[ad_1]

This text accommodates paid for content material produced in collaboration with PowerUP.

Politicians, scientists, and {industry} stakeholders alike are constantly in search of sustainable vitality sources as a contribution to the worldwide efforts in decreasing greenhouse gasoline emissions. Nevertheless, challenges in establishing options to fossil fuels embody prices, know-how gaps, in addition to accessibility and reliability.

Biogas is broadly thought of as one puzzle piece within the larger image of tomorrow’s vitality sources: Being produced out of natural waste, it tackles each the issues of waste administration and discovering renewable vitality sources.

Nevertheless – ”The usage of biogas in vitality manufacturing is hindered by a number of components, together with an absence of effectivity of many gasoline engines themselves, that are a centerpiece within the transformation of biogas into warmth and vitality”, states Thomas Achrainer, one of many founders of PowerUP GmbH. As a longtime professional for gasoline engine providers concerning biogas energy vegetation, PowerUP has specialised in modern options to get the biogas sector prepared for the following decade.

The biogas market right this moment – an outline

Particularly in electrical energy manufacturing, biogas has been discovered as a promising different to fossil fuels, which nonetheless made up nearly all of international vitality sources in 2022: Coal alone had a share of greater than 35% that yr, adopted by pure gasoline with 22%.[1]

But, renewable vitality sources like biogas are on the rise: In 2022, the capability of biogas vitality put in globally equaled 21.5 gigawatts. In whole, the worldwide biogas market – together with purposes like cooking, heating, and, with the most important share, vitality manufacturing – was estimated to measurement USD 65.53 billion in 2023. Between 2024 and 2030, a compound annual progress fee (CAGR) of 4.2% is predicted.[2] [3]

Clearly, the course is obvious: Biogas is predicted to develop into an more and more essential think about international vitality provide. Benefits embody renewability and waste utilization, but additionally elevated stability within the vitality provide of growing nations and rural areas. Nonetheless, there’s appreciable room for enchancment.[4]

Main challenges for biogas engine operators: What are the struggles?

“Biogas usually must endure a particular processing step with the intention to make it accessible to vitality manufacturing”, says Thomas Achrainer. In spite of everything, this pure product can include generally appreciable variation in its composition. However regardless of superior processing, biogas engines must be adaptable sufficient to deal with inconsistencies throughout combustion.

Nevertheless, these will not be the one intricacies that biogas engines (or slightly, their operators) are confronted with.

Inefficient amenities

Prices are a figuring out issue relating to the adoption of renewable vitality sources. Biogas makes no exception, which is why the vitality sector must have state-of-the-art applied sciences at its disposal. Talking of gasoline engines taking middle stage in vitality manufacturing with biogas, Thomas Achrainer illustrates: “Fashionable gasoline engines are actual energy horses, as they will obtain excessive effectivity ranges when utilized in vitality manufacturing. Nevertheless, even when utilizing gasoline engines by established market leaders, there’s usually room for enchancment.”

Regardless of good effectivity ranges between 40 and 50%, biogas engines for vitality manufacturing will be additional improved and tailored to particular buyer wants. For example, the tolerance for bigger variations in gasoline high quality will be improved, circumventing the necessity for laborious gasoline preparation steps.[5]

