[ad_1]

Auto accidents are accountable for 1.3 million deaths yearly, based on the World Well being Group. That’s like dropping the town of Prague annually. A change to self-driving automobiles and vans with varied sorts of digital sensors and complex computer systems on the helm may save numerous lives. However getting this promising know-how into folks’s arms has been tough, regardless of large analysis investments and appreciable technical progress.

So when will self-driving automobiles actually come to a driveway close to you? The reply relies upon partially on whether or not such automobiles require a kind of sensor referred to as lidar, quick for “gentle detection and ranging.” Most teams growing autonomous autos see lidar as a crucial a part of the sensor suite required for protected operation, as a result of it permits an in depth 3D map of the car’s atmosphere to be constructed with far more constancy than could be achieved with cameras.

Elon Musk, although, has been pushing Tesla to undertake a controversial cameras-only method to autonomous driving. “People drive with eyes & organic neural nets, so is sensible that cameras & silicon neural nets are solely strategy to obtain generalized resolution to self-driving,”

Musk tweeted in 2021. The mechanical complexity and excessive price of most lidar sensors—which not way back would have added tens of hundreds of {dollars} to the worth of every car—little question helped formed Musk’s views. As early as 2016, he declared that “all Tesla autos exiting the manufacturing facility have {hardware} needed for Degree 5 autonomy”—that means that automobiles with cameras and computer systems alone have what’s wanted for totally autonomous driving.

The newest prototype lidar system from Analog Photonics exhibits off its capabilities at a busy intersection in Boston. Analog Photonics

Seven years and plenty of crashes later, Tesla has not progressed previous Degree 2 Autonomy, and

traffic-safety specialists are questioning Musk’s rejection of lidar. Requiring expensive sensors, although, would gradual the widespread rollout of each superior driver-assistance programs and totally autonomous driving. However decreasing the price of these sensors to a stage that might fulfill automakers has remained an elusive aim for lidar producers, which should additionally take into account learn how to add their units to automobiles with out detracting from car aesthetics.

We and others at our firm,

Analog Photonics, which spun out of MIT in 2016, hope to interrupt this deadlock. We’re growing a tiny, chip-scale phased-array lidar that guarantees to slash prices and simplify integration. Right here we’d like to elucidate a number of the technical challenges we’ve encountered and the way very shut we’re to commercialization.

From Radar to Lidar

Right now, greater than half of recent automobiles are outfitted with a number of radar sensors. These sensors are strong state, price producers lower than US $100 every, and are sufficiently small to be inconspicuously positioned across the car. They’re used for a wide range of issues, together with automated emergency braking and adaptive cruise management, in addition to lane protecting and different superior driver-assistance capabilities.

However this wasn’t all the time the case.

Early automotive radars have been giant, mechanically steered, emitted quick pulses of radio waves, and had restricted efficiency. However the transfer to digital scanning and continuous-wave emissions in automotive radars introduced efficiency developments and price reductions, which in flip ushered of their widespread use.

Lidar is now present process this identical evolution. The know-how started making headlines round 2016 as a slew of corporations, spurred on by the success of lidar sensors on autos entered within the

DARPA Grand Problem a decade earlier, started growing customized programs for autonomous autos. These programs tended to be pieced collectively from off-the-shelf elements.

This animation exhibits how delaying the sign despatched from a collection of emitters can be utilized to steer the transmission in several instructions. Such phased arrays of emitters are sometimes used for radar, however they may also be used to steer the sunshine beam in a lidar system. Sandeep Sharma

This animation exhibits how delaying the sign despatched from a collection of emitters can be utilized to steer the transmission in several instructions. Such phased arrays of emitters are sometimes used for radar, however they may also be used to steer the sunshine beam in a lidar system. Sandeep Sharma

These first-generation lidars went solely to this point. Spinning or scanning mirrors contributed to their excessive prices and made their integration into autos tough. In addition they suffered from reliability points, and their pulsed operation led to issues within the presence of direct daylight and resulted in an inherent susceptibility to interference from neighboring lidars. Consequently, the out there lidar sensors haven’t met the stringent efficiency, reliability, and price targets of the automotive business.

