[ad_1]

Nominations at the moment are open for the 3D Printing Business Awards 2023. Who’re the leaders in 3D printing? Discover out on November thirtieth when the winners throughout twenty classes shall be introduced throughout a London-based dwell awards ceremony.

Steel 3D printing firm Meltio has launched its new Meltio Area software program, which it hopes will enhance the adoption of the corporate’s wire-laser steel robotic 3D printing options.

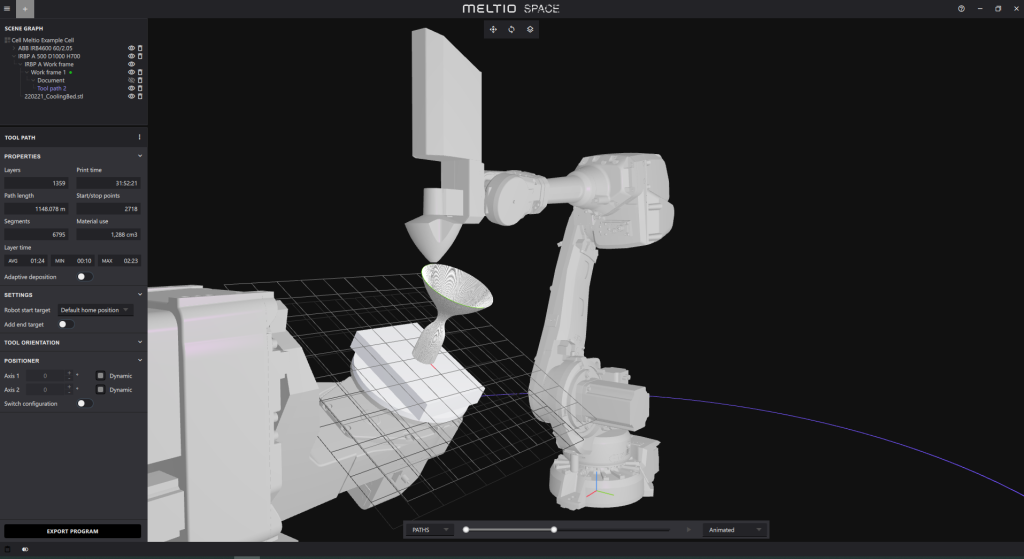

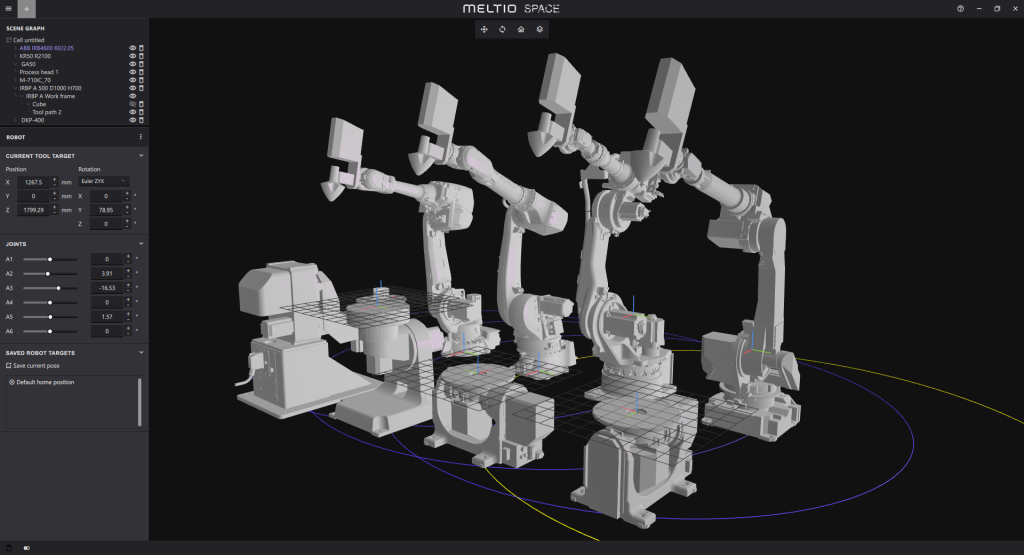

A toolpath generator software program for Meltio Engine Robotic Integration, Meltio Area incorporates a user-friendly interface for planar, non-planar, and variable extrusion toolpaths. 2-axis workpiece positioner interpolation, kinematics simulation, collisions test, and cell configuration are additionally included with the platform.

Preset and really useful supplies profiles are integrated, in addition to a inbuilt robotic library and post-processors for robotic arms from ABB, Kuka, Fanuc, and Yaskawa. The corporate claims that its new software program removes complexity from the 3D printing workflow, making it accessible to customers of all ranges.

The software program is bought as an annual subscription, the value of which is claimed to be the “best in the marketplace for additive manufacturing tailored to a robotic arm.” Furthermore, Meltio Area is free for the primary 12 months when bought alongside the Meltio Engine.

“Meltio Area makes it doable to design very dependable elements as shortly as doable and with a wider vary of prospects for our industrial clients. And that is due to a really user-friendly interface of the Meltio Engine Robotic Integration,” commented Meltio Engine Product Supervisor Alejandro Nieto.

“The primary aim of our know-how is to provide essentially the most environment friendly software that permits the trade the a lot of the functions they should manufacture steel elements with our wire-laser know-how. Meltio Area is a dwelling platform that may present suggestions to maintain enhancing and provide aggressive software program to totally different industrial clients of Meltio”.

