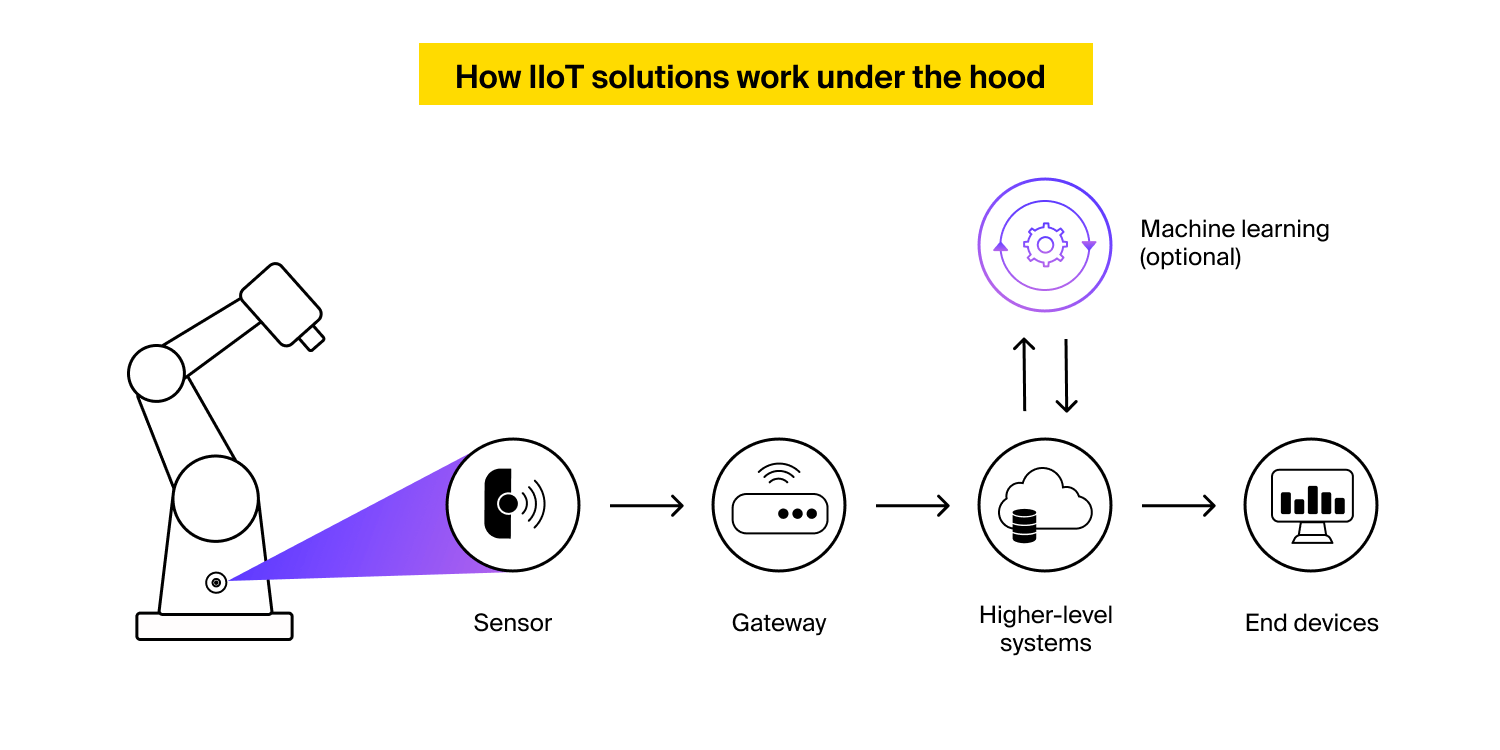

The IIoT time period refers back to the interconnected community of machines, sensors, controllers, and programs that talk and change information with one another and central platforms in industrial settings.

Such cyber-physical programs mix parts of conventional industrial tools with connectivity, information analytics, and information visualization. Corporations flip to IIoT consultants to observe manufacturing and warehouse operations and automate single processes or complete workflows.

