[ad_1]

Engineers and chemists at Lawrence Livermore Nationwide Laboratory (LLNL) and Meta have collaborated to develop a 3D printed materials that emulates the properties of organic tissues. This development has the potential to considerably influence the sphere of wearable know-how and improve the idea of “augmented humanity.”

Printed within the journal Matter, their analysis introduces a novel 3D printable resin that makes use of gentle to create clean stiffness gradients, replicating pure transitions present in organic constructions, such because the junction between bone and muscle. This addresses a big problem in creating extra real looking wearables: the mechanical disparity between delicate tissues and inflexible digital elements.

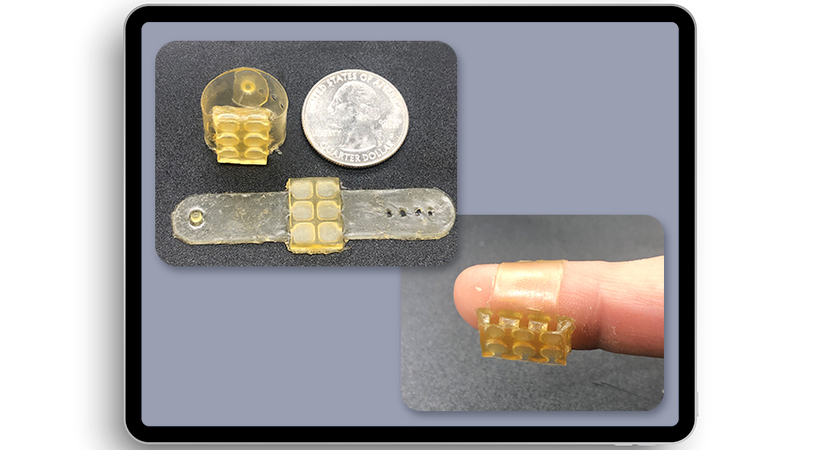

The staff demonstrated the fabric by designing a 3D printed wearable braille system able to translating textual content messages into braille immediately. By adjusting the sunshine depth through the Digital Gentle Processing 3D printing course of, they achieved steady mechanical gradients from delicate to stiff inside a single resin system.

“A ravishing function of additive manufacturing is that we are able to create these unattainable constructions, but additionally we’re considerably restricted when it comes to the fabric properties — we solely have a certain quantity of fabric that we are able to choose from,” lead writer and LLNL engineer Sijia Huang.

“One of many preliminary motivations was, ‘what if we may have the identical resin system and replicate the engineered plastic programs effortlessly by merely adjusting the sunshine depth?’ That may save a big quantity of effort and time for engineers, significantly when incorporating new properties of supplies.”

This analysis opens prospects for crafting wearable gadgets with adaptable materials properties, with potential functions in delicate robotics, energy-absorbing supplies, and wearable electronics.

Crucially, the fabric shows sturdy stability beneath each gentle and ambient circumstances, distinguishing it from conventional plastics. This improvement represents a big step ahead within the realm of variable-stiffness polymer supplies with long-term sturdiness.

You possibly can learn the total analysis paper, titled “One-pot ternary sequential reactions for photopatterned gradient multimaterials” over at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.

[ad_2]