Meltio’s new toolpath generator software program

Final 12 months, Meltio signed an settlement with 12 main software program firms to kind the Meltio Engine Software program Companions ecosystem, with these firms having fun with open compatibility with Meltio know-how.

Now, due to Meltio Area, this wire-laser know-how has been made obtainable to a wider vary of commercial clients who don’t possess experience in robotics and additive manufacturing. Certainly, the toolpath generator software program has been particularly developed to speed up the adoption of Meltio know-how throughout the industrial additive manufacturing house.

In response to Meltio, this new software program streamlines your complete additive manufacturing course of, providing a unified platform that enhances workflow effectivity and productiveness. Person expertise is claimed to be key to the platform, which supplies “seamless integration” between Meltio Area and the Meltio Engine.

Moreover, the Meltio Area robotic slicer features a digital mannequin of the actual robotic’s actions. This enables customers to precisely simulate the kinematics of the robotic, guaranteeing exact and correct 3D printing while decreasing programming time. The slicer additionally performs collision checks all through the 3D printing course of, decreasing the danger of errors or harm.

By offering numerous toolpath methods, Meltio Area permits exact actions for intricate 3D printed designs. Providing enhanced 3D print profiles for a variety of supplies and functions, the software program optimizes Meltio Engine functionalities. Meltio Area can even be frequently up to date and developed, with Meltio providing a variety of assist, coaching packages, and useful resource platforms as a part of the package deal.

In the end, Meltio claims that its Area software program will assist to advance additive manufacturing past the standard 3-axis system, accelerating the combination of the corporate’s 6-axis robotic manipulator and 2-axis workpiece positioners. It’s hoped that the software program’s complete coordination, multi-axis toolpath era, and elevated design freedom will permit customers to 3D print extra intricate and extremely detailed elements.

Current developments in 3D printing software program

Plenty of firms have sought to optimize the additive manufacturing course of by way of new software program choices. As an example, engineering software program developer nTop (beforehand nTopology) lately launched a big replace to its flagship product: nTop 4.

By way of this replace, nTop’s 3D printing software program gives new digital instruments to design and 3D print complicated elements, permitting engineers to beat additive manufacturing bottlenecks. In response to nTop, this new platform permits enhanced design flexibility, decreased time to market, value reductions, and improved end-part high quality.

“nTop 4 marks the following stage of our journey enabling engineers to ship extremely engineered AM elements for merchandise to succeed in new ranges of efficiency,” commented Bradley Rothenberg, nTop Co-founder, and CEO.

Elsewhere, 3D printer producer EOS North America and its Additive Minds utilized engineering group lately launched Can I 3D Print This, a web based software that seeks to make industrial 3D printing extra accessible to additive manufacturing newcomers. By way of this free platform, customers can enter details about their desired half, with the software program then producing a report analyzing the half’s 3D printability.

“Our new Can I 3D Print This software helps with preliminary decision-making by empowering potential customers to discover and collect details about the promise of AM inside their group,” defined Dr. David Krzeminski, EOS North America senior Additive Minds advisor.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

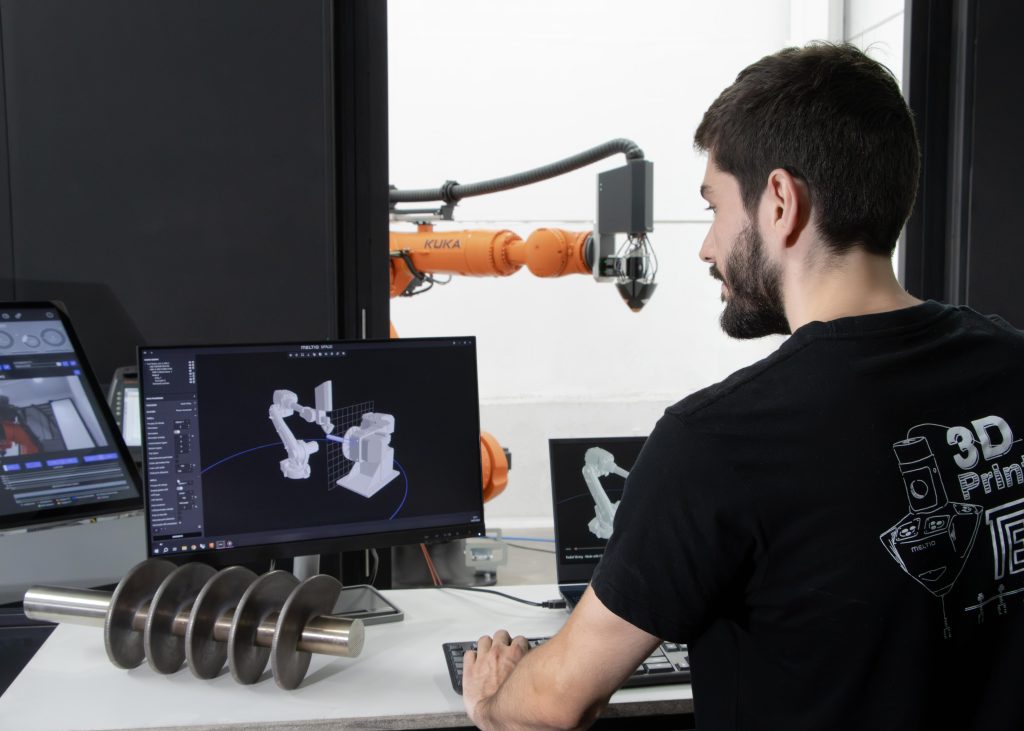

Featured picture reveals an engineer utilizing the brand new Meltio Area software program. Photograph through Meltio.

[ad_2]