[ad_1]

Researchers from Chalmers College of Expertise, Sweden, have pioneered a 3D printed plasmonic plastic – a composite materials with intriguing optical properties. This improvement heralds 3D printed optical hydrogen sensors, pivotal for advancing inexperienced vitality and trade sectors.

Beforehand, plasmonic steel nanoparticles, recognized for his or her potent interplay with gentle, have been primarily utilized on flat surfaces and necessitated complicated cleanroom lab manufacturing. Nonetheless, this multi-year enterprise aimed toward manufacturing 3D plasmonic objects sustainably, leveraging the inherent malleability and cost-effectiveness of plastics, coupled with 3D printing know-how.

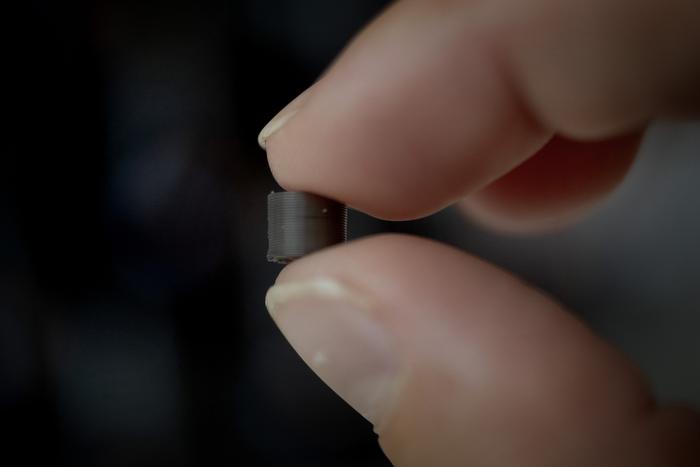

The ensuing plasmonic plastic includes a polymer and colloidal steel nanoparticles, enabling 3D printing of objects starting from a fraction of a gram to a number of kilograms. The main focus was on fabricating plasmonic sensors able to detecting hydrogen, pioneering a novel optical sensor realm primarily based on plasmons.

“Various kinds of sensors are wanted to hurry up improvement in medication, or the usage of hydrogen in its place carbon-free gas,” mentioned Christoph Langhammer, professor on the Division of Physics, who led the venture.

“The interaction between the polymer and nanoparticles is the important thing issue when these sensors are fabricated from plasmonic plastic. In sensor purposes, this kind of plastic not solely allows additive manufacturing, in addition to scalability within the materials manufacturing course of, however has the extra vital perform of filtering out all molecules besides the smallest ones – in our software, these are the hydrogen molecules we need to detect. This prevents the sensor from deactivating over time,”

Apparently, the sensor’s steel nanoparticles change colour upon hydrogen contact, offering instant alerts if hydrogen ranges escalate, important for managing this doubtlessly flammable fuel.

This analysis not solely unlocks the potential for scalable sensor manufacturing but in addition expands the horizon for plasmonic plastics in various fields like healthcare, wearable know-how, and maybe even the realms of artwork and trend.

Supply: eurekalert.org

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.

[ad_2]