[ad_1]

Time is working out! Nominate now for the 3D Printing Trade Awards 2023.

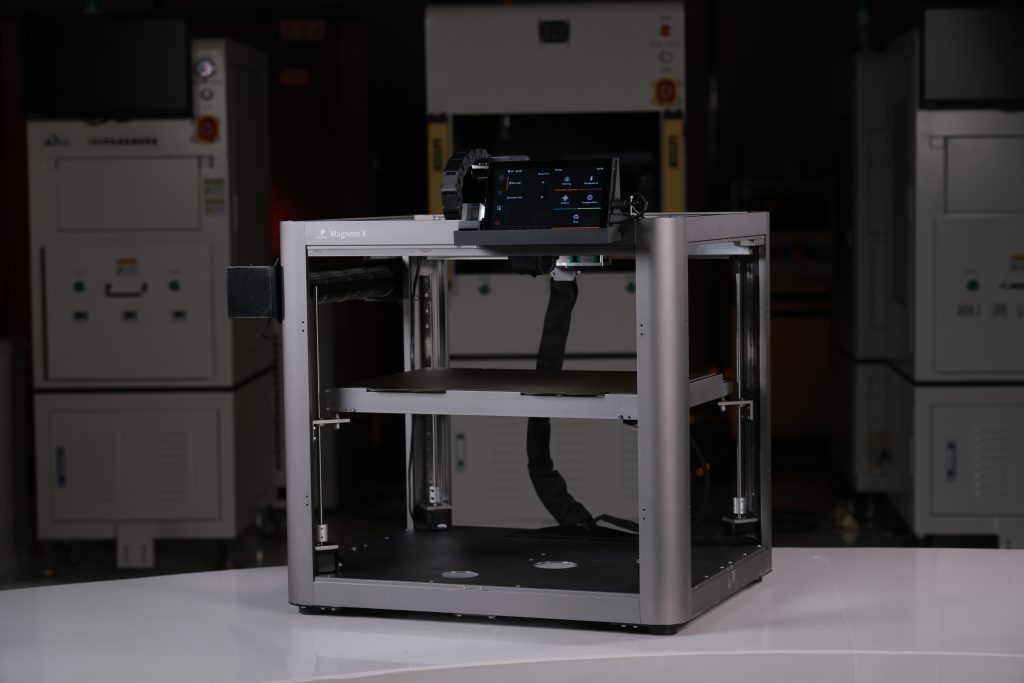

Hong Kong-based 3D printer producer Peopoly has launched the Magneto X, the world’s first MagLev-based desktop FFF 3D printer.

Casting off belts and pulleys, Peopoly’s new 3D printer employs a proprietary MagXY magnetic linear motor system for the X and Y axes. Based on Peopoly, this magnet-driven system permits high-performance 3D printing, combining quick 3D print speeds with excessive ranges of precision and reliability.

MagLev (brief for magnetic levitation) expertise is normally reserved for high-speed practice and low-noise aerospace purposes. Earlier this yr, Boston-based ultra-quiet vertical flight system developer MagLev Aero partnered with 3D printing OEM GE Additive’s AddWorks consultancy crew to develop the corporate’s proprietary MagLev HyperDrive aero propulsion platform. This magnet-powered platform is designed to be used in electrical vertical take-off and touchdown (eVTOL) plane.

Peopoly’s new MagLev 3D printer is obtainable to pre-order now by way of the corporate’s official web site, with the Magneto X set to be showcased for the primary time on the East Coast RepRap Pageant (ERRF) between September 30 and October 1.

Preliminary availability is open to clients in america, Canada, the UK, the European Union, and Australia. The primary models will start delivery in mid-November.