Carmakers are on the lookout for high-performance, long-range lidar sensors that may price them lower than $500 every. Whereas lidar producers have made progress, the business isn’t there simply but.

Our firm selected to assault these issues head-on by designing lidar sensors which might be constructed totally on a chip—a photonic built-in circuit manufactured from extraordinary silicon. It has no shifting components and generates, emits, and receives gentle with no exterior {hardware}. And its tiny measurement makes it simple to include into the our bodies of even the sleekest automobiles on the highway.

Lidar is quite a bit like radar, nevertheless it operates within the infrared portion of the spectrum, with wavelengths sometimes between 905 and 1,550 nanometers (in contrast with a couple of millimeters for automotive radar). This distinction in wavelength offers lidar significantly better spatial decision, as a result of the waves despatched out from the sensor could be extra tightly targeted.

Recognizing that the physics of a phased array apply to all frequencies of the electromagnetic spectrum, we determined to make use of this method in our solid-state lidar.

Most early automotive lidars, like most early radars, used what is named time-of-flight (ToF) detection. A brief pulse of electromagnetic vitality is distributed out, hits an object, after which displays again to the sensor, which measures the time it takes for the heart beat to finish this spherical journey. The unit then calculates the vary to the thing utilizing the recognized pace of sunshine in air. These programs all undergo from some inherent limitations. Particularly, lidars constructed on this precept are liable to interference from daylight and from gentle pulses coming from different lidars.

Most fashionable radars programs work otherwise. As an alternative of sending out pulses, they emit radio waves repeatedly. The frequency of those emissions will not be fastened. As an alternative, they’re swept forwards and backwards throughout a spread of frequencies.

To know the rationale for doing that, it’s necessary to know what occurs when alerts of two completely different frequencies are mixed in a method that isn’t purely additive. Doing so will generate two new frequencies: the sum and distinction of the 2 frequencies you initially combined. This course of, referred to as

heterodyning, was first demonstrated in 1901 and has since been used broadly in radio gear.

Frequency-modulated continuous-wave (FMCW) radars make the most of the truth that alerts of two completely different frequencies, when combined on this vogue, give rise to a sign whose frequency is the distinction of the primary two. In these radars, the blending is completed between the outgoing sign (or, in fact, an attenuated model of it, usually referred to as the native oscillator) and the mirrored sign, which differ in frequency as a result of the outgoing sign is, as we talked about, being swept throughout a spread of frequencies. So by the point the mirrored sign makes it again to the sensor, the outgoing sign may have a special frequency from what it had when the now-reflected waves first left the radar antenna.

If the mirrored sign took a very long time to make the spherical journey, the distinction in frequencies shall be giant. If the mirrored sign took solely a short while to bounce again, the distinction in frequencies shall be small. So the distinction in frequencies between outgoing and mirrored alerts supplies a measure of how distant the goal is.

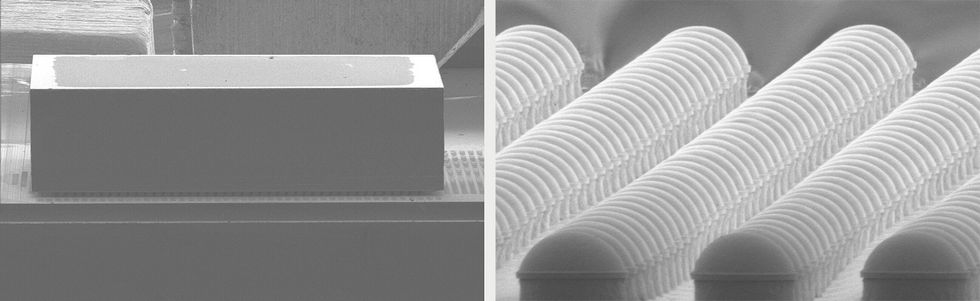

The authors’ lidar consists of two components: a silicon photonic chip and a semiconductor chip [electron micrograph at left]. The latter comprises

The authors’ lidar consists of two components: a silicon photonic chip and a semiconductor chip [electron micrograph at left]. The latter comprises

the electronics that management the various photonic parts. A better-magnification

micrograph particulars the tiny copper bumps which might be used to make {the electrical}

connections between these two chips [right].