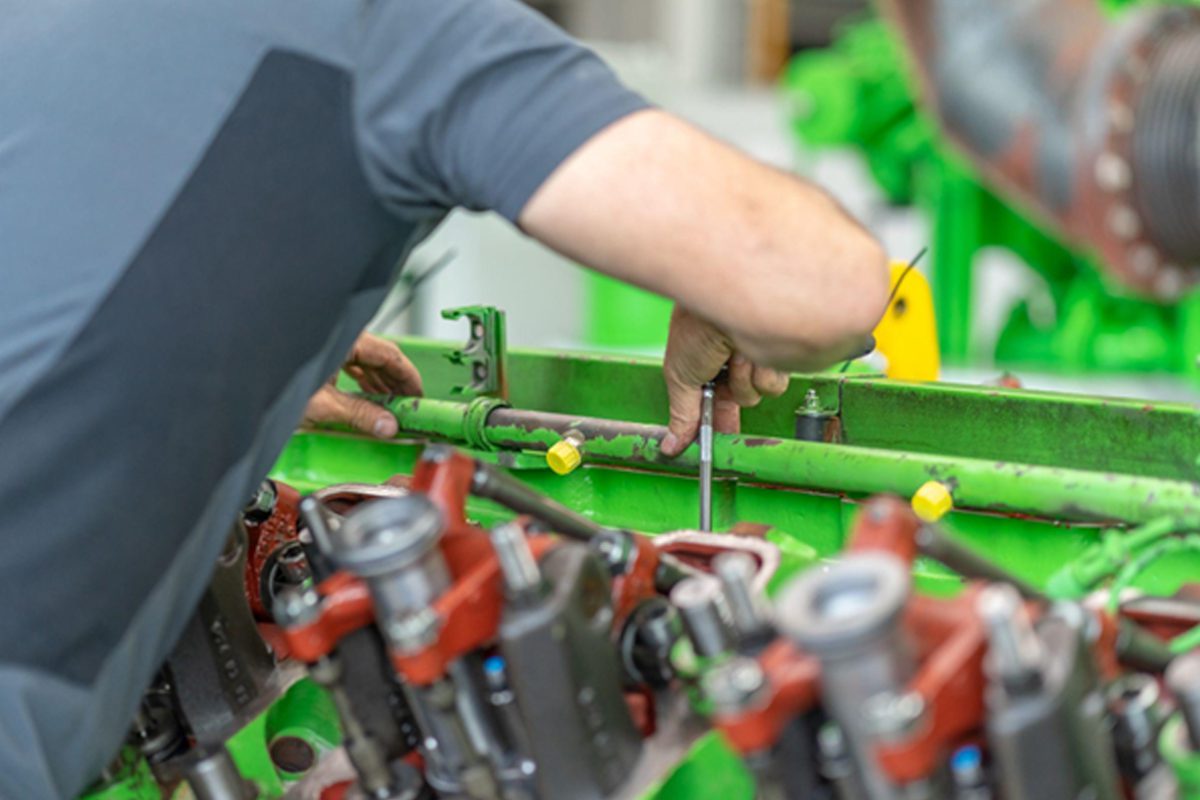

Moreover, specifically developed gasoline engine components will be included to additional enhance the effectivity of engines. These parts could embody spark plugs, blowby filters, in addition to many different elements to extend not solely effectivity, but additionally sturdiness.

Advanced upkeep

Upkeep can simply develop into a significant difficulty when working complicated amenities with massive and delicate methods. And regardless of common servicing being important to make sure longevity of expensive gasoline engines and to keep away from unplanned interruptions, it usually comes with important downtimes. That is much more true when the ability in query is situated in appreciable distance to both the gasoline engine producer or a professional service companion.

Fuel engine operators are due to this fact in search of for potentialities to both lower the prices and efforts associated to upkeep or to mix servicing with personalized upgrading of current methods.

Dated methods – expensive replacements

The common lifetime of biogas engines can prolong over greater than 25–30 years. Nevertheless, as know-how strikes on, many energy vegetation have solely dated gasoline engines at their disposal, growing each upkeep prices and susceptibility to errors. Even so: Replacements are expensive, and an premature phase-out of a gasoline engine undermines the aspiration of a sustainable vitality manufacturing.

Protecting monitor with technological progress, although, doesn’t essentially suggest frequently changing a number of elements of energy vegetation. As a substitute, potentialities to improve current methods are extraordinarily requested with the goal to make older gasoline engine generations future-proof.

Powering up biogas engines – being ready for tomorrow’s challenges

“Challenges drive innovation. With out them, we’d have stagnation as a substitute of progress”, says Thomas Achrainer. And in reality, the hurdles within the operation of biogas engines have prompted the {industry} to develop approaches to extend effectivity, reliability, and independence.

To that finish, PowerUP not solely presents upkeep providers for MWM® and INNIO Jenbacher® engines in 52 nations – the condition-based overhaul permits price and useful resource effectivity by solely exchanging these components which have truly reached the tip of their lifetime. Part replacements, then again, additionally embody PowerUP-designed gasoline engine spare components which can be in a position to additional enhance the effectivity and longevity of biogas engines – similar to blowby methods and cylinder heads.

Along with devoted spare components and improve choices for current engines, PowerUP has additionally developed PUPGEN: The mixture of an overhauled INNIO Jenbacher® Sort 3 engine and focused variations by PowerUP makes it an especially versatile whereas cost-effective addition to the corporate’s line-up.

[1] https://www.statista.com/statistics/269811/world-electricity-production-by-energy-source/

[2] https://www.statista.com/statistics/1032922/biogas-capacity-globally/

[3] https://www.grandviewresearch.com/industry-analysis/biogas-market

[4] https://energypedia.data/wiki/Advantages_and_Disadvantages_of_Biogas

[ad_2]