Key options of the Magneto X

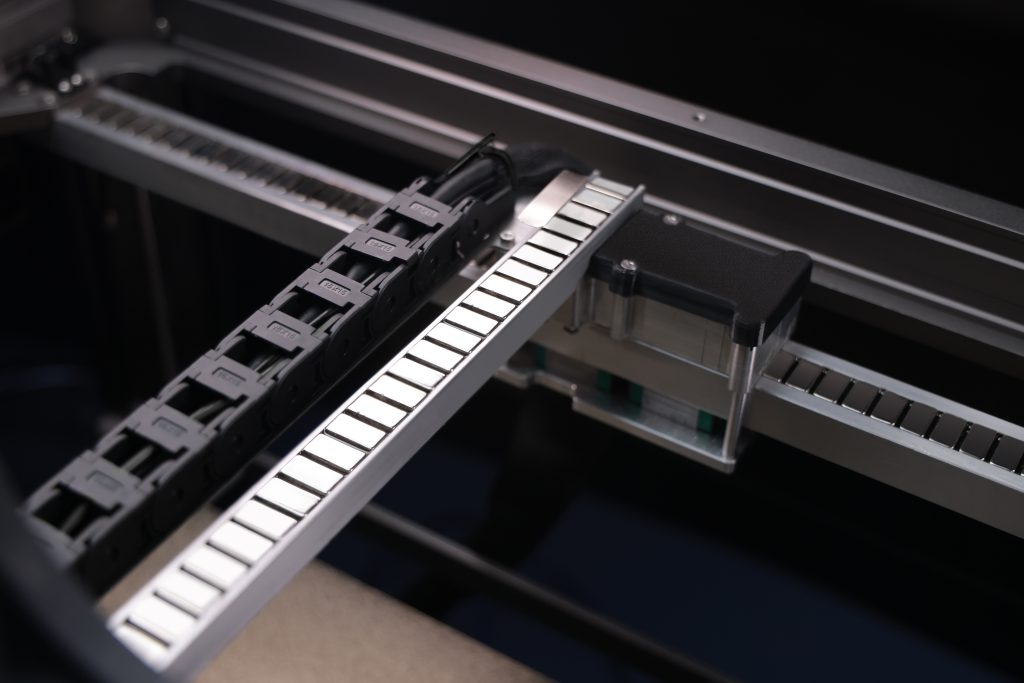

Key to the Magneto X’s performance is Peopoly’s proprietary MagXY magnetic levitation linear motor system, which controls the 3D printer’s X and Y axes. Using electromagnet expertise as a substitute of conventional belts and pulleys, this movement system is alleged to eradicate artifacts, akin to ringing and vertical effective artifacts (VCA), which might be frequent with FFF 3D printers.

Moreover, the MagXY system stays cool throughout 3D printing, enabling excessive accuracy and repeatability of three microns. That is achieved by means of a real closed-loop system with place suggestions. Based on Peopoly, the motor can self-correct misplaced steps and affords intensive optimization knowledge.

3D printer’s reliant on stepper motors can usually undergo from lowered precision beneath heavy masses, a limitation not shared by the brand new Magneto X. The Magneto X’s linear motor system can be stated to supply streamlined movement in comparison with 3D printers that use stepper motors and belts.

Furthermore, not like conventional belt-driven 3D printers, the Magneto X doesn’t require rigidity changes or extruder replacements. Decrease rail friction can be stated to increase the system’s helpful lifespan, limiting the necessity for frequent calibrations, reducing downtime and providing long-term value financial savings. Based on Peopoly, this longevity makes the MagLev 3D printer ultimate for high-production purposes akin to house companies and 3D print farms.

The Magneto X’s low-friction linear motor additionally permits for quick 3D print speeds. In reality, this new FFF 3D printer can obtain 3D print speeds of as much as 1200mm/s, with a most acceleration velocity of twenty-two,000mm2/s.

Excessive-speed 3D printing can usually end in sacrifices referring to high quality and reliability. Nonetheless, Peopoly claims that the Magneto X overcomes this drawback by means of the extrusion system’s capacity to extrude materials shortly and persistently.