ANALOG PHOTONICS

Whereas they’re extra complicated than ToF-based programs, FMCW programs are extra delicate, basically proof against interference, and can be utilized to measure the rate of a goal along with its distance.

Automotive lidar is now adopting an identical method. FMCW lidar entails barely altering the frequency, and thus the wavelength, of the transmitted gentle after which combining the backscattered gentle with a neighborhood oscillator on the frequency of the transmitted gentle. By measuring the frequency distinction between the obtained gentle and the native oscillator, the system can decide the vary to focus on. What’s extra, any Doppler shifts from a shifting goal

may also be extracted, revealing the goal’s velocity towards or away from the sensor.

This functionality is beneficial for shortly figuring out shifting targets and discriminating amongst carefully spaced objects which might be shifting at completely different speeds. The speed measurement may also be used to foretell different car actions and may even sense a pedestrian’s gestures. This extra dimension to the info, not out there from ToF programs, is why FMCW programs are typically referred to as

4D lidar.

As you may think, FMCW lidar programs use a really completely different laser supply than ToF programs do. FMCW lidars emit gentle repeatedly, and that gentle has comparatively low peak energy. The laser energy ranges are much like these utilized in many communications functions, that means that the sunshine could be generated and processed by photonic built-in circuits. This tiny laser system is without doubt one of the key components that has enabled chip-based lidars.

Steering Gentle with Phased Arrays

The photonic built-in circuits we designed could be fabricated on commonplace 300-millimeter-diameter silicon wafers utilizing photolithography, simply as is completed for many built-in circuits. So we are able to make the most of the maturity of the CMOS semiconductor-manufacturing business to mix the entire varied on-chip optical elements wanted for a full lidar system: lasers, optical amplifiers, waveguides, splitters, modulators, photodetectors, and, in our case, optical phased arrays.

The economies of semiconductor manufacturing slash the price of every of those elements. Having all of them built-in on a single chip helps, too. You see, all lidar programs each transmit gentle and obtain gentle, and the transmitting and receiving optics have to be effectively aligned. In programs constructed with discrete optical elements, the necessity for exact alignment provides complexity, manufacturing time, and price. When issues slip out of alignment, the lidar can fail. With built-in photonics, the exact alignment is inherent, as a result of the waveguides carrying the sunshine are lithographically outlined.

These renderings present what the lidar fashions now in improvement are anticipated to seem like. The one on the left is designed for lengthy vary with a slender area of view, whereas the one on the fitting will function at quick vary with a large area of view.ANALOG PHOTONICS

These renderings present what the lidar fashions now in improvement are anticipated to seem like. The one on the left is designed for lengthy vary with a slender area of view, whereas the one on the fitting will function at quick vary with a large area of view.ANALOG PHOTONICS

Whereas a handful of corporations are working to develop photonic IC–primarily based lidars, solely Analog Photonics has found out learn how to get rid of the necessity to mechanically scan the scene with its single-chip lidar. As an alternative of mechanical scanning, we use what are referred to as optical phased arrays, which permit the beam to be steered electronically.

Scanning is an important facet of lidar and one of many key challenges of the know-how. The system builds an image of its environment by scanning the scene with a number of laser beams. To detect and determine targets shortly, the lidar should quickly scan its complete area of view, doing so with sufficiently excessive decision to tell apart completely different objects.

Initially, lidar sensors scanned by both spinning the sensor itself or introducing rotating mirrors into the beam path. The ensuing {hardware} was cumbersome, costly, and sometimes unreliable.

Though some radars additionally level their antennas mechanically—as you don’t have any doubt seen at airports and marinas—some steer the radar beam electronically utilizing

phased antenna arrays. This method adjusts the section of the alerts leaving every of a number of antennas in such a method that radio waves intervene with each other constructively in a single path and destructively in different instructions. By adjusting sign phases at every antenna, the radar can range the path through which these alerts mix constructively to kind a beam.

