[ad_1]

Researchers have demonstrated a way to upcycle end-of-life battery waste into supplies that can be utilized for ‘subsequent technology’ battery cathodes.

And the group behiind the analysis suggests the event of this functionality ought to presage a shift in focus, by way of the way in which circularity ideas are adopted on this area.

Professor Slater of the College of Birmingham stated: “The problem is not about recycling. Battery chemistry has moved on significantly within the final decade, and, as first-generation EV batteries attain the top of their lives, their elements must be upcycled to ship chemistries that may be reused within the newer batteries.”

On this newest work, his staff has used the recovered materials from end-of-life EV batteries to synthesize compounds with a disordered rocksalt (DRX) construction.

DRX supplies are seen as a promising different to the common layered construction of typical cathode supplies, as they improve the capability of the cathode, permitting growth of upper power density rechargable Lithium ion batteries.

The researchers imagine that is the primary time such supplies have been produced from recycled EV battery feedstock.

Outcomes of electrochemical testing confirmed excessive efficiency, stated the group, similar to supplies ready from typical excessive purity reagents, demonstrating the applicability of this new strategy.

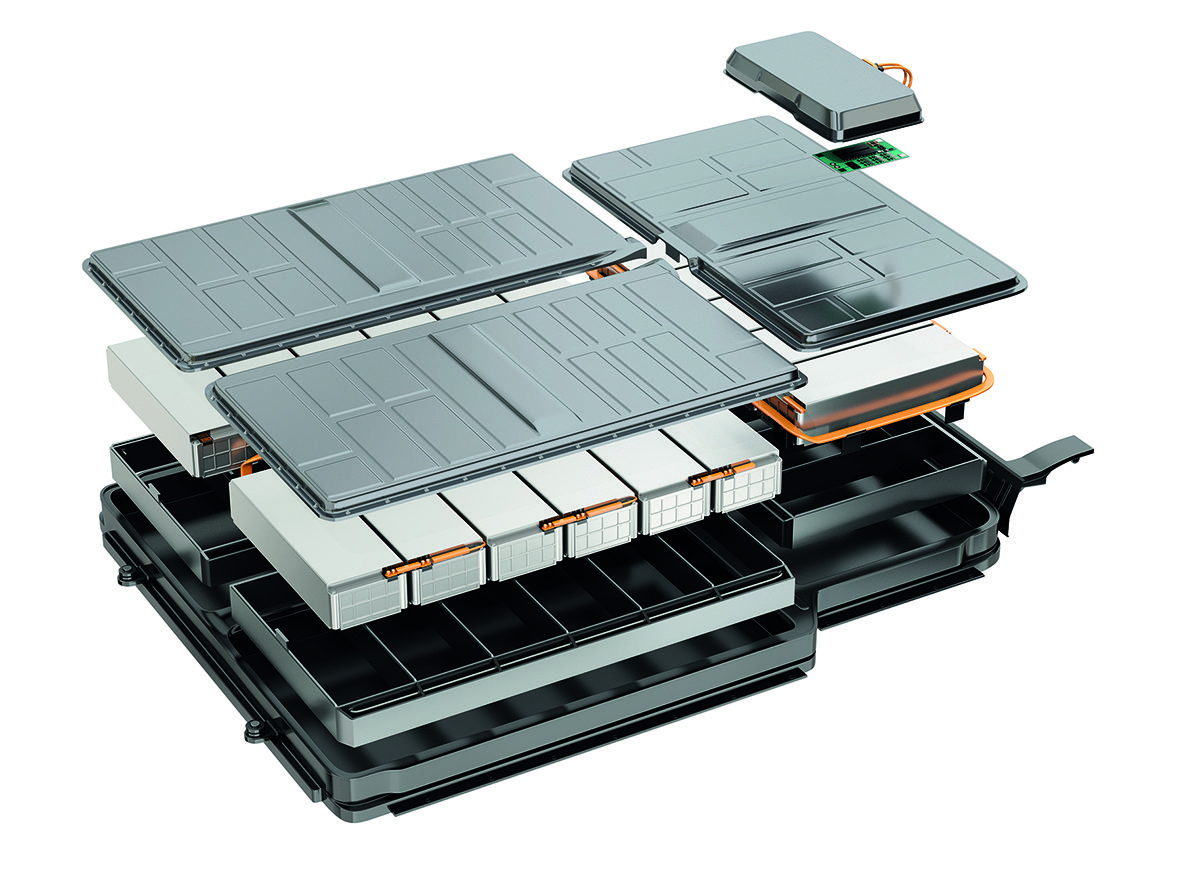

The cathode, which is the a part of batteries that offer electrical present, is the first limitation for attaining the high-energy, low-cost lithium ion (LI) batteries wanted for the transition to zero emissions at tailpipe that will likely be required to cut back international CO2 emissions and mitigate international warming.

For electrical car (EV) batteries, the problem is to design a excessive power battery cathode that can keep its means to discharge electrical energy over a lot of charge-discharge cycles. For recycling consultants, the problem is to design recycling processes for lithium-ion batteries after they attain the top of their helpful life.

The researchers say they’ve taken these challenges one step additional, by tasking themselves with the target of ‘upcycling’ recovered battery supplies, so the waste streams from present EV batteries can be utilized to fabricate new high-performance batteries.

The analysis, which is revealed in ChemRxiV, is a growth of earlier work demonstrating ascorbic acid (Vitamin C) can be utilized as a leaching agent, changing the necessity for hazardous chemical compounds in cathode recycling.

The analysis staff led by Professor Peter Slater has now proven recycled materials from a cathode containing lithium manganese oxide (LMO) and nickel-rich ‘layered’ oxide (LO), may be upcycled to lithium manganese nickel oxides (LMNO) – a excessive voltage cathode materials, which is attracting excessive ranges of business curiosity.

For the present examine the researchers used citric acid (a pure part of citrus fruits) as a leaching agent to additional scale back the variety of steps within the course of, which they utilized to cathodes from an end-of-life Gen 1 Nissan Leaf (2011 mannequin, 40,000 miles), and used the recovered LMO as a place to begin for LMNO synthesis.

They then used the recovered materials to synthesize compounds with a DRX construction.

The analysis staff is engaged on various strategies for recycling and upcycling battery cathode supplies, and is in search of long-term companions for pilot research, ship applied sciences to current infrastructure, or collaborate on additional analysis to develop novel approaches.

[ad_2]