[ad_1]

A crew of scientists from the Max Planck Institute for Informatics in Saarbrücken, Germany, and the College of California at Davis, have developed a novel course of for 3D printing capsules that may launch pharmaceutical medication at predetermined speeds.

The analysis group chief offered insights to 3D Printing Business on the implications of the approach.

In a lately printed analysis paper led by Dr. Vahid Babaei from the Max Planck Institute and Prof. Julian Panetta of UC Davis, the crew demonstrated how capsules will be 3D printed with particular shapes to find out the pace at which they dissolve throughout the human physique.

Geometric shapes are simpler to regulate than different timed drug-delivery strategies akin to intravenous infusion. Thus, given the significance of controlling pharmaceutical drug ranges in sufferers, It’s claimed that this new methodology has important potential throughout the pharmaceutical trade. Past pharmaceutics, the manufacturing of catalytic our bodies and coarse granular fertilizers are additionally pointed to as potential functions.

“I’m satisfied that time of care, personalised drugs is across the nook, and 3D printing will play a serious position,” commented Dr. Babaei, Analysis Group Chief, Synthetic Intelligence-Aided Design and Manufacturing Group, at Max Planck Institute for Informatics.

A analysis first for inverse design technique

The researchers mixed superior computational strategies, mathematical modeling, and FDM primarily based 3D printing know-how when testing and evaluating this new course of.

The analysis crew performed simulations of the designs developed with topology optimization. Then the ahead simulations have been inverted to discover a particular form that reveals sure dissolution properties. Sensible experiments then confirmed these predictions concerning dissolution. The analysis crew says they’re the primary to make the most of an inverse design technique to search out the specified form from launch habits primarily based on topology optimization.

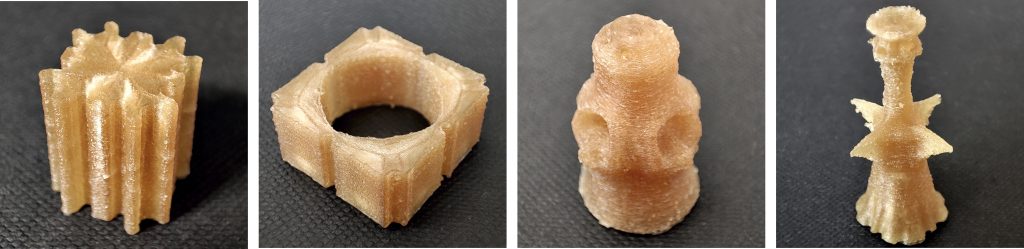

When conducting the experiments, the researchers first 3D printed the specified elements utilizing a Prusa i3 MK3s FDM 3D printer outfitted with a 0.2 mm Kaika nozzle from Tecdia Co. AquaSys 120 from Infinite Supplies Options, a water soluble filament usually used for assist constructions, was additionally utilized.

As soon as printed, the elements have been positioned in distilled water. A digicam system was then used to measure the pace at which the items dissolved. Whereas different, high-cost and specialist gear is usually used to measure dissolution charges, an image-based system was employed right here because it was a lot quicker and less complicated for the scientists to arrange.

Finally, the measured launch curves have been very near the specified values. This validated the inverse design technique predictions, and confirmed that particular shapes can be utilized to find out particular launch charges for medication.

While the analysis crew has not but quantified the entire addressable marketplace for this new tablet manufacturing methodology, they’ve patented their work. Dr. Babaei asserts that “Our group cares deeply about placing our analysis into apply.” Certainly, the crew has already launched a spin-off challenge for the laser trade referred to as Oraclase.

Pharmaceutical functions for 3D printing

Leveraging 3D printing know-how for pharmaceutical functions has an inexpensive historical past. In 2016, Aprecia Prescription drugs introduced U.S. Meals and Drug Administration approval of their Spritam remedy – the primary 3D printed pharmaceutical to finish the FDA course of. Designed to deal with a spread of seizures, Spritam is 3D printed as an immediately dissoluble pill, making the remedy extra accessible to sufferers who would in any other case have problem swallowing a tablet.

Regardless of some similarities, there are actually clear distinctions between Aprecia’s providing and this new shape-oriented course of. “To my understanding, Spritam has a single dissolution mode – a quick, instant one,” commented Dr. Babaei. “In our case, we let the consumer virtually draw any launch profile (quick or in any other case) after which compute the form accordingly.”

Elsewhere, in 2020 a analysis crew from Greece and Italy leveraged semi-solid extrusion 3D printing to edit tablets, permitting for customizable and affected person particular drug launch charges. Right here, moderately than 3D printing the capsules, the scientists used 3D printing know-how to partially coat the tablets with glycerides. By controlling the coating traits, the researchers succeeded in exactly regulating the discharge of two Lively Pharmaceutical Elements (APIs) throughout the tablets. In accordance with the authors of the examine, this allowed for “personalised drug launch charges in line with the affected person’s wants.”

Subscribe to the 3D Printing Business publication to make sure you sustain with the newest 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits a 3D printed tablet. Picture by way of Max Planck Institute for Informatics.

[ad_2]