[ad_1]

A worldwide consortium comprising main industrial firms like Evo3D, Rolls-Royce, Filamentive, AI Construct, and Baker Hughes has initiated a venture aiming to rework UK’s industrial additive manufacturing. The Nationwide Manufacturing Institute Scotland (NMIS) operated by the College of Strathclyde and part of the Excessive Worth Manufacturing Catapult (HVMC) additionally performs an vital position on this venture.

The venture dubbed, Evo One ‘giant format additive manufacturing’ (LFAM) is supported by Innovate UK, offering a grant of £1.1 million in whole. The Evo One LFAM venture is on the cusp of growing “a cutting-edge 3D printer system.” This new system has the potential to reinforce UK’s manufacturing capabilities by introducing superior processes for crafting high-value parts.

“We have now an enormous alternative within the UK to be a frontrunner in giant format additive manufacturing. Placing the fitting know-how in as many producers’ fingers as we will is a superb base to construct on, and having a UK-based OEM is step one in that route. With the fitting instruments at our disposal, we will encourage extra producers of all sizes to embrace the newest manufacturing strategies and applied sciences, paving the best way for a extra sustainable and globally aggressive sector. Our group, with specialisms starting from digital course of administration to forging and forming, is supporting companies throughout Scotland and the UK to innovate and rework what they do,” mentioned Stephen Fitzpatrick, Director of Digital Manufacturing unit at NMIS.

Challenge supplies elevated reliability and productiveness for LFAM 3D printers

Using the LFAM methodology, the business 3D printing method excels within the fabrication of sizeable polymer parts, presenting a notable benefit. Key sectors together with aerospace, automotive, vitality, and marine are poised to reap substantial benefits from this strategic pursuit. Though international locations equivalent to america, Germany, and China have readily adopted LFAM, the UK’s foothold within the worldwide additive manufacturing enviornment registers at a modest 5%. In response, the UK authorities has set a goal to extend its market presence to eight% by 2025.

Presently, the UK lacks home producers of large-format 3D printers, which limits nationwide competitiveness on this quickly evolving panorama. The Evo One LFAM initiative goals to mitigate these limitations and design an answer tailor-made to the UK’s market wants. The venture group targets substantial enhancements, together with a 60% enhance in reliability, a 50% increase in productiveness, a 30% discount in coaching and upkeep bills, and an 80% minimize in materials waste.

The NMIS group will provide complete assist throughout numerous specialised areas, together with materials evaluation, design, and additive manufacturing processes. It’s going to additionally oversee system validation, verification, and the utilization of high-value supplies. Rolls-Royce and Baker Hughes will conduct system testing upon readiness, whereas AI Construct will assist in advancing slicing know-how growth.

Upon venture completion, Evo3D seeks to create RapidFusion, unveiling the UK’s first unique gear producer (OEM) in LFAM. Doing so will bolster the availability chain, relocate very important manufacturing capabilities, and equip UK producers with a dynamic platform to leverage Business 4.0, says the consortium.

Massive format 3D printing techniques

German plastic equipment OEM KraussMaffei launched its new large-scale extrusion-based 3D printer, the powerPrint. Tailor-made for environment friendly additive manufacturing of sizable, near-net-shape parts, powerPrint integrates swift setup, excessive output, and fast 3D printing speeds. Unveiled on the Okay 2022 commerce present, it caters to industries demanding substantial, constantly high-quality large-format objects.

US 3D printer producer 3D Methods and Japanese product design firm SWANY collaborated to advertise large-format pellet extrusion 3D printing in Japan. SWANY’s demo middle, opening in October in Nagano Prefecture, will function 3D Methods’ EXT 1070 Titan Pellet 3D printer, showcasing pellet-extrusion’s potential for additive and subtractive manufacturing of sizable components. The middle will provide 3D printing providers and design assist, whereas each firms will collectively develop 3D printing parameters for mass manufacturing and recycled pellets, aligned with the Upcycling Workspace (UCWS) initiative in Nagano Prefecture.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a collection of roles within the trade.

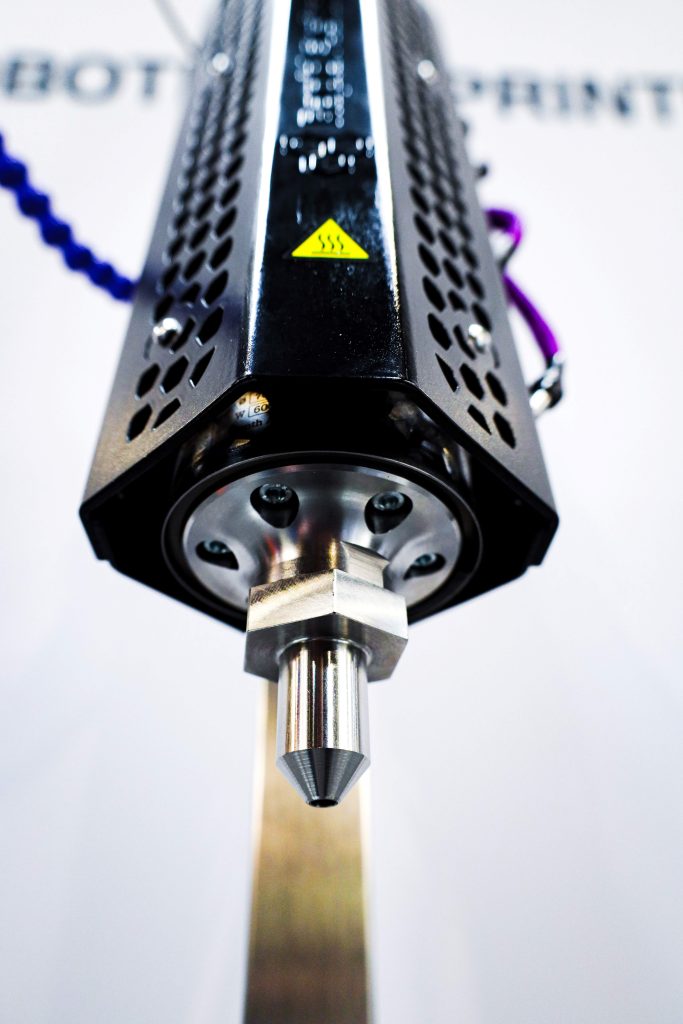

Featured picture exhibits Speedy Fusion Pellet Extruder. Picture by way of Evo3D.

[ad_2]