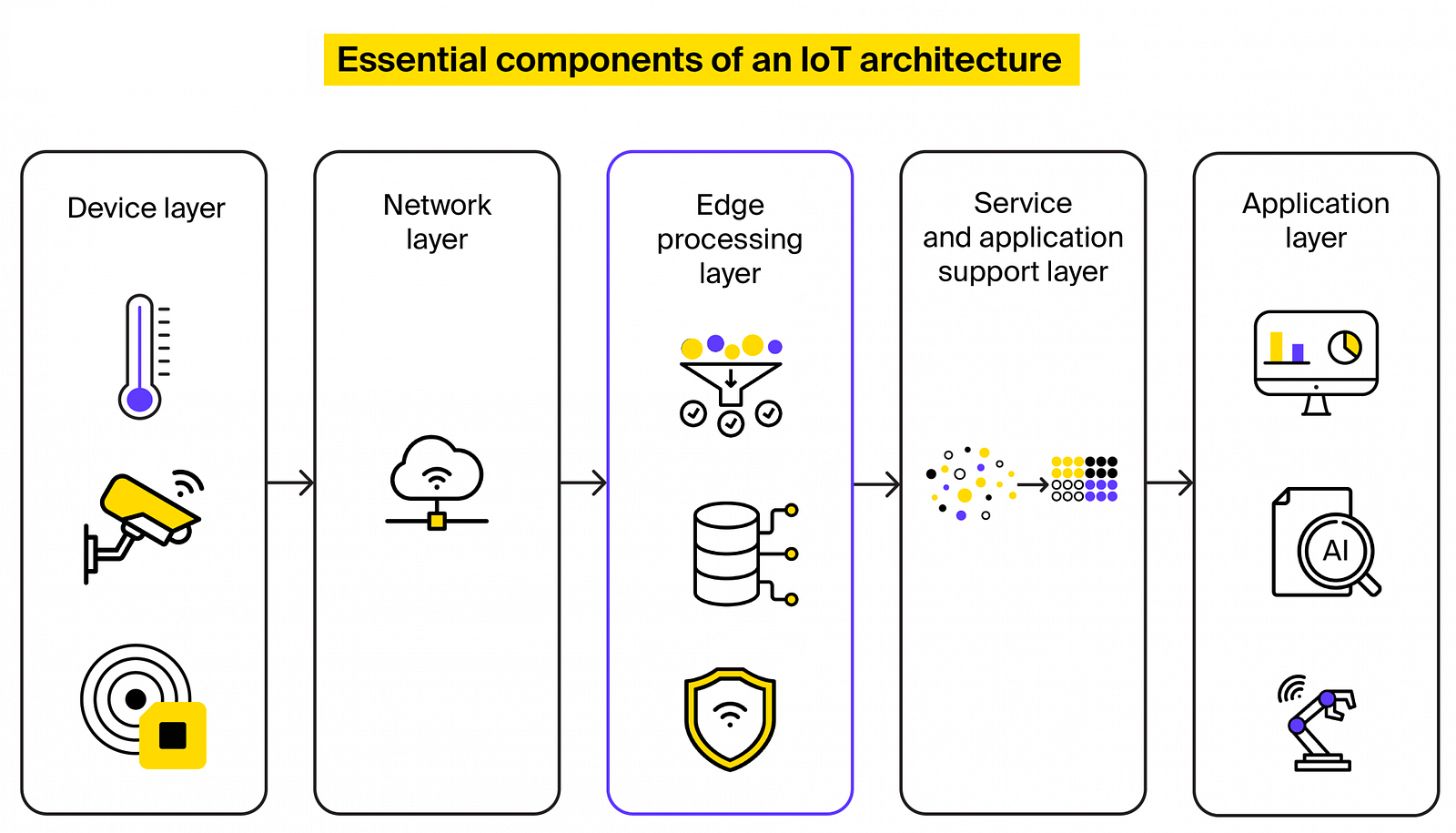

Behind the scenes, the Industrial IoT has the identical structure as each different Web of Issues resolution, though edge IoT deployments the place information is analyzed nearer to sensors prevail in industrial settings.

Corporations tapping into IIoT might procure brand-new tools enhanced with sensors and supporting connectivity by default or improve present equipment utilizing customized and off-the-shelf IIoT retrofit kits.