Electronically phased arrays are the beam-steering know-how of alternative for automotive radars. Recognizing that the physics of a phased array applies to all frequencies of the electromagnetic spectrum, together with optical frequencies, we determined to make use of this method in our solid-state lidar. Aided by the Protection Superior Analysis Initiatives Company by means of its

Modular Optical Aperture Constructing Blocks program, and with assist from a number of automotive companions (whose names we are able to’t but reveal), Analog Photonics has developed on-chip optical phased arrays.

For these arrays, the highest floor of the chip is used as each a transmitting and receiving aperture—that’s the place the vitality leaves and returns to the chip. The on-chip optical section shifters and emitters are individually managed with customized electronics to steer exceedingly tight optical beams, ones which might be simply a number of millimeters vast.

Reaching a spread of steering that’s giant sufficient to be helpful requires hundreds of carefully spaced section shifters. For instance, for a lidar that operates at a wavelength of 1,550 nm, the section shifters have to be positioned simply 1.5 micrometers aside to allow a 60-degree steering vary.

You would possibly surprise how all this optical section shifting is completed. It requires altering the optical properties of the clear materials contained in the chip’s many micrometer-scale optical waveguides, which channel the sunshine from the laser the place it’s generated to the aperture the place it’s emitted. If you happen to can change the pace of sunshine in that materials, you’ll alter the section of the sunshine wave exiting the waveguide.

The fabric right here is simply silicon, which is clear to gentle at infrared wavelengths. One strategy to alter the pace of sunshine in silicon is to move sound waves by means of it, a method

being pursued to be used in lidar by researchers on the College of Washington. One other method is to alter the temperature: The warmer the silicon, the extra the sunshine passing by means of it’s slowed. That is the precept behind what are referred to as thermo-optic section shifters.

With hundreds of section shifters on a chip, it’s crucial that every one devour little or no energy, mere microwatts. And that’s arduous to do when you need to warmth issues up. We sidestepped the necessity for heating through the use of electro-optic reasonably than thermo-optic section shifters. This method additionally enabled us to steer the beam sooner, permitting it to step throughout the sector of view at charges exceeding a million scan traces per second.

There remained, although, the problem of learn how to join the various carefully spaced optical waveguides with the electronics required to regulate the pace of sunshine inside them. We solved this utilizing

flip-chip know-how: One CMOS chip has hundreds of solder-coated copper bumps positioned about 75 micrometers aside, or about half the width of a human hair. This scheme permits our silicon photonics chip to be completely mated with a semiconductor digital chip containing the wanted digital logic and an identical set of copper bumps. Easy instructions to the digital chip then drive hundreds of photonic elements within the applicable vogue to brush the beam.

A Lidar-Wealthy Future

This working prototype for the authors’ long-range lidar is way bigger than the completed product shall be. Analog Photonics

This working prototype for the authors’ long-range lidar is way bigger than the completed product shall be. Analog Photonics

Analog Photonics has now constructed and delivered prototypes of the world’s first all-solid-state beam-sweeping lidar to its business companions, that are corporations that offer automotive gear on to carmakers. We’ve solved many of the elementary and engineering challenges and are actually targeted on rising the lidar’s efficiency to satisfy manufacturing specs. We count on to be turning our creations into precise merchandise and producing giant numbers of samples for the automotive business in 2025.

We’re presently engaged on two completely different variations of our lidar: a long-range model meant to be mounted on the entrance of the automobile to be used at freeway speeds and a short-range model with a wider area of view to offer full protection throughout the car. The 2 sensors have completely different optical phased arrays of their photonic ICs, whereas sharing the identical back-end sign processing.

We count on that comparatively low-cost lidar sensors from a few of our rivals, akin to

Cepton and Luminar, will start displaying up in some top-of-the line automobiles as early as subsequent 12 months. And pushed by the provision of low-cost solid-state sensors like those we’re engaged on, lidar shall be widespread in new automobiles by the top of the last decade.

However the way forward for lidar received’t finish there. Market forecasters count on lidar for use for a lot of different functions, together with industrial automation and robots, mobile-device functions, precision agriculture, surveying, and gaming. And the form of work we and others are doing with silicon-photonic ICs ought to assist make that vivid, lidar-filled future arrive all the earlier.

From Your Web site Articles

Associated Articles Across the Internet

[ad_2]