[ad_1]

A brand new aluminium alloy powder, designed particularly for additive manufacturing, has been unveiled on the AM Conclave convention in Abu Dhabi.

The alloy powder, named AMALLOY, has been developed by the Know-how Innovation Institute (TII), and is the primary metallic additive manufacturing feedstock designed within the Center East. Meant to be used on laser beam powder mattress fusion techniques, the low-cost, high-strength aluminium alloy has wonderful printability and efficiency.

In comparison with the extensively accessible AlSi10Mg alloys, AMALLOY reveals a 33% improve in power with out compromising ductility. This makes it an excellent selection for functions requiring each light-weight properties and excessive power.

One in every of AMALLOY’s standout options is its low scorching crack susceptibility coefficient, because of its distinctive chemical composition and metallurgical compounds. This ends in distinctive power with out the chance of scorching cracking. Atom Probe Tomography has revealed nano-precipitates within the aluminum microstructure, additional enhancing the alloy’s power.

Past its mechanical prowess, AMALLOY has demonstrated thermal stability as much as 300ºC, making it appropriate for high-temperature environments.

TII’s built-in computational and experimental framework, which covers alloy design, experimentation, optimization, and extra, has been instrumental in AMALLOY’s success, resulting in a patent submitting with the US Patent Workplace. TII plans to use this framework to develop alloys for varied metals and conventional manufacturing processes.

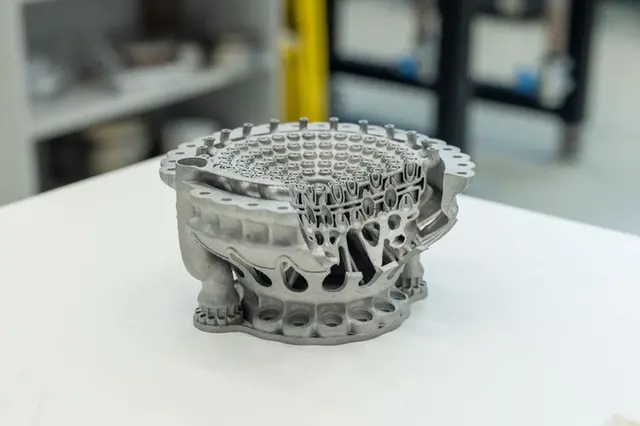

The goal clients for AMALLOY consists of world metallic powder producers, with potential licensing alternatives. Use instances vary from aerospace and aviation parts to high-strength engine brackets.

In its as-printed state, AMALLOY gives spectacular properties resembling excessive relative density, low scorching crack susceptibility, Vickers hardness, yield power, and supreme tensile power.

The event framework will additional improve AMALLOY, paving the way in which for high-strength aluminum alloys tailor-made for high-temperature functions. The fabric guarantees new prospects throughout industries resembling aerospace, house, oil and fuel, and nuclear.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.

[ad_2]