From the Industrial IoT safety standpoint, why is it necessary to grasp how IIoT programs perform behind the scenes?

IIoT safety points can manifest themselves at each tier of your cyber-physical system – from programmable controllers to legacy apps containing unpatched vulnerabilities. To mitigate IIoT safety dangers, your organization ought to thus shield all endpoints in your wired or wi-fi community, safe information in transit and at relaxation, and patch safety loopholes in functions comprising your IT infrastructure.

With out additional ado, let’s examine what elements undermine safety in IIoT options – and what you are able to do to defend your cyber-physical programs from these threats.

Problem #1: Unsecured communications

Connectivity applied sciences are the spine of all IoT programs, regardless of the complexity and space of utility.

In industrial settings, as extra gadgets and sensors go browsing, extra endpoints, communication channels, and information storage options emerge. And this requires a really various and, ideally, balanced combination of information and networking protocols assembly particular IIoT safety necessities.

At the moment, as much as 98% of all IoT visitors is unencrypted, which means hackers can simply bypass the primary line of protection – e.g., by studying a consumer’s login and password by way of a phishing assault – and lay their arms in your firm’s information.

Poor encryption practices stem from utilizing legacy communication applied sciences, resembling Modbus, Profibus, and DeviceNet. Actually, many of the legacy IIoT communication protocols lack information encryption capabilities altogether, forcing IoT builders to search for workarounds, resembling implementing VPNs and safe tunnels or gateways and addressing encryption points on the Safe Sockets Layer (SSL)/Transport Layer Safety (TLS) degree.

Resolution

To safe information change between the parts of an IIoT resolution and thus stop the Industrial Web of Issues safety accidents, we advocate you implement a fail-proof connectivity tech stack consisting of:

- Dependable information protocols. In Industrial IoT, information protocols decide how data is structured, encoded, and interpreted by gadgets. If your organization opts for a wired IIoT deployment, you may facilitate information change between linked tools and gateways by means of the Ethernet protocols, resembling Profinet, EtherNet/IP, and Modbus TCP/IP. Whereas these protocols don’t inherently help information encryption, your IIoT builders can nonetheless make information unreadable to 3rd events by implementing the TLS/SSL tech stack on the transport layer or introducing middleman gadgets, resembling safe gateways or firewalls, between linked gadgets and the community. Do you have to search for a extra versatile information protocol for IIoT and industrial automation options, we extremely advocate the OPC Unified Structure (OPC UA) protocol, which helps end-to-end encryption, employs X.509 digital certificates for system authentication, and can be utilized in each wired and wi-fi IIoT options. When constructing wi-fi IIoT programs, the ITRex workforce often sticks to Message Queuing Telemetry Transport (MQTT), Constrained Software Protocol (CoAP), Superior Message Queuing Protocol (AMQP), WebSockets, or RESTful APIs with HTTPS. These trendy protocols provide encryption capabilities by means of TLS/SSL or Datagram Transport Layer Safety (DTLS) and assist set up safe communication channels between linked tools, gateways, and cloud servers. For extra details about information protocols and their impression on Industrial IoT safety, e book a free session with our R&D workforce.

- Safe networking protocols. Not like information protocols, which principally cope with data change and interoperability, community protocols outline guidelines, requirements, and procedures for the way gadgets are linked, how information is transmitted, and the way the parts of an IIoT system work together inside a community. From the Industrial IoT safety standpoint, networking protocols may be engaging targets for hackers. Some causes for that embody restricted entry management and authentication mechanisms and an absence of information encryption capabilities. Relying in your community structure – i.e., point-to-point, star, or mesh patterns – and meant use instances, you possibly can make the most of varied networking protocols to deal with IIoT safety challenges. These protocols span Knowledge Distribution Service (DDS), Low Energy Broad Space Community (LoRaWAN), Zigbee, WirelessHART, and Narrowband IoT (NB-IoT). To pick out the suitable connectivity tech stack assembly your entire IIoT safety wants, it is very important contemplate the kind of cyber-physical system you are trying to construct, the required information transmission vary, and energy consumption necessities. This may be accomplished throughout the discovery part of your IoT mission.