The 3D printer’s Lancer extruder affords an extrusion drive of 90 Newtons and a 30mm/s filament velocity. What’s extra, it will probably obtain a most stream price of as much as 60mm3/s, because of a variable-length soften zone. Moreover, the Magneto X employs an ordinary E3D V6 volcano-style nozzle, which is simple to exchange and affords broad filament compatibility, Peopoly claims.

The Lancer extruder additionally incorporates a load sensor and a filament runout sensor. Earlier than every 3D print, the Magneto X’s 4 independently pushed Z-axis rods are calibrated by the load sensor, leveling the construct plate. The extruder then performs a 48-point mesh measurement on the construct plate, which may shortly warmth as much as 130℃, capturing detailed knowledge for calibration. This mesh knowledge is used to set the Z-offset, making certain exact computerized mattress leveling. What’s extra, the filament sensor consistently screens materials ranges, stopping 3D print failures brought on by materials depletion.

With a 400 x 300 x 300 mm construct quantity, the Magneto X is properly suited to 3D printing components for a spread of purposes. Moreover, Peopoly’s new 3D printer is supplied with a 300℃ sizzling finish and contains 0.4 mm copper and hardened metal nozzles. As such, the Magneto X is appropriate with a wide range of supplies akin to PLA, PETG, ABS, ASA, and Nylon-Carbon FIber.

The Magneto X contains a 7” IPS touchscreen consumer interface and runs Klipper firmware. This firmware is alleged to incorporate a clear code base, with the 3D printer not storing or sending knowledge within the cloud. Peopoloy claims that this ensures operability alongside full safety and IP safety. The Magneto X additionally helps Orca Slicer, PrusaSlicer, and Cura, and affords a number of connection choices together with WiFi, Ethernet, and an SD card offline mode. A 1080P HiDef digicam can be included, enabling real-time 3D print monitoring and time-lapse recording.

Extra Magneto X options embrace non-obligatory aspect enclosure panels and a high cowl, 1000W AC energy provide, and a PEI magnetic floor for fast and straightforward half elimination. Furthermore, constant cooling is ensured throughout quick 3D prints by a jetstream-style aspect fan.

Technical specification and pricing

Obtainable to pre-order now, costs for the brand new Magneto X begin at $1399 USD. Nonetheless, that is set to rise to an ordinary retail value of $1999 USD as soon as the pre-order interval ends.

Magneto X orders are set to be fulfilled as totally assembled models with Peopoly noting that, attributable to delivery constraints, customers will likely be required to mount the warmth mattress themselves. This course of takes roughly three minutes, in line with Peopoly.

| 3D Print Expertise | Fused Filament Fabrication (FFF) |

| Movement System | MagXY |

| Motion Precision | 3µ |

| Error Correction | Full Closed Loop |

| Most 3D Print Pace | 800mm/s at 0.2mm layer peak 1200mm/s at 0.1mm layer peak |

| Most Journey Pace | 1500mm/s |

| Most Acceleration | 22000mm/s2 |

| 3D Print Quantity | 400 x 300 x 300 mm |

| Construct Platform | 400 x 300 mm |

| 3D Printer Dimensions | 55 x 61 x 70 cm |

| Leveling | 48 Mesh Factors Auto-Leveling by way of Load Cell Sensor |

| Extruder Identify | Lancer |

| Most Sizzling Finish Temperature | 300℃ |

| Most Extrusion Power | 90 Newtons |

| Most Filament Pace | 30mm/s |

| Nozzle Materials | Copper, Hardened Metal |

| Supported Supplies | PLA, PETG, ABS, ASA, PA6, PA12, PA-CF, PC-GF, TPU, and extra |

| Slicer Compatibility | Orca Slicer, PrusaSlicer, Cura |

| Firmware | Klipper |

| Digital camera | 1080P, 30FPS |

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

[ad_2]