Problem #2: Insufficient software program replace practices

Not like computer systems, tablets, and smartphones, IoT gadgets don’t help endpoint safety programs, resembling antivirus applications – just because they usually run extremely personalized or outdated embedded software program or are particularly designed to be small and energy-efficient.

When you can partially remedy Industrial IoT safety challenges by introducing firewalls, intrusion detection and prevention (IDP), and system management mechanisms on the community degree, upgrading the functions constituting your IIoT software program ecosystem to the newest model turns into important for resolving doable IIoT safety points.

Talking of IIoT software program, we have to draw the road between embedded programs, resembling firmware, middleware, and working programs (OSs), and unusual software program – assume net, desktop, and cell functions facilitating system administration.

Because of IIoT system design constraints and numerous endpoints inside a cyber-physical system, patching IIoT software program safety vulnerabilities is a activity few industrial corporations can handle. That is why as much as 65% of producers nonetheless use outdated working programs ridden with zero-day safety vulnerabilities.

Resolution

To mitigate IIoT cybersecurity dangers, an industrial firm should have an environment friendly software program replace administration mechanism in place.

Right here at ITRex, we’re robust advocates of software program and firmware updates over the air (OTA). On this state of affairs, a cloud-based platform powered by AWS IoT System Administration, Azure IoT Hub, or pre-configured SaaS options like Bosch IoT Rollouts robotically delivers software program updates to edge gadgets, controllers, and gateways.

A correctly configured system administration platform can even maintain higher monitor of your system fleet, optimize replace rollouts contemplating device-specific settings and safety necessities, and notify your IT workforce in emergencies.

Problem #3: Poor bodily safety measures

Community IIoT safety apart, a cyber-aware industrial firm must also stop cybercriminals and malicious insiders from stealing {hardware} with the objective of scanning the gadgets’ inside and infesting them with viruses and spying applications.

Inadequate bodily safety measures not solely compromise the integrity and confidentiality of delicate information, but in addition result in service disruptions, operational downtime, and monetary losses. The repercussions of bodily safety vulnerabilities can lengthen past the quick impression, doubtlessly endangering public security and significant infrastructure.

Resolution

To handle the poor bodily safety points in industrial IoT, a multi-faceted method is required. Here is what your organization ought to do as a part of the bodily IIoT safety overhaul:

- Prioritize the implementation of sturdy entry management mechanisms. This contains measures resembling role-based entry management (RBAC) to linked tools, biometric authentication, laptop imaginative and prescient-powered video surveillance, and the implementation of intrusion detection programs

- Conduct common bodily safety audits and threat assessments. The Industrial Web of Issues safety audits assist establish vulnerabilities early on and develop acceptable mitigation methods. This proactive method allows organizations to remain one step forward of potential threats and take preventive measures to safeguard their IIoT programs. In apply, this implies disconnecting gadgets with proof of tampering from the community, hiding producer markings on the gadgets, and, when doable, eradicating pointless IIoT resolution parts to stop reverse engineering occasions

- Implement complete worker coaching applications. Elevating consciousness about bodily safety dangers and finest practices is vital to fortifying the Industrial Web of Issues cybersecurity (extra on that later). Collaboration between IT and bodily safety groups can also be very important. This partnership ensures a holistic method to safety, the place each digital and bodily points are thought of and synchronized to offer sturdy safety towards rising IIoT safety threats.

Problem #4: Restricted visibility into system and community exercise

As much as 90% of organizations report having shadow IoT gadgets on their community, with 44% of the respondents admitting these gadgets have been linked with out the information of their safety or IT groups.

In consequence, corporations are unaware of which gadgets talk with one another, what data they collect and change, and whether or not this data is inaccessible to 3rd events.

And the truth that IIoT safety audits stretch far past figuring out {hardware} options by their IP and working system solely complicates the matter.

Resolution

There are a number of steps you may take to realize system and community visibility in IIoT deployments:

- Analyze all community communications utilizing deep packet inspection (DPI) options

- Accumulate exhaustive system data, together with {hardware} sort, mannequin, serial quantity, and embedded system variations

- Group your gadgets based mostly on their sort, perform, mission criticality, and potential IIoT safety dangers

- Create digital native space networks (VLANs) for each system group to reinforce visitors visibility and management

- Make use of dependable system administration platforms, resembling AWS IoT Core, Azure IoT Hub, and PTC ThingWorks, to enhance system inventories, monitoring, configuration, replace rollouts, and troubleshooting

Problem #5: Inadequate worker coaching and cyber-awareness

As we have talked about earlier, an absence of collaboration and coordination between data know-how (IT) and operational know-how (OT) groups can lead to poor IIoT safety administration practices.

Whereas tools operators and manufacturing unit managers correctly look after linked machines, they know little concerning the embedded and connectivity applied sciences that energy them. IT groups, quite the opposite, are well-versed in conventional data safety however are likely to deal with IIoT options like unusual {hardware}.

This may occasionally result in low patch ranges, restricted visibility into community exercise, and misconfigurations of the Industrial Web of Issues programs. Moreover, cybercriminals might exploit your worker’s restricted information of IIoT safety finest practices by means of phishing assaults and impersonation. Your workforce might also select weak passwords or reuse passwords throughout functions, which can open a backdoor to your IT infrastructure, undermining IIoT software program safety.

Resolution

Here is a high-level plan that would assist your organization elevate cybersecurity consciousness amongst staff:

- Create coaching applications particularly tailor-made to the Industrial IoT setting. These applications ought to cowl subjects resembling cybersecurity fundamentals, IoT system safety, safe configuration practices, password hygiene, recognizing and reporting potential safety incidents, and compliance with inside safety insurance policies and procedures.

- Conduct common coaching periods to make sure staff keep up-to-date with the newest cybersecurity threats and finest practices. This may be accomplished by means of workshops, seminars, webinars, or on-line coaching modules in your studying administration system (LMS). As a part of the coaching actions, for example, you may educate your employees to acknowledge and reply to IIoT safety threats by means of phishing simulations and penetration testing. You must also tailor coaching applications to particular job capabilities, making certain that staff obtain the coaching related to their obligations. For instance, IT employees might require extra technical coaching, whereas operational staff may have coaching on safe system utilization and bodily safety.

- Develop complete insurance policies and procedures that handle the distinctive Industrial Web of Issues safety challenges. Talk these insurance policies successfully to staff and guarantee they perceive their roles and obligations in sustaining safety. Usually evaluation and replace these insurance policies as know-how and threats evolve.

- Promote a tradition of IIoT safety consciousness and accountability all through the group. Encourage staff to report any safety incidents or suspicious actions promptly. Emphasize that cybersecurity is everybody’s duty, from high administration to frontline employees, and reward staff for demonstrating good safety practices.

- Take into account partnering with exterior Industrial IoT consultants or consultants to conduct safety assessments. Exterior consultants can carry useful insights, business finest practices, and the newest menace intelligence to reinforce worker coaching applications. Moreover, they may provide help to carry the so-called “safety by design” practices into the IIoT software program growth course of and elicit purposeful and non-functional necessities for IIoT deployments.

On a closing observe

IIoT adoption charges have soared lately – and so have the high-profile assaults focusing on important IIoT infrastructures within the industrial phase.

In line with a latest survey from Test Level, within the first two months of 2023, 54% of corporations suffered IoT-related assaults, with an estimated 60 assaults per week per group (41% up from final yr). Among the many gadgets most inclined to hacker assaults have been routers, community video recorders, and IP cameras – briefly, {hardware} that includes the spine of each firm’s IT infrastructure.

Even when your IT workforce follows IIoT safety finest practices all through the event and implementation course of, there isn’t any assure hackers will not train management over your tools and information by exploiting vulnerabilities in apps and gadgets exterior the IIoT ecosystem. That is why your organization wants an all-embracing safety technique – and this is what ITRex can do for you!

Whether or not you are contemplating launching an IIoT pilot or need assistance scaling an Industrial IoT proof of idea (PoC) throughout different use instances, drop us a line! We’re well-versed in enterprise evaluation, embedded system engineering, cloud computing and DevOps, and end-user utility growth.

The submit IIoT Safety Challenges & Tricks to Navigate Them appeared first on Datafloq.

[